Labaru

-

Menene banbanci tsakanin gwal da filastik a kan jirgin PCB? Sakamakon ya kasance abin mamaki

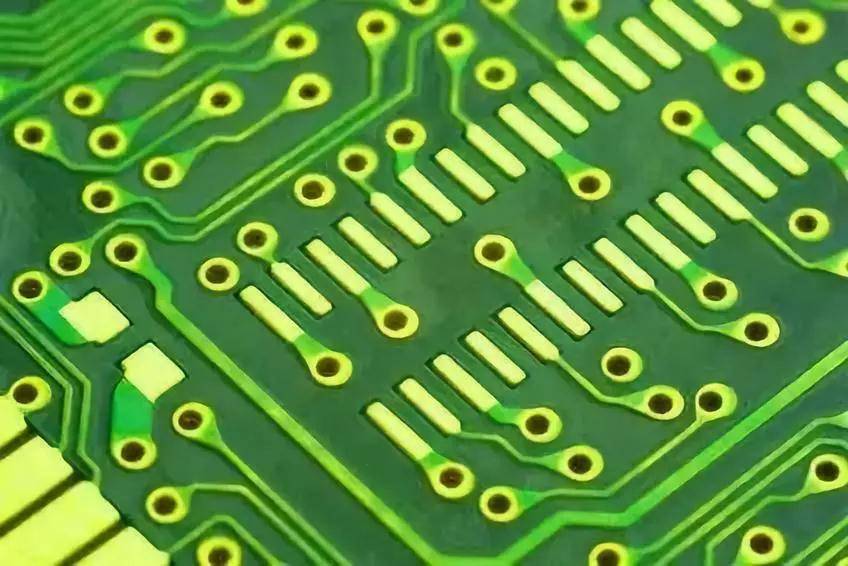

Yawancin 'yan wasan DIY zasu gano cewa samfuran kwamiti daban-daban akan kasuwa suna amfani da m launuka launuka iri-iri. Za a iya samun launuka na yau da kullun launuka, kore, shuɗi, rawaya, shunayya, ja, da launin ruwan kasa. Wasu masana'antun sun inganta fararen fata, ruwan hoda da sauran launuka daban-daban na PCB. A cikin traditio ...Kara karantawa -

Me yasa PCB ta hanyar ramuka zasu yi ramuka? Shin kun san wani ilimi?

Ramin wasan bincike ta hanyar rami kuma ana kiranta ta via rami. Don biyan bukatun abokin ciniki, hukumar ta katangar ta shiga rami dole ne a shigar da ita. Bayan da yawa na aiki, da na gargajiya kayan gargajiya ne aka canza tsari, kuma da'irar jirgin saman Sold Skumar Mask da kuma an kammala su da wh ...Kara karantawa -

A cikin 2021, matsayin Quo da damar samun PCB

Girman Motoci na Motoci na Kasuwanci na gida, rarrabawa da fa'ida wuri mai kyau 1. Daga allon kasuwa da aka saba da su guda biliyan guda biliyan 10, kuma wuraren aikace-aikacen da aka yi da karamin lambun HDI na radar. 2. A wannan st ...Kara karantawa -

Tana da hannayen da suka shafi "Emboiry" akan PCB na sararin samaniya

Dan wasan mai shekaru 39 "Welder" Wang yana da hannayen fari da kuma m hannun. A cikin shekaru 15 da suka gabata, wannan hannayen da suka dace sun shiga cikin kera ayyukan kaya sama da 10, ciki har da sanannen jerin Shenzhou da Chang'e Ser ...Kara karantawa -

Yadda za a yi la'akari da daidaitawa lokacin da ke tsara tsarin ƙirar PCB mai sauri?

A lokacin da ƙirar da'irar PCB mai sauri-sauri, wanda ya dace daidai shine ɗayan abubuwan ƙira. Darajar rashin daidaituwa tana da cikakkiyar dangantaka da hanyar watsa shirye-shirye, kamar tafiya a farfajiya ta ƙasa (microbpline / sau biyu), nesa daga Layer Layer (Powe ...Kara karantawa -

Jawina Clad Laminate shine ainihin sinadari

Tsarin masana'antar na clad laminate laminate (ccl) shine lalata karfafa kayan tare da resin kwayoyin da bushewa ta don samar da wani shiri. Wani fanko da aka yi da yawa pigpregs jere tare, daya ko biyu an rufe shi da jan karfe na katako, da kuma kayan da aka kame ta hanyar matsara mai zafi. F ...Kara karantawa -

Wasu matsaloli masu wahala da ke da alaƙa da babban PCB mai sauri, shin kun warware shakku?

Daga PCB duniya 1. Yadda za a yi la'akari da daidaitawa lokacin da ke tsara tsarin ƙirar PCB mai sauri? A lokacin da ƙirar da'irar PCB mai sauri-sauri, wanda ya dace daidai shine ɗayan abubuwan ƙira. Darajar rashin daidaituwa tana da cikakkiyar dangantaka da hanyar watsajiyar, kamar tafiya akan su ...Kara karantawa -

Wane damar ci gaba ne masana'antar PCB da ke da gaba?

Daga PCB - - 01 The Direction of Samuwar samarwa yana canzawa da ikon samarwa shine fadada samarwa da haɓaka samfurori, daga ƙananan ƙananan zuwa ƙarshen. A lokaci guda, abokan cinikin ƙasa marasa ƙarfi kada suyi mai da hankali ...Kara karantawa -

A cewar kayan aiki na PCB, an raba shi cikin nau'ikan masu zuwa:

A cewar kayan aiki na PCB, an raba shi cikin nau'ikan masu zuwa: 1. Wani lokaci na Phenolog, wanda da dai sauransu, da sauransu.Kara karantawa -

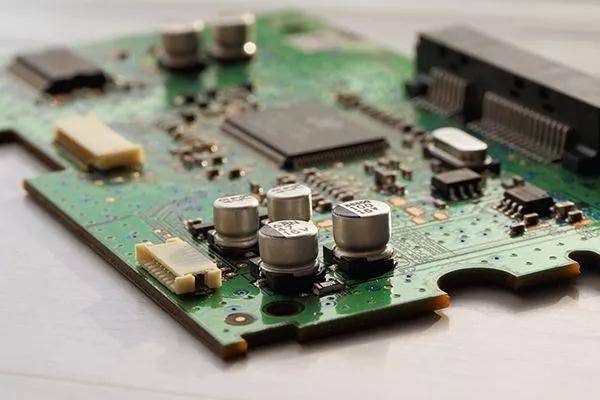

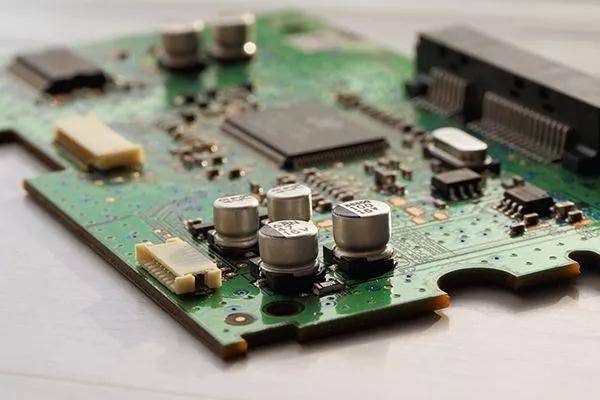

Cob mai laushi mai laushi

1. Mene ne kayan kunshin mai laushi mai laushi na iya ganin cewa akwai wani abu baƙar fata akan wasu allon da'ira, don haka menene wannan abin? Me yasa yake a allon jirgin? Menene sakamakon? A zahiri, wannan nau'in kunshin ne. Sau da yawa muna kira shi "kunshin mai taushi". An ce mai laushi kayan aiki ne ...Kara karantawa -

Shin ka san bambanci tsakanin kayan na PCB?

-Krrit PCB duniya, masu haɗari na kayan, wanda kuma aka sani da harshen wuta, juriya na wuta, flame juriya da sauran haɗari, shine kimanta ikon kayan don tsayayya da konewa. Da harshen wuta ya ...Kara karantawa -

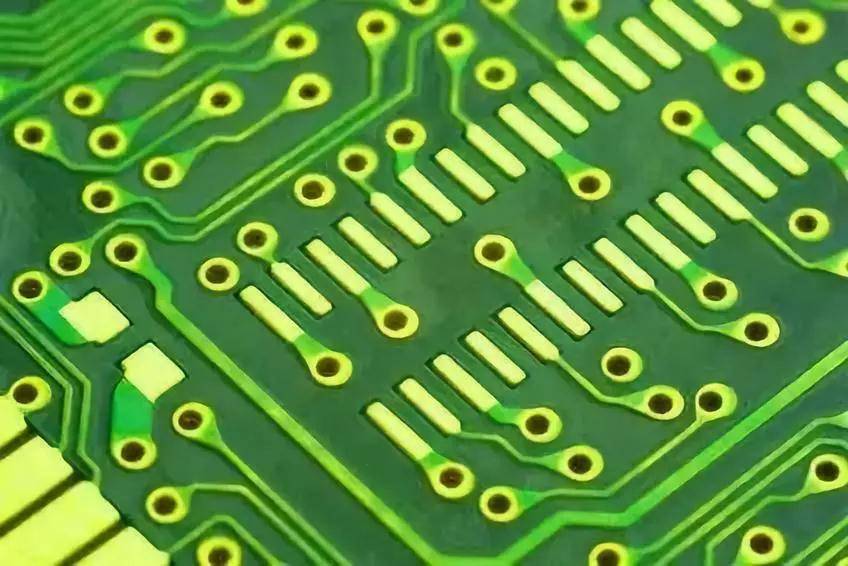

Tsarin PCB

Dangane da adadin yadudduka na PCB, an raba zuwa gefe guda, gefe biyu, da allon katako-Layer. Kwamitin kwamitin uku ba ɗaya bane. Babu wani tsari na ciki na gefe-gefe da bangarori biyu-biyu, m yankan hakoma-bibiya tsari. Bakin Mullieight zasu ...Kara karantawa