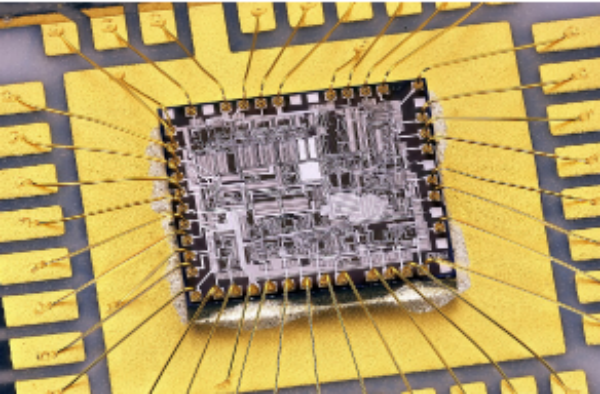

I-wire bonding- indlela yokufaka i-chip ku-PCB

Kunama-chips angama-500 kuye kwayi-1,200 axhunywe kusiluli ngasinye ngaphambi kokuphela kwenqubo. Ukuze usebenzise lawa maships lapho kudingeka khona, iwafa idinga ukusikwa ibe ama-chips ngamanye bese ixhunywa ngaphandle futhi ivulwe. Ngalesi sikhathi, indlela yokuxhuma izintambo (izindlela zokudlulisela amasignali kagesi) ibizwa ngokuthi i-wire bonding.

Impahla ye-wirebonding: igolide / i-aluminium / yethusi

I-Material ye-wirebonding inqunywa ngokucubungulisisa amapharamitha e-welding ahlukahlukene futhi uwahlanganise abe indlela efaneleke kakhulu. Amapharamitha okukhulunywa ngawo lapha ahlanganisa izinto eziningi, okuhlanganisa uhlobo lomkhiqizo we-semiconductor, uhlobo lokupakisha, usayizi wephedi, ububanzi bomthofu wensimbi, indlela yokushisela, kanye nezinkomba zokwethembeka ezifana namandla aqinile kanye nobude bomthofu wensimbi. Izinto ezijwayelekile zokuhola zensimbi zihlanganisa igolide, i-aluminium nethusi. Phakathi kwazo, ucingo lwegolide lusetshenziswa kakhulu ekufakweni kwe-semiconductor.

I-Gold Wire inokuhamba kahle kukagesi, izinzile kumakhemikhali, futhi inokumelana nokugqwala okuqinile. Kodwa-ke, okubi kakhulu kocingo lwe-aluminium, olwalusetshenziswa kakhulu ezinsukwini zakuqala, ukuthi kwakulula ukugqwala. Ngaphezu kwalokho, ukuqina kwentambo yegolide kunamandla, ngakho-ke ingakhiwa kahle ibe yibhola ekuhlanganiseni okuyinhloko, futhi ingakha ngokufanelekile iluphu eholayo eyisiyingi (Iluphu, kusukela ekuhlanganiseni okuyinhloko kuya ekuhlanganisweni kwesibili) ekuhlanganiseni kwesibili. isimo esakhiwe).

I-Aluminium Wire inobubanzi obukhudlwana kanye nephimbo elikhudlwana kunentambo yegolide. Ngakho-ke, ngisho noma ucingo lwegolide oluhlanzekile lusetshenziselwa ukwakha iluphu yokuhola, ngeke luphuke, kodwa ucingo oluhlanzekile lwe-aluminium luzophuka kalula, ngakho luzohlanganiswa ne-silicon noma i-magnesium ukuze wenze i-alloy. Intambo ye-aluminium isetshenziswa kakhulu ekufakweni kwezinga lokushisa eliphezulu (njenge-Hermetic) noma izindlela ze-ultrasonic lapho intambo yegolide ingakwazi ukusetshenziswa.

Nakuba ucingo lwethusi lushibhile, ukuqina kwalo kuphakeme kakhulu. Uma ubulukhuni buphezulu kakhulu, ngeke kube lula ukwenza isimo sebhola, futhi kunemikhawulo eminingi lapho wenza izihibe zokuhola. Ngaphezu kwalokho, ingcindezi kufanele ifakwe ku-chip pad ngesikhathi senqubo yokubopha ibhola. Uma ubulukhuni buphezulu kakhulu, imifantu izovela efilimu phansi kwepadi. Ukwengeza, kuzoba khona "i-peeling" into lapho ungqimba lwe-pad oluxhunywe ngokuqinile luhlakazeka. Noma kunjalo, njengoba izintambo zensimbi ze-chip zenziwe ngethusi, kunomkhuba okhulayo wokusebenzisa ucingo lwethusi kulezi zinsuku. Yiqiniso, ukuze unqobe ukushiyeka kocingo lwethusi, kuvame ukuxutshwa nenani elincane lezinye izinto zokwakha i-alloy bese isetshenziswa.