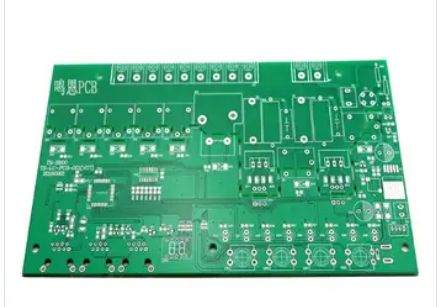

I-PCB impedance isho imingcele yokumelana nokusabela, edlala indima ye-anobstruction ekushintsheni kwamanje. Ekukhiqizeni ibhodi lesifunda se-pcb, ukwelashwa kwe-impedance kubalulekile. Ngakho-ke uyazi ukuthi kungani amabhodi wesifunda se-PCB adinga ukwenza i-impedance?

1, PCB wesifunda ibhodi phansi ukuze ucabangele ukufakwa izingxenye electronic, conductivity kagesi kanye isignali ukudluliswa ukusebenza ngemva kokufakwa, ngakho kuzodinga ephansi impedance, ngcono, resistivity ingaphansi 1 × 10-6 per isentimitha square ngezansi.

I-2, ibhodi lesifunda le-PCB ohlelweni lokukhiqiza ukuzwa ukucwila kwethusi, i-tin plating (noma i-electroless plating, noma i-hot spray tin), amalunga e-solder kanye nezinye izixhumanisi zokukhiqiza inqubo, nezinto ezisetshenziswa kulezi zixhumanisi kumele ziqinisekise ukuthi i-resistivity phansi, ukuze kuqinisekiswe ukuthi i-impedance yonke yebhodi lesifunda le-PCB iphansi ukuze ihlangabezane nezidingo zekhwalithi yomkhiqizo, ingasebenza ngokujwayelekile.

I-3, i-tinning yebhodi le-PCB yiyona ethambekele kakhulu ezinkingeni ekukhiqizeni ibhodi lesifunda lonke, futhi iyisixhumanisi esiyinhloko esithinta i-impedance. Iphutha elikhulu kakhulu lekhemikhali ye-tin plating layer ukuguquguquka okulula (kokubili i-oxidation elula noma i-delixing), i-brazing engalungile, okuzoholela ekushiseleni okunzima kwebhodi lesifunda, ukuvinjelwa okuphezulu okuholela ekuqhubeni kahle kukagesi noma ukungazinzi komsebenzi wonke webhodi.

I-4, ibhodi lesifunda le-PCB ku-conductor lizoba nokudluliswa kwesignali okuhlukahlukene, lapho lithuthukisa izinga lokudlulisela futhi kufanele likhulise imvamisa yalo, ulayini ngokwawo uma ukucwiliswa, ukushuba kwe-laminated, ububanzi bezintambo nezinye izici zihlukile, kuzodala i-impedance. kuwufanele ukushintsha, ukuze ukuhlanekezela isignali, okuholela ekwehleni ukusebenza kwebhodi, ngakho udinga ukulawula ukubaluleka impedance ebangeni elithile.