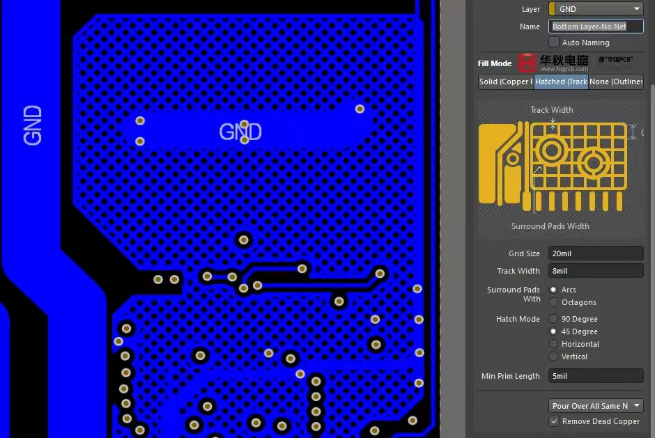

Ngemuva kwakho konke okuqukethwe kwe-PCB kwe-PCB yakhelwe, kuvame ukwenza igxathu elingukhiye lesinyathelo sokugcina - ukubeka ithusi.

Ngakho-ke kungani wenza ithusi lokubeka ekugcineni? Awukwazi yini ukukubeka phansi?

Nge-PCB, indima ye-Copper Paving imaningi impela, njengokunciphisa amandla emhlabathini kanye nokwenza ngcono ikhono lokulwa nokuphazamisa; Exhunywe ngocingo lomhlabathi, yehlisa indawo ye-loop; Futhi usize ngokupholisa, njalonjalo.

I-1, yethusi inganciphisa umkhawulo womhlaba, futhi inikeze ukuvikela okuvikelekile kanye nokucindezela komsindo.

Kunemisinga eminingi ephakeme ye-Pulse emibuthanweni yedijithali, ngakho-ke kuyadingeka kakhulu ukunciphisa amandla emhlabathini. Ukubekwa kweCopper kuyindlela ejwayelekile yokunciphisa ukubulawa komhlaba.

I-Copper inganciphisa ukumelana kocingo olusemhlabathini ngokwandisa indawo ye-Cross-purcle yesigaba somhlaba. Noma anciphise ubude bentambo yomhlabathi, wehlise ukwehla kocingo lomhlabathi, futhi ngaleyo ndlela wehlise ukungafani kocingo lomhlabathi; Ungalawula futhi amandla ocingo lomhlabathi, ukuze inani le-capacitance lomhlabathi likhuphuke ngokufanele, ukuze uthuthukise ukuqina kukagesi kocingo lomhlabathi futhi kunciphise ukungafani kocingo lomhlabathi.

Indawo enkulu yomhlaba noma yethusi yamandla nayo ingadlala indima yokuvikelwa, isiza ukunciphisa ukuphazamiseka kwe-electromagnetic, ithuthukise ikhono lokulwa nokuphazamiseka kwesifunda, futhi lihlangabezane nezidingo ze-EMC.

Ngaphezu kwalokho, kumasekethe afudumele aphezulu, indawo ye-Copper inikeza indlela ephelele yokubuyisa amasiginali we-Digital affectuency.

2, ukubeka kwethu ithusi kungathuthukisa amandla okuqeda ukushisa kwe-PCB

Ngaphezu kokunciphisa i-invadance ye-Ground ku-PCB Design, ithusi libuye lisetshenziselwe ukudicilela phansi kokushisa.

Njengoba sonke sazi, i-Metal kulula ukwenza ugesi nokushisa okubonakalayo, ngakho-ke uma i-PCB igcwele ithusi, igebe elisebhodini nezinye izindawo ezingenalutho, ngakho-ke kulula ukuqeda ukushisa kwebhodi le-PCB lilonke.

Ukubeka i-Copper kuyasiza nokusabalalisa ukushisa ngokulinganayo, kuvimbela ukudalwa kwezindawo ezishisayo zasendaweni. Ngokusabalalisa ngokulinganayo ukushisa kuyo yonke ibhodi ye-PCB, ukugxilwa kokushisa kwendawo kungancishiswa, izinga lokushisa lomthombo wokushisa lingancishiswa, futhi ukusebenza kahle kokushisa kokushisa kungathuthukiswa.

Ngakho-ke, ku-PCB Design, ukubeka i-Copper kungasetshenziselwa ukuncipha kokushisa ngalezi zindlela ezilandelayo:

Design Heat Dissipation Areas: Ngokusho kokusatshalaliswa komthombo wokushisa kwi-PCB Board ebhodini lePCB, ukuklama izindawo zokuhlanza ukushisa okunengqondo, bese ubeka i-foil yethusi eyanele kulezi zindawo ukukhulisa indlela yokuhlanza ukushisa kanye nendlela yokuvuselela ukushisa.

Khuphula ubukhulu be-foil ye-Copper

Design Ukuchithwa kokushisa ngokusebenzisa izimbobo: Design Ukuchitheka kokushisa ngokusebenzisa izimbobo endaweni yokuhlanza ukushisa, bese udlulisela ukushisa ngakolunye uhlangothi lwe-PCB Board ngokusebenzisa izimbobo zokunciphisa ukushisa futhi uthuthukise ukusebenza kahle kokushisa.

Faka ukushisa kokushisa: Faka ukushisa kokushisa endaweni yokuhlanza ukushisa, kudlulise ukushisa esikhungweni sokushisa, bese kuthi ukunciphisa ukushisa nge-convection yemvelo noma ukucwilisa ukushisa kokushisa ukuthuthukisa ukusebenza kahle kokushisa.

3, ukubeka kwethu ithusi kunganciphisa ukonakala nokwenza ngcono ikhwalithi yokukhiqiza ye-PCB

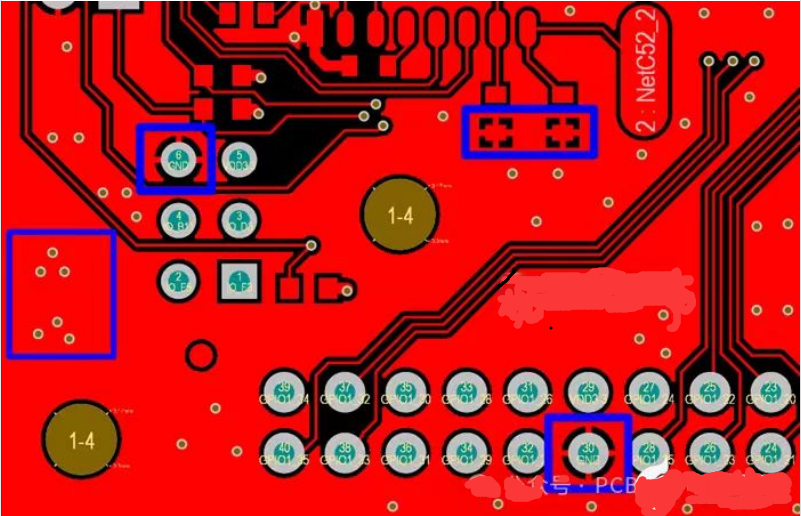

I-Copper Paving ingasiza ekuqinisekiseni ukufana kwe-electroplating, yehlisa i-deformation yepuleti ngesikhathi senqubo yokukhanyiswa, ikakhulukazi i-PCB e-PCB e-Double noma ye-Multi.

Uma ukusatshalaliswa kwe-foil ye-Copper kwezinye izindawo kukhulu kakhulu, futhi ukusatshalaliswa kwezinye izindawo kuncane kakhulu, kuzoholela ekusatshalalisweni okungalingani kwalo lonke ibhodi, futhi ithusi linganciphisa ngempumelelo legebe.

4, ukufeza izidingo zokufaka zamadivayisi akhethekile.

Kwamanye amadivaysi akhethekile, njengamadivayisi adinga izidingo zokufaka noma ezikhethekile, ukubeka ithusi kunganikeza amaphuzu angeziwe okuxhuma kanye nokusekelwa okuhleliwe, ukuthuthukisa ukuqina kanye nokwethembeka kwensiza.

Ngakho-ke, ngokuya ngezinzuzo ezingenhla, ezimweni eziningi, abaqambi bama-elekthronikhi bazobeka ithusi ebhodini le-PCB.

Kodwa-ke, ukubeka ithusi akuyona ingxenye edingekayo ye-PCB design.

Kwezinye izimo, ukubeka kwethu ithusi kungenzeka kungabi nalo noma kungenzeka. Nawa amanye amacala lapho ithusi kufanele lingasatshalaliswa:

A), umugqa wesiginali wemvamisa ophakeme:

Ukuze uthole imigqa yesiginali yemvamisa ephezulu, ukubeka i-Copper kungaletha ama-capacitors angeziwe kanye ne-inductors, okuthinta ukusebenza kokuhambisa kwesiginali. Emibuthanweni ye-light-frequency, kuvame ukudingekile ukulawula imodi ye-wiring yocingo lomhlabathi futhi unciphise indlela yokubuya yocingo lomhlabathi, kunokuba ithusi elibekelwe ngaphezulu.

Isibonelo, ukubeka ithusi kungathinta ingxenye yesiginali ye-antenna. Ukubeka ithusi endaweni ezungeze i-antenna kulula ukudala isibonakaliso esiqoqwe ngesiginali ebuthakathaka ukuthola ukuphazanyiswa okukhulu. Isiginali ye-antenna iqine kakhulu ekuhlelweni kwepharamitha ye-amplifier, futhi ukungasebenzi kokubeka kwethusi kuzothinta ukusebenza komjikelezo we-amplifier. Ngakho-ke indawo ezungeze isigaba se-antenna imvamisa ayimbozwa ithusi.

B), ibhodi yesifunda eliphakeme kakhulu:

Kumabhodi wesifunda eliphakeme kakhulu, ukubekwa kwethusi ngokweqile kungaholela emibukeni emifushane noma izinkinga zomhlaba phakathi kwemigqa, kuthinta ukusebenza okujwayelekile kwesifunda. Lapho uklama amabhodi wesifunda eliphakeme kakhulu, kuyadingeka ukuklama ngokucophelela isakhiwo sethusi ukuqinisekisa ukuthi kukhona isikhala esanele nokufakelwa phakathi kwemigqa ukugwema izinkinga.

C), ukunqamula kokushisa okusheshayo, ubunzima bokushisa:

Uma i-PIN yesakhi isembozwe ngokuphelele ithusi, kungadala ukuhlukaniswa okushisa ngokweqile, okwenza kube nzima ukususa i-welding nokulungisa. Siyazi ukuthi ukuthuthuka okushisayo kwethusi kuphakeme kakhulu, ngakho-ke noma ngabe kuyincwajana ye-welding noma ukukhombisa ukushisa ngokushesha ngesikhathi se-welding, ngakho-ke umklamo we-welding, ngakho-ke umklamo we-welding, uzuze i-delding.

D), izidingo ezikhethekile zemvelo:

Kwezinye izindawo ezikhethekile, njengokushisa okuphezulu, umswakama ophezulu, indawo yokulimazeka, i-foil yethusi ingalimala noma igcwaliswe, ngaleyo ndlela ithinta ukusebenza kwebhodi le-PCB. Kulokhu, kuyadingeka ukuthi ukhethe izinto ezifanele nokwelashwa ngokwezidingo ezithile zemvelo, kunokuba ithusi ngokweqile.

E), izinga elikhethekile lebhodi:

Ibhodi yesekethe eliguquguqukayo, ibhodi elihlanganisiwe eliqinile futhi eliguquguqukayo kanye nezinye izingqimba ezikhethekile zeBhodi, kuyadingeka ukubeka umklamo wethusi ngokuya ngezidingo ezithile kanye nokucaciswa okuhlanganisiwe okubangelwa ukufakwa kwesendlalelo ngokweqile.

Ukufingqa, ku-PCB Design, kuyadingeka ukukhetha phakathi kwe-Copper ne-Non-Copper ngokuya ngezidingo ezithile zokujikeleza, izidingo zemvelo kanye nezimo ezikhethekile zohlelo lokusebenza.