Ngokuvamile: uma kuqhathaniswa nenqubo yokukhiqiza yebhodi le-multi-layer kanye nebhodi le-double-layer, kunezinqubo ezingu-2 ngaphezulu, ngokulandelana: umugqa wangaphakathi kanye ne-lamination.

Ngokuningiliziwe: ekukhiqizeni ipuleti le-double-layer, ngemva kokuqedwa kokusika, ukubhoboza kuzokwenziwa, bese kuba yithusi, umugqa; Enqubweni yokukhiqiza ibhodi le-multi-layer, ngemva kokuvulwa kwezinto ezibonakalayo, ngeke kubhojwe ngokuqondile, kodwa kuqala kudinga ukudlula umugqa wangaphakathi kanye ne-lamination, bese ku-workshop yokubhoboza, bese kuthi-ke. ethusi kanye nomugqa.

Okusho ukuthi, phakathi kwezimbobo zokuvula nokubhoboza, izinqubo ezimbili "zomugqa wangaphakathi" kanye "ne-lamination" zengezwa. Okungenhla umehluko phakathi kwebhodi lezingqimba eziningi kanye nokukhiqizwa kwebhodi elinezingqimba ezimbili.

Okulandelayo, ake sibheke ukuthi izinqubo ezimbili zomugqa wangaphakathi kanye ne-lamination zenzani

Umugqa wangaphakathi

Inqubo "yomugqa" ekukhiqizeni amapuleti aphindwe kabili, okuhlanganisa ukucindezelwa kwefilimu, ukuchayeka, ukuthuthukiswa (uma ukhohlwa, ungabuyela emuva futhi uyibuke).

I-"circuit yangaphakathi" lapha ayilula kangako! Ngaphezu kwefilimu e-laminated yangaphakathi, ukuchayeka kwangaphakathi, ukuthuthukiswa kwangaphakathi, kuhlanganisa nokwelashwa kwangaphakathi kwangaphakathi, ukufakwa kwangaphakathi, ukukhishwa kwefilimu yangaphakathi kanye ne-AOI yangaphakathi.

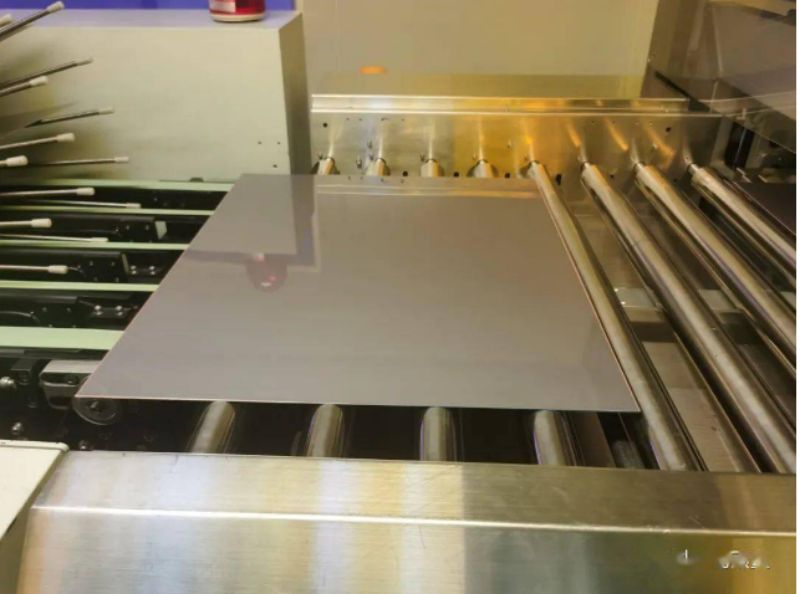

Enkambweni yokukhiqiza ipuleti eliphindwe kabili, ibhodi ngemuva kokuqedwa kokufakwa kwethusi, ngaphandle komugqa wokukhiqiza, ngqo kwifilimu ecindezelayo, ngakho-ke asikho isidingo sokwenza ukwelashwa okwengeziwe kwangaphambi kokucindezela. Futhi ipuleti le-foil yethusi lapha, lisanda kuvela endaweni yokusebenzela yokusika, ingaphezulu lebhodi lizoba nokungcola, ngakho-ke.

Ngaphambi kwefilimu yangaphakathi ye-laminate, kuyadingeka ukuqhubekisela phambili ukwelashwa nokuhlanza, ukusetshenziswa kokusabela kwamakhemikhali, kuqala ukususa amafutha, amanzi, amanzi ahlanzekile, ama-micro-etching amabili (susa udoti ongaphezulu), bese amanzi, bese u-picling (ngemuva ukugeza, ubuso buzobe bufakwe oxidized, ngakho-ke budinga ukuchotshozwa), bese amanzi, bese omile, bese efaka ifilimu yangaphakathi ye-laminate.

Ifilimu ye-laminate yangaphakathi ngaphambi kokwelashwa

Ngemva kokucindezela ibhodi, ngenxa yokuthi alizange liboshwe, libukeka liphansi kakhulu.

Ifilimu ecindezelayo, ukuchayeka, ukuthuthukiswa, izindaba ezithile zalezi zixhumanisi, zethulwe esihlokweni sokukhiqizwa kwamapuleti aphindwe kabili, lapha ngeke kuphindwe.

Ngemva kokuqedwa kokuthuthukiswa, ingxenye yethusi izovezwa, ngoba ungqimba lwangaphandle luyinqubo yefilimu enhle, ungqimba lwangaphakathi luyinqubo yefilimu engalungile. Ngakho-ke, ngemva kokuqedwa kokuthuthukiswa koqweqwe lwangaphandle, umugqa wethusi oveziwe yingxenye edinga ukugcinwa, futhi ithusi elivezwe ngemva kokuthuthukiswa kongqimba lwangaphakathi liyingxenye edinga ukucishwa, ngakho-ke.

Inqubo ye-inner etching kanye nenqubo yokudonsa yangaphandle nayo ihlukile, ukufakwa kwangaphakathi kuyinqubo ye-alkaline, ngesikhathi sokuqopha, ifilimu eyomile isekhona, ingxenye ngaphandle kwefilimu eyomile (ithusi eliveziwe) iqoshwa kuqala, futhi bese kususwa isikhunta.

Ukuqoshwa koqweqwe lwangaphandle kuqala kukhishwa bese kuqoshwa, futhi umugqa uvikelwe ngokwengxenye yithini eliwuketshezi.

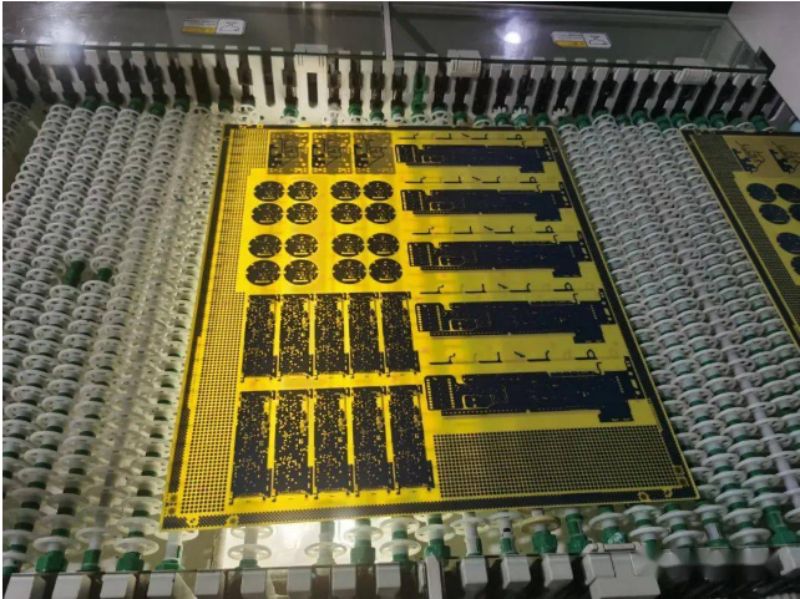

Umugqa wokuqopha ifilimu wangaphakathi, kwesokunxele unesibopho sokuqopha, kwesokudla kunesibopho sokuhoxiswa kwefilimu.

Ngemuva kokunamathisela ibhodi lesifunda, ithusi eliningi likhishwe, futhi ingxenye esele yefilimu eyomile ayizange isuswe.

Ibhodi lesifunda ngemva kokukhumula.

Ngemuva kokuthi ungqimba lwangaphakathi lwefilimu luqediwe, ungqimba lwangaphakathi lomugqa lwenziwe ngokuphelele, ngalesi sikhathi, bese kuba ukutholwa kwe-AOI optical, ukuze kutholakale ukuthi ayikho inkinga, ungenza inqubo yokugcoba.

I-Lamination:

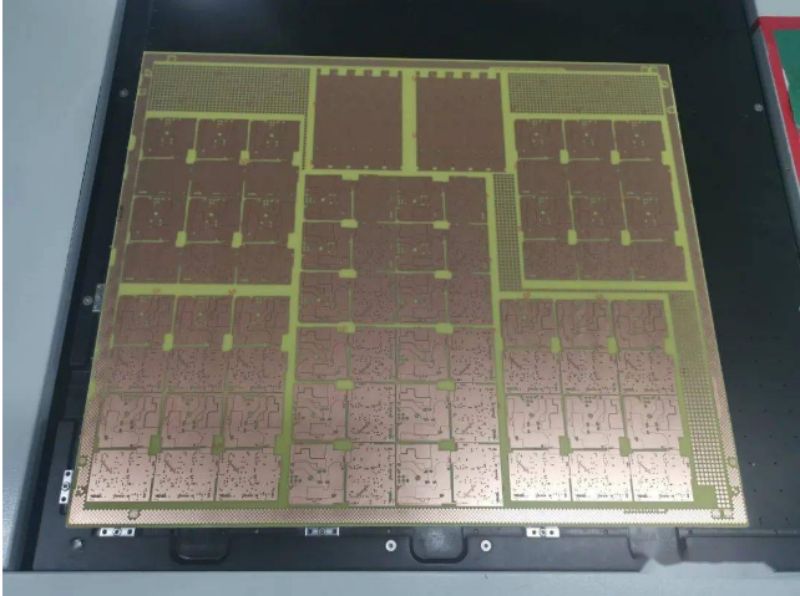

Usanda kwenza ibhodi, siyibiza ngokuthi ibhodi elingaphakathi elingaphakathi, uma liyizingqimba ezi-4 zebhodi, kuzoba nebhodi elingaphakathi eli-1, uma liyizingqimba ezi-6 zebhodi, kuzoba namabhodi angu-2 angaphakathi.

Inhloso eyinhloko yale nqubo ukwenza i-inner core plate kanye nesendlalelo sangaphandle sihlanganiswe ukuze sakhe sonke. Ibhekele izinto ezibophayo, ezibizwa nge-PP, isiShayina esibizwa nge-semi-curing sheet, ukwakheka okuyinhloko i-resin ne-glass fiber, izophinde idlale ibhodi elingaphakathi eliwumgogodla kanye nenhloso yokufakwa kwe-foil yethusi yangaphandle.

Ukuze kuqinisekiswe ikhwalithi yebhodi enezingqimba eziningi, umphakeli we-PP wase-Jialichuang useyi-South Asia Electronics.

Ngokuvamile, inqubo yokugcoba ihlukaniswe ngezinyathelo ezine ngokulandelana: I-Browning, i-pre-stacking, i-platen, nokucindezela. Okulandelayo, ake sibheke imininingwane yenqubo ngayinye ngokwehlukana.I-inner core plate ngemva kokuqedwa kokususwa kwefilimu iba nsundu kuqala. Ibhodi lesifunda elinsundu lizokwengeza ungqimba lwefilimu enombala onsundu ebusweni bebhodi lesifunda, okuyizinto ezisansimbi ensundu, futhi ubuso bayo bungalingani, ukuze kube lula ukuhlangana ne-PP.

Isimiso sifana nalapho kulungiswa isondo lebhayisikili, indawo ephukile kufanele ifakwe ngefayela ukuze kuthuthukiswe ukunamathela kweglue.

Inqubo ye-Browning iphinde ibe inqubo yokusabela kwamakhemikhali, ezodlula ekukhetheni, ukuwasha nge-alkali, ukuwasha ngamashaneli amaningi, ukomiswa, ukupholisa nezinye izinqubo.

prelap

Inqubo yokupakisha ngaphambilini, eyenziwa endaweni yokusebenzela engenazo izintuli, izobeka ipuleti eliwumgogodla kanye ne-PP ndawonye. I-PP ibekwe ohlangothini ngalunye lwe-core plate. Ubude nobubanzi be-PP buzoba bukhulu ngo-2mm kune-core plate ukuze kuvinjwe imiphetho engenalutho ngemva kokucindezela.

I-raft:

Inhloso eyinhloko yepuleti yomugqa ukwengeza ungqimba lwe-foil yethusi ngaphezu kwesendlalelo se-PP ukulungiselela umugqa wangaphandle olandelayo. Ngaphezu kwalokho, ipuleti lensimbi kanye nephepha le-kraft lizokwengezwa kungqimba olungaphandle.lamination

Izinyathelo zokuqala ezimbalwa ziwukulungiselela i-lamination yokugcina.

Ngaphambi kwe-laminating, ukuze kuvinjwe ukungqubuzana, kuzoba nepuleti lekhava, eliwugqinsi elingu-12mm, insimbi.

I-Laminating ihlanganisa izinqubo ezimbili zokucindezela okushisayo nokucindezela okubandayo, ngokulandelanayo kumshini wokushisa oshisayo nokucindezela okubandayo. Lesi isixhumanisi esibaluleke kakhulu, ukucabangela izici ezihlanganisa i-vacuum, izinga lokushisa, ingcindezi, isikhathi, lezi zici zisebenzisana nomunye nomunye, ukuze kukhiqizwe amabhodi wesifunda aphezulu.

Ngokwesibonelo, esikhathini esithile, izinga lokushisa elingakanani, ingcindezi engakanani, nobude besikhathi obudingekayo, kufanele kulungiswe ngokunembile.

Ngemuva kokuphela kwale nqubo, i-PP kanye ne-inner core plate kanye ne-foil yethusi yangaphandle izoxhunyaniswa eduze.

Ngemva kokuphuma emshinini wokunyathelisa, ukuhlakazwa okuzenzakalelayo kuyenziwa, ipuleti lensimbi liyasuswa, bese lithunyelwa ekamelweni le-platoon futhi ngemva kokugaya. Njengoba kuboniswe kuMfanekiso 11, umshini ususa ipuleti lensimbi.

Ibhodi lesifunda elinezingqimba eziningi elaminethiwe lizobuyiselwa endaweni yalo yokuqala yokumba ukuze libhojwe, futhi yonke enye inqubo iyafana nenqubo yokukhiqiza yebhodi elinezingqimba ezimbili.