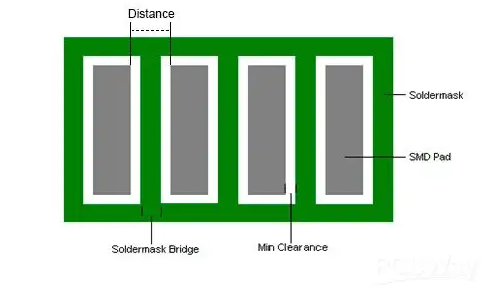

Ngaphambi kokwethula iwindi lemaski ye-solder, kufanele siqale sazi ukuthi iyini imaski ye-solder. Imaski ye-solder isho ingxenye yebhodi lesekethe ephrintiwe ezofakwa u-inki, esetshenziselwa ukumboza iminonjana nethusi ukuvikela izakhi zensimbi ku-PCB futhi kuvinjwe amasekhethi amafushane. Ukuvula imaski ye-solder kubhekisela ekuvuleni imbobo kungqimba lwemaski ye-solder ukuze ukushisela kwenziwe lapho kuvulwa. Noma iyiphi indawo lapho ingekho imaski ye-solder ephrintiwe ingabizwa ngokuvula iwindi. Indawo lapho imaski ye-solder ingaphrintiwe ihlanganisa amaphedi athengiswayo, ama-patch pads, izikhundla ze-slot, njalonjalo. Kukhona necala elibizwa ngefasitela elivulekile. Iwindi elivulekile isigamu lisho ukuthi ingxenye ye-pad ayimbozwanga nge-solder mask, kanti enye imbozwe nge-solder mask.

一. Ungahlukanisa kanjani "ngefasitela" kanye "ngamafutha ekhava"

Amagama "ngefasitela" kanye "nge-cap oil" angase azwakale kaningi ekwakhiweni kwebhodi lesifunda. Eqinisweni, ngokwezwi nezwi kusho ukuthi omunye uvula ifasitela embobeni, kanti omunye uvala imbobo ngamafutha. Ngamanye amazwi, noma ngabe i-insulate ebusweni be-PCB..

Evula iwindikusho ukuthi ikwazi ukunamathiselwa kalula endaweni lapho iwindi livulwa khona, futhi ukuthi iwindi lingavuleka yini kungahlulelwa ngokuthi lingafakwa yini. Amafutha ekhava abhekisela eqinisweni lokuthi akulula ukuthayela ngesikhathi se-patch, okunqunywa inqubo. Izizathu zokuthi kungani i-vias inomuzwa wokuthi ayimboziwe ngamafutha yilezi ezilandelayo: ngoba amafutha e-mask e-solder ayiketshezi futhi phakathi kwezimbobo azinalutho, kulula ukuthi uwoyela ungene ngezimbobo ngesikhathi sokubhaka. amafutha e-mask e-solder e-solder mask ring. Ngenxa yalokho, ukuphuzi kwe-vias kwenzeka. Lesi simo sihlobene nokuhlushwa kwe-solder ukumelana namafutha, ihhavini namandla, ngakho-ke kuyoba khona izimo lapho okuluhlaza kungavela khona, kuyilapho abanye bengakwazi.

二.Kungani sidinga ukuvula iwindi lemaski ye-solder?

Nge-vias, uma iwindi lingavulwa, inki ye-solder mask izongena emgodini. Kwezinye izimbobo ezingadingi izimbobo zepulaki kayinki, kuyadingeka ukuziklama njengezimbobo. Ngezingxenye ezifakwe emgodini, uma i-PCB ingathengiswa ukuvula iwindi, izingxenye azikwazi ukuthengiswa ebhodini ngokujwayelekile. Ukuvulwa kwembobo akuwona nje umsebenzi wokushisela okulula, kodwa futhi kungalinganiswa nge-vias. Ukuvuleka kwemaski ye-Solder yezimbobo kwezinye izindawo ezikhethekile kungasetshenziswa ukukala i-vias nge-multimeter..

Ku-PCB, uma iwindi lingavulwanga, ukwelashwa okungaphezulu akukwazi ukwenziwa, futhi akukho ukufutha ngethini noma ukushisela okungenziwa.

三.Ungalivula kanjani iwindi lemaski ye-solder?

1. Ekuklanyeni, i-pad izovula iwindi ngokuzenzakalelayo (OVERRIDE: 0.1016mm), okungukuthi, i-pad ivezwe ku-foil yethusi, futhi ukunwetshwa kwangaphandle kungu-0.1016mm, futhi i-wave soldering ifakwe. Izinguquko zedizayini azinconywa ukuze kuqinisekiswe ukuthengiselana

2. Ngokuzenzakalela, i- via hole izoba nefasitela (OVERRIDE: 0.1016mm) ekwakhiweni, okungukuthi, i- via hole ivezwa kucwecwe lwethusi, ukunwetshwa kwangaphandle kungu-0.1016mm, futhi ithini lizosetshenziswa ngesikhathi sokufakwa kwamagagasi. Uma idizayini iwukuvikela i-vias ukuthi ithinini futhi ingavezi ithusi, inketho ye-PENTING kumele ibhekwe ezindaweni ezengeziwe ze-SOLDER MASK ukuze kuvalwe ukudlula.

3. Ngaphezu kwalokho, lesi singqimba singasetshenziselwa izintambo ezingezona zikagesi zodwa, futhi i-solder mask amafutha aluhlaza izovula iwindi ngokufanele. Uma isendaweni ye-copper foil trace, isetshenziselwa ukuthuthukisa ikhono elidlulele le-trace, futhi ingafakwa ithini lapho i-soldering. Uma iku-trace ye-foil engeyona eyethusi, ngokuvamile iklanyelwe ukuphrinta isikrini sikasilika samalogo nezinhlamvu ezikhethekile, ezingasindisa ukukhiqizwa.