I-1.copper Cladding

Ukubizwa okubizwa ngokuthi yi-Copper Coating, kuyisikhala esiyize ebhodini lesekethe njenge-dum, bese kugcwala ithusi eliqinile, lezi zindawo zethusi zaziwa nangokugcwaliswa kwethusi.

Ukubaluleka kwe-Coating Coating yile: Yehlisa amandla aphansi, ukwenza ngcono ikhono lokulwa nokuphazamiseka; Yehlisa i-Voltage Drop, ngcono ukusebenza kahle kwamandla; Ixhunywe ngocingo lomhlabathi, inganciphisa nendawo ye-loop.

Futhi ngenhloso yokwenza i-PCB Welding njenge-deformation ngangokunokwenzeka, iningi labakhiqizi be-PCB lizodinga futhi abaklami be-PCB ukugcwalisa indawo evulekile ye-PCB noma nge-wire yomhlaba wethusi noma yegridi. Uma ithusi lingaphendulwanga kahle, lizoba ngaphezu kokufanele ukulahleka. Ukuthi ithusi "lihle kakhulu kunokubi" noma "kubi kakhulu kunokuhle"? Njengoba sonke sazi, esimweni semvamisa ephezulu, ukuhanjiswa okusatshalaliswa kwe-wiring ebhodini lesekethe eliphrintiwe kuzosebenza. Lapho ubude bukhulu kune-1/20 ye-wavenvength ehambelana nemvamisa yomsindo, kuzokhiqizwa umphumela we-antenna, futhi umsindo uzokhishwa ngaphandle nge-wiring. Uma kukhona ukugcotshwa kwethusi okusekelwe kabi kwi-PCB, ukuhlanganiswa kwethusi kuzoba yithuluzi lokusakaza umsindo.

Ngakho-ke, esisekelweni semvamisa ephezulu, ungacabangi ukuthi umhlabathi ndawo ndawo, lena "yintambo yomhlaba", kufanele ube ngaphansi kwesikhala se-λ / 20, endizeni emgodini we-multilayer "isisekelo esihle". Uma i-Copper Coating yelashwa kahle, ukuhlanganiswa kwethusi akugcini nje ngokukhulisa okwamanje, kodwa futhi kudlala indima embaxambili yokuphazamiseka. Ngakho-ke, esisekelweni semvamisa ephezulu, ungacabangi ukuthi umhlabathi ndawo ndawo, lena "yintambo yomhlaba", kufanele ube ngaphansi kwesikhala se-λ / 20, endizeni emgodini we-multilayer "isisekelo esihle". Uma i-Copper Coating yelashwa kahle, ukuhlanganiswa kwethusi akugcini nje ngokukhulisa okwamanje, kodwa futhi kudlala indima embaxambili yokuphazamiseka.

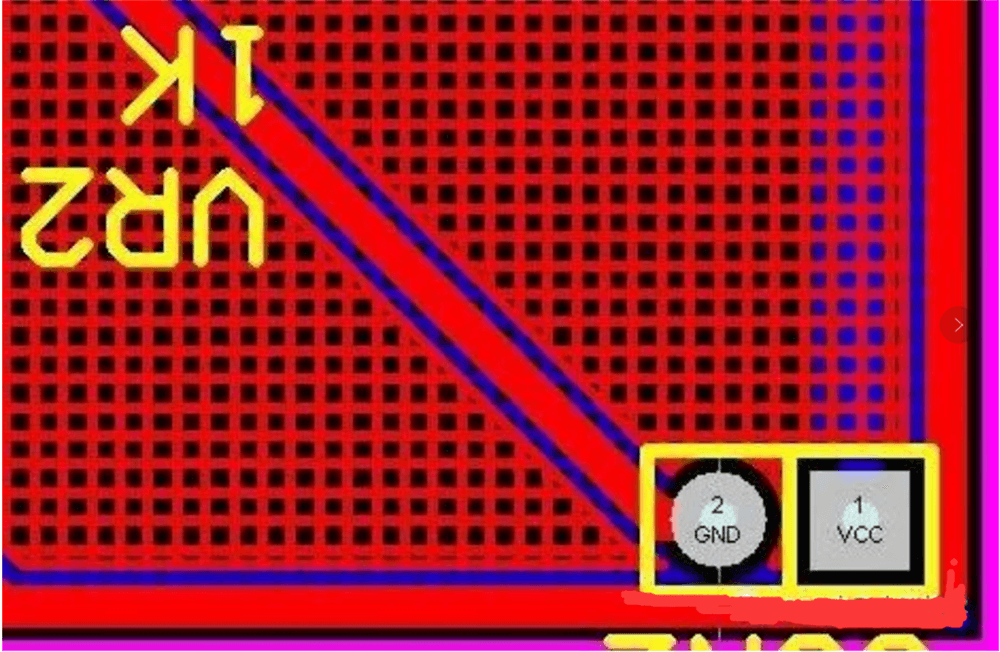

2.two izinhlobo ze-copper coating

Kunezindlela ezimbili eziyisisekelo zokumboza ithusi, okungukuthi, indawo enkulu yethusi ne-grid yethusi yethusi, kuvame ukubuzwa ukuthi indawo enkulu yethusi noma iGridi yethusi yinhle.

Ngani? Indawo enkulu ye-Coating Coating, ngokwandisa iqhaza eliphambili lamanje nokuvikela, kepha indawo enkulu yama-coating ethuni, uma igagasi le-wavel soldeling, ibhodi lingavutha, noma i-bubble. Ngakho-ke, indawo enkulu yethusi imbozwe, futhi izikhala eziningana zivulwa ngokuvamile ukuqeda amagwebu we-foil we-Copper.

Igridi elula embozwe yi-Copper ikhafulela ngokukhethekile, indima yokwandisa okwamanje iyancishiswa, ukusuka endaweni yokubukwa kokushibilika kokushisa, i-grid inezinzuzo zethusi) futhi idlala indima ethile yokuvikelwa kwe-electromagnetic. Ikakhulu ekulandeleni umjikelezo, njengoba kukhonjisiwe kwisibalo esingezansi: Kuyadingeka ukuveza ukuthi igridi yakhiwa imigqa emile. Siyazi ukuthi ngokujikeleza, ububanzi bemigqa bunezinto ezihambisanayo "ezihambelana nalo imvamisa yokusebenza kwebhodi yokujikeleza (ubukhulu bangempela bungahlukaniswa yimvamisa yedijithali ehambelana nemvamisa esebenzayo, bheka izincwadi ezifanele).

Lapho imvamisa yokusebenza ingaphezulu kakhulu, mhlawumbe imigqa yegridi ayilusizo kakhulu, futhi uma ubude bagesi befanisa imvamisa yokusebenza, kubi kakhulu, futhi uthola ukuthi umjikelezo awusebenzi kahle, futhi kukhona amasiko yonke indawo ephazamisa kahle uhlelo.

Isiphakamiso ukukhetha ngokuya ngokwakhiwa kwebhodi yesekethe, hhayi ukubambelela entweni. Ngakho-ke, umjikelezo wemvamisa ophakeme wokulwa nezidingo zokuphazamiseka zegridi enamahlosi amaningi, umjikelezo ophansi wemvamisa onomjikelezo omkhulu wamanje nangomunye umjikelezo omkhulu osetshenzisiwe.