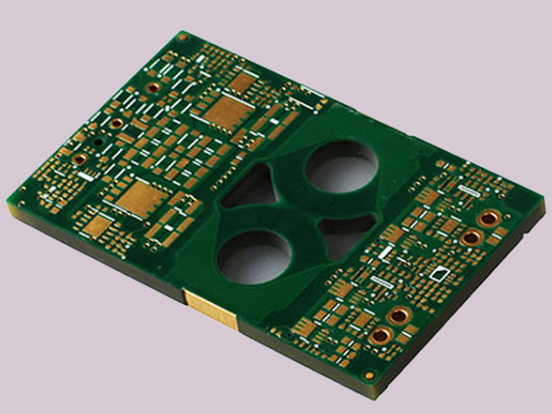

Ukwethulwa kweIbhodi elibanzi le-Copper ComputerUbuchwepheshe

(1) Ukulungiselela Pre-Plating Pre-Plating and Electroplating Treatment

Inhloso enkulu yokuqina ithusi Plating ukuqinisekisa ukuthi kukhona ungqimba olunamanzi olwanele olwanele emgodini ukuqinisekisa ukuthi inani lokumelana lingaphakathi kwebanga elidingekayo inqubo. Njenge-plug-in, ukulungisa isikhundla futhi uqinisekise amandla okuxhuma; Njengethuluzi elifakwe endaweni elingaphezulu, ezinye izimbobo zisetshenziswa kuphela ngokusebenzisa izimbobo, ezidlala indima yokwenza ugesi ezinhlangothini zombili.

(2) Izinto Zokuhlola

1. Kakhulu hlola ikhwalithi yensimbi yomgodi, futhi uqinisekise ukuthi akukho okweqile, burr, umgodi omnyama, umgodi, njll emgodini;

2. Bheka ukuthi ngabe kukhona ukungcola nokunye okweqile ebusweni be-substrate;

3. Bheka inombolo, inombolo yokudweba, idokhumenti lenqubo kanye nencazelo yenqubo ye-substrate;

4. Thola isikhundla esikhuphukayo, izidingo ezikhuphukayo kanye nendawo yokuhlangana ethangi lokuthwebula.

5

6. Ukuhlanza nokulungiswa kwezingxenye ezisebenzayo, ukwelashwa kukagesi kuqala ukwenza ikhambi lisebenze;

7. Nquma ukuthi ukwakheka koketshezi lokugeza kuyafaneleka futhi indawo engaphezulu yepuleti ye-electrode; Uma i-anode eyindilinga ifakwa kwikholamu, ukusetshenziswa kumele futhi kuhlolwe;

8. Bheka ukuqina kwezingxenye zokuxhumana kanye nohla lokuguquguquka lwamandla kagesi nawamanje.

(3) Ukulawulwa kwekhwalithi ye-PREPT PREPT

1

2. Ngaphambi kwe-electroplating, okokuqala sebenzisa ibhodi le-debugging ukuze ibhavu lisesimweni esisebenzayo;

3. Thola ukuqondiswa kokugeleza kwenani lamanje, bese unquma ukuhleleka kwamapuleti alengise. Ngokuyinhloko, kufanele isetshenziswe kusuka kude ukuyoseduze; ukuqinisekisa ukufana kokusatshalaliswa kwamanje kunoma iyiphi indawo;

I-4. Ukuqinisekisa ukufana kokuhlanganiswa emgodini kanye nokuvumelana kokuqina kokuhlanganiswa, ngaphezu kwezindlela zobuchwepheshe zokuvusa nokuhlunga, kuyadingeka ukusebenzisa okuphoqayo kwamanje;

5. Bheka njalo izinguquko zamanje kwinqubo ye-electroplating ukuze uqinisekise ukuthembeka nokuqina kwenani lamanje;

6. Bheka ukuthi ubukhulu besendlalelo se-post plating of the hole lihlangabezana nezidingo zobuchwepheshe.

(4) Inqubo yokuqothula yethusi

Enqubweni yokuqina ithusi Plating, amapharamitha enqubo kumele aganwe njalo, futhi ukulahleka okungadingekile kuvame ukubangelwa ngenxa yezizathu ezibonakalayo nezinhloso. Ukuze wenze umsebenzi omuhle wokuqina inqubo yokuhlela ithusi, lezi zici ezilandelayo kufanele zenziwe:

1. Ngokusho kwenani lendawo elibalwe yikhompyutha, elihlanganiswe nesipiliyoni esinqunyelwe ukukhiqizwa kwangempela, kwandise inani elithile;

2

3. Lapho i-electroplation yebhodi yesekethe ifinyelela emizuzwini emi-5, khipha i-substrate ukuthi ngabe ungqimba lwethusi ebusweni nodonga lwangaphakathi lomgodi luqediwe, futhi kungcono ukuthi zonke izimbobo zibe ne-luster yensimbi;

I-4. Ibanga elithile kufanele ligcinwe phakathi kwe-substrate kanye ne-substrate;

I-5. Lapho i-Plave Plating ethubeni elicijile ifinyelela isikhathi esidingekayo se-electroplating, inani elithile lamanje kufanele ligcinwe ngesikhathi sokususwa kwe-substrate ukuqinisekisa ukuthi ingaphezulu nezimbobo ze-substrate ezalandela ngeke zibe mnyama noma zimnyama.

Izinyathelo zokuzivikela:

1. Bheka amadokhumenti enqubo, funda izidingo zenqubo futhi ujwayelene nemishini emishini ye-substrate;

2

3. Yenza ukucutshungulwa kwecala ngokuya nge-mechanical processing disk, yenza ukuhlolwa kokuqala kokuqala, bese ucubungula yonke imisebenzi ngemuva kokuhlangabezana nezidingo zobuchwepheshe;

4. Lungiselela amathuluzi okulinganisa namanye amathuluzi asetshenziselwa ukuqapha ubukhulu bejometri ye-substrate;

I-5

(5) Ukulawulwa kwekhwalithi

1. Sebenzisa ngokuqinile uhlelo lokuhlola i-athikili yokuqala ukuze uqinisekise ukuthi usayizi womkhiqizo uhlangabezana nezidingo zokuklama;

2. Ngokuya ngezinto ezingavuthiwe zebhodi yesekethe, khetha kahle amapharamitha enqubo yokugaya;

3. Lapho ulungisa isikhundla sebhodi yesekethe, ngivimbele ngokucophelela ukugwema ukulimala ku-solder ungqimba kanye imaski ye-solder ebusweni bebhodi yesekethe;

I-4. Ukuqinisekisa ukuvumelana kobukhulu bangaphandle be-substrate, ukunemba kwesikhashana kufanele kulawulwe ngokuqinile;

5