Ukucutshungulwa kwe-SMTuchungechunge lwezobuchwepheshe bezinqubo zokucubungula ngesisekelo se-PCB. Inezinzuzo zokunemba okuphezulu okuphezulu nejubane elisheshayo, ngakho-ke yamukelwe ngabakhiqizi abaningi be-elekthronikhi. Inqubo yokucubungula i-SMT Chip ikakhulukazi ifaka isikrini kasilika noma ukusatshalaliswa kwe-glue, ikhwela, ukukhombisa ukuthengisa, ukuhambisa, ukuhlola, izinqubo eziningi zenziwa ngendlela ehlelekile ukuqedela yonke inqubo yokuhleleka.

1.Screen ukuphrinta

Imishini yangaphambili ephelele etholakala emugqeni wokukhiqiza iSMT ngumshini wokuphrinta wesikrini, umsebenzi wawo wokuphrinta ukuphrinta noma i-glue othengisa i-plune noma i-patch glue emaphepheni we-PCB ukulungiselela ukuthengisa izingxenye.

2. Ukusabalalisa

Imishini etholakala ekugcineni komugqa wokukhiqiza i-SMT noma ngemuva komshini wokuhlola yindawo ye-glue dispenser. Umsebenzi wayo oyinhloko ukulahla i-glue esimweni esinqunyelwe se-PCB, futhi inhloso ukulungisa izakhi kwi-PCB.

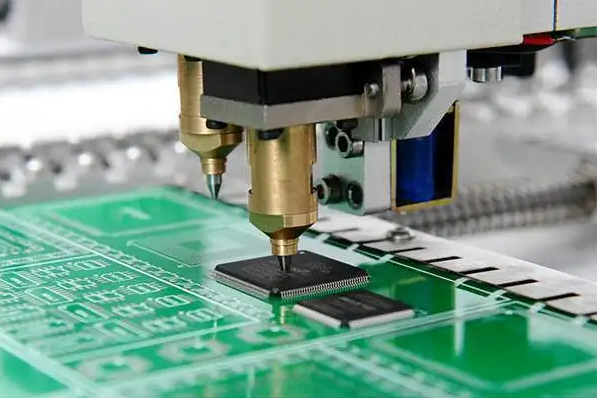

3. Ukubekwa

Imishini ngemuva komshini wokuphrinta wesikrini kasilika emugqeni wokukhiqiza iSMT ngumshini wokubekwa, okusetshenziselwa ukuthwala kahle izingxenye ze-support ntamu endaweni ehleliwe kwi-PCB.

4. Ukwelapha

Imishini ngemuva komshini wokubekwa emugqeni wokukhiqiza i-SMT iyisithako sokwelapha, umsebenzi wawo oyisisekelo ukuncibilikisa i-glue ebekiwe, ukuze izingxenye ze-PCB ziboshwe ngokuqinile.

5. Thumela ukuthengisa

Imishini ngemuva komshini wokubekwa emugqeni wokukhiqiza i-SMT i-oveni ye-SMT iveza kuhhavini, omsebenzi wayo oyinhloko ukuncibilikisa ukunamathisela okuthengiswayo ukuze izingxenye ze-PCB ze-PCB ziboshwe ngokuqinile ndawonye.

6. Ukutholwa

Ukuze uqinisekise ukuthi ikhwalithi ye-soldering kanye nomhlangano webhodi elihlanganisiwe lePCB lihlangana nezidingo zefekthri, izibuko ezikhulisayo, ama-microscopes, ukuhlolwa kwesekethe (aooi), ukuhlolwa kokuhlola okuzenzakalelayo neminye imishini. Umsebenzi oyinhloko ukuthola ukuthi iBhodi lePCB linezinkinga ezifana nokuthengisa okubonakalayo, ukuthengisa okungekho, kanye nemifantu.

7. Ukuhlanza

Kungahle kube nezinsalela zokudambisa okulimazayo emzimbeni womuntu onjenge-flux ebhodini elihlanganisiwe lePCB, okudingeka kuhlanzwe ngomshini wokuhlanza.