Ku-welding yebhodi lesifunda elinezingqimba ezimbili, kulula ukuba nenkinga yokunamathela noma i-welding ebonakalayo. Futhi ngenxa yokwanda kwezingxenye zebhodi lesifunda elinezingqimba ezimbili, uhlobo ngalunye lwezingxenye zezidingo ze-welding zokushisela izinga lokushisa nokunye akufani, okuholela ekwandeni kobunzima bokushisela ibhodi lesifunda le-dual-layer, kuhlanganise ne-welding order. kweminye imikhiqizo inezidingo eziqinile.

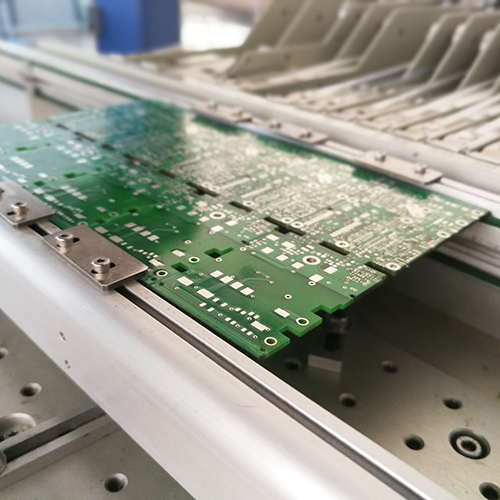

Inqubo yokushisela ibhodi lesifunda elinezinhlangothi ezimbili:

Lungiselela amathuluzi nezinto zokwakha, okuhlanganisa amabhodi wesifunda, izingxenye, i-solder, i-solder paste, ne-solder iron.

Hlanza ingaphezulu lebhodi nezikhonkwane zengxenye: Hlanza ingaphezulu lebhodi nezikhonkwane zengxenye ngesihlanzi noma utshwala ukuze uqinisekise ikhwalithi yokushisela nokwethembeka.

Izingxenye zendawo: Beka izingxenye ebhodini lesifunda ngokuvumelana nezidingo zokuklama zebhodi lesifunda, unake isiqondiso kanye nesimo sezingxenye.

Faka i-solder paste: Faka i-solder pad kumaphini wengxenye kanye nebhodi lesifunda ukulungiselela ukushisela.

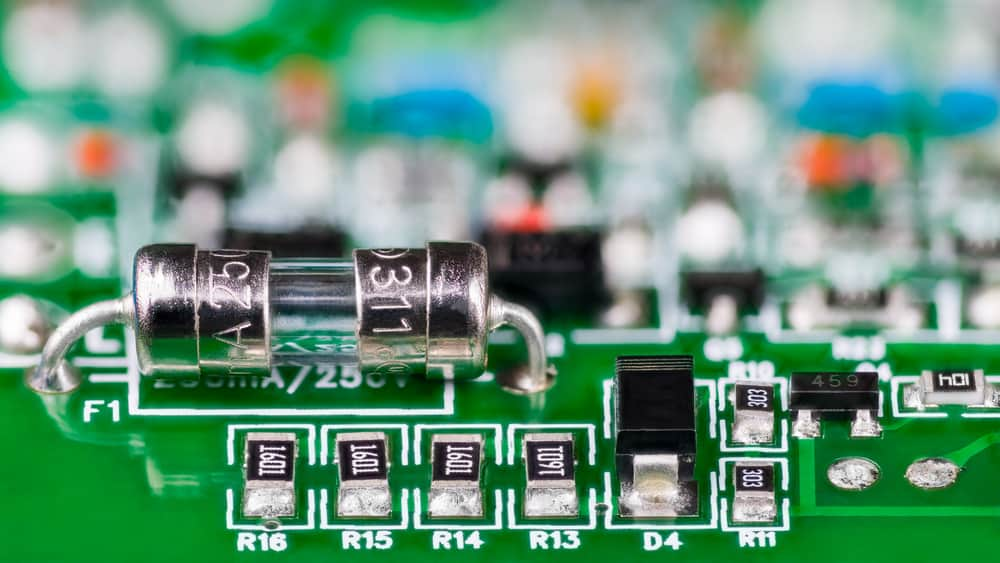

Izingxenye zokushisela: Sebenzisa i-iron soldering kagesi ukuze ushise izingxenye, qaphela ukugcina izinga lokushisa elizinzile nesikhathi, gwema ukushisa ngokweqile noma isikhathi sokushisela side kakhulu.

Hlola izinga lokushisela: hlola ukuthi iphoyinti lokushisela liqinile futhi ligcwele yini, futhi akukho ukushisela okubonakalayo, ukuvuza kwe-welding nezinye izenzakalo.

Ukulungisa noma ukufakwa kabusha: Kumaphoyinti okushisela aneziphambeko zokushisela, ukulungiswa noma ukufakwa kabusha kuyadingeka ukuze kuqinisekiswe izinga lokushisela nokwethembeka.

Ithiphu 1 yokushisela ibhodi lesifunda:

Inqubo yokufaka i-welding ekhethiwe ihlanganisa: ukufafaza kwe-flux, ukushisa kwebhodi lesifunda, i-dip welding kanye nokuhudula i-welding. Inqubo yokugqoka i-Flux Inqubo yokugqoka i-flux idlala indima ebalulekile ekushiseni okukhethiwe.

Ekupheleni kokushisa kwe-welding kanye ne-welding, i-flux kufanele isebenze ngokwanele ukuvimbela ukukhiqizwa kwamabhuloho nokuvimbela i-oxidation yebhodi lesifunda. Ukufafaza kwe-Flux Ibhodi lithwalwa yi-X/Y manipulator phezu kombhobho we-flux, futhi i-flux ifafazwe endaweni yokushisela ibhodi le-pcb.

Ithiphu 2 yokushisela ibhodi lesifunda:

Ukuze uthole ukushisela okukhethekile kwe-microwave ngemva kwenqubo yokuphinda kufakwe i-solder, kubalulekile ukuthi i-flux ifuthwe ngokunembile futhi uhlobo lwesifutho se-microporous ngeke lungcolise indawo engaphandle kwejoyinti le-solder.

Ububanzi bendawo be-micro-spot spraying flux bukhulu kuno-2mm, ngakho-ke ukunemba kwesikhundla se-flux efakwe ebhodini lesifunda ± 0.5mm, ukuze kuqinisekiswe ukuthi ukugeleza kuhlale kumbozwe engxenyeni yokushisela.

Ithiphu 3 yokushisela ibhodi lesifunda:

Izici zenqubo ye-welding ekhethiwe zingaqondwa ngokuqhathanisa ne-wave soldering, umehluko osobala phakathi kokubili ukuthi ingxenye engezansi yebhodi lesifunda ekushiseni kwe-wave igxiliswa ngokuphelele ku-solder liquid, kuyilapho i-welding ekhethiwe, kuphela izindawo ezithile ezithile. baxhumene ne-solder wave.

Njengoba ibhodi lesifunda ngokwalo liyi-medium embi yokudlulisa ukushisa, ngeke lishise futhi lincibilikise amalunga e-solder endaweni eseduze nezingxenye kanye nebhodi lesifunda lapho i-welding.

I-flux kufanele futhi ifakwe ngaphambili ngaphambi kokushisela, futhi uma iqhathaniswa ne-wave soldering, i-flux iboshwe kuphela engxenyeni engezansi yebhodi ukuze ishiselwe, kunebhodi le-pcb yonke.

Ngaphezu kwalokho, i-welding ekhethiwe isebenza kuphela ekushiseni kwezingxenye ze-plug-in, i-welding ekhethiwe iyindlela entsha, futhi ukuqonda okuphelele kwenqubo ekhethiwe yokufaka i-welding kanye nemishini kuyadingeka ekushiseni okuphumelelayo.

Ukushisela ibhodi lesifunda esinezinhlangothi ezimbili kudinga ukwenziwa ngokuhambisana nezinyathelo zokusebenza ezishiwo, qaphela ukuphepha nokulawulwa kwekhwalithi, futhi uqinisekise izinga lokushisela nokuthembeka.

Ukushisela ibhodi lesifunda esinezinhlangothi ezimbili kudinga ukunaka lezi zinto ezilandelayo:

Ngaphambi kokushisela, hlanza indawo yebhodi lesifunda kanye nezikhonkwane zengxenye ukuze uqinisekise ikhwalithi yokushisela nokwethembeka.

Ngokwezidingo zokuklama zebhodi lesifunda, khetha amathuluzi okushisela afanelekile nezinto zokwakha, njenge-solder, i-solder paste, njll.

Ngaphambi kokushisela, thatha izinyathelo ze-ESD, njengokugqoka izindandatho ze-ESD, ukuvikela ukulimala kwe-electrostatic ezingxenyeni.

Gcina izinga lokushisa elizinzile kanye nesikhathi ngesikhathi senqubo yokushisela ukuze ugweme ukushisa ngokweqile noma isikhathi eside kakhulu sokushisa, ukuze ungalimazi ibhodi lesifunda noma izingxenye.

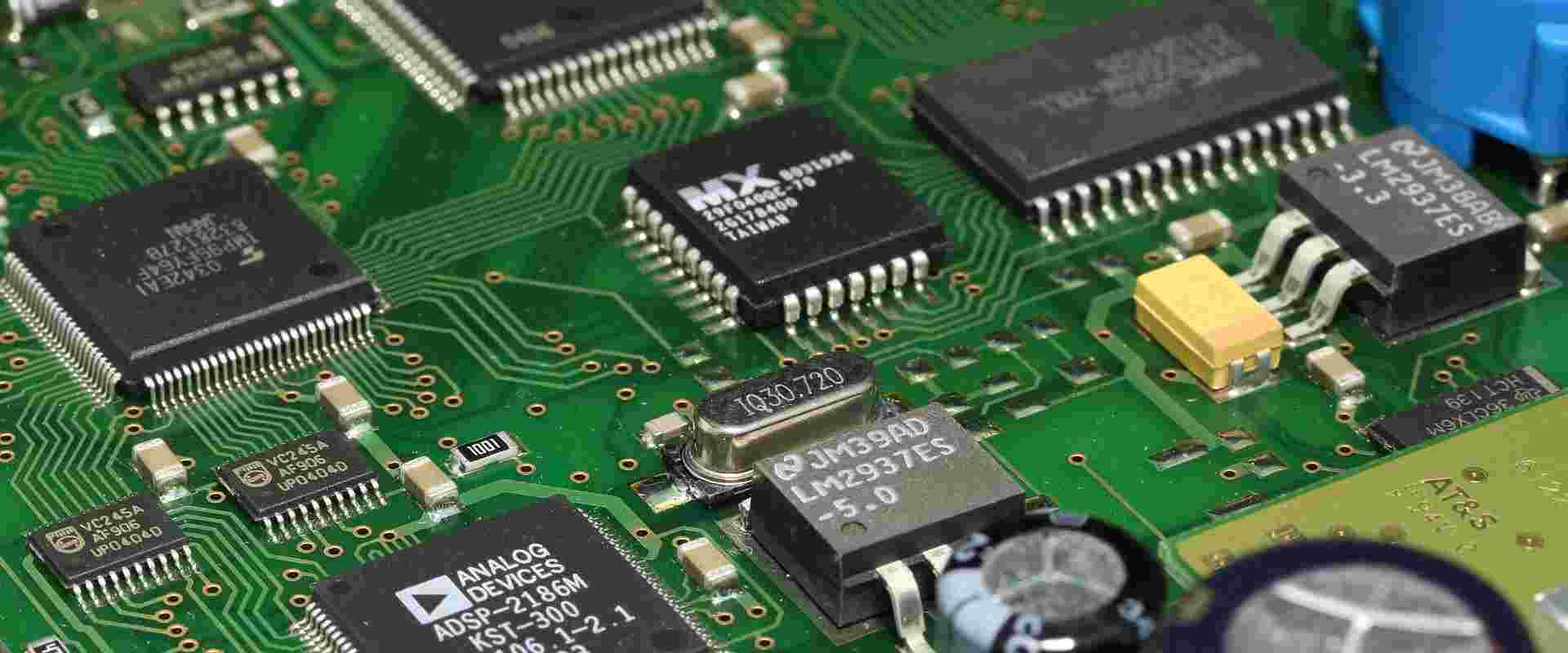

Inqubo ye-welding ngokuvamile yenziwa ngokuhambisana nokuhleleka kwemishini kusukela phansi kuya phezulu futhi kusukela ezincane kuya ezinkulu. Okuhamba phambili kunikezwa ukushisela ama-chips esekethe ahlanganisiwe.

Ngemva kokuphothulwa kwe-welding, hlola izinga lokushisela nokuthembeka. Uma kukhona okungalungile, lungisa noma ushise kabusha ngesikhathi.

Emsebenzini we-welding wangempela, ukushiswa kwebhodi lesifunda esinezinhlangothi ezimbili kudinga ukuhambisana ngokuqinile nezicaciso zenqubo efanele kanye nezidingo zokusebenza ukuze kuqinisekiswe ikhwalithi nokuthembeka kokushisela, kuyilapho kuqashelwa ukusebenza okuphephile ukuze kugwenywe ukulimala ngokwayo nasezizungezile. imvelo.