Ekwakhiweni kwesakhiwo se-PCB, ukwakheka kwezakhi kubalulekile, okunquma izinga elicocekile nelihle lebhodi nobude kanye nobungako bocingo oluphrintiwe, futhi kunomthelela othile ekuthembekeni komshini wonke.

Ibhodi yesifunda elihle, ngaphezu kokugcwaliseka komgomo womsebenzi, kepha futhi ukubheka i-EMI, EMC, ukuphuma kwe-ESD), ubuqotho besiginali nezinye izici zikagesi, kodwa nokubheka izinkinga zokushisa ukushisa okushisa.

Izidingo zokucaciswa kwe-PCB

1, funda idokhumenti yokuchaza design, hlangana nesakhiwo esikhethekile, imodyuli ekhethekile nezinye izidingo zesakhiwo.

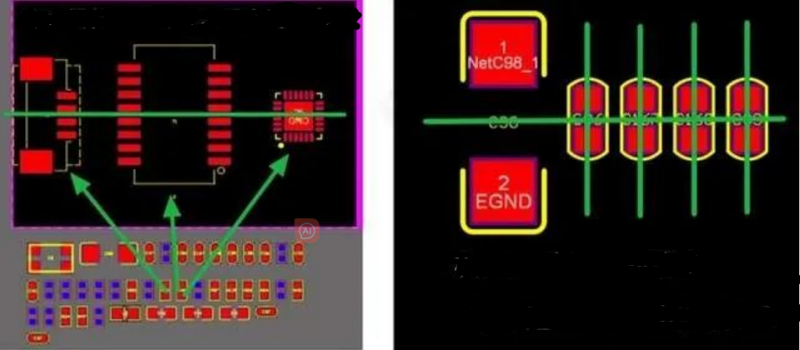

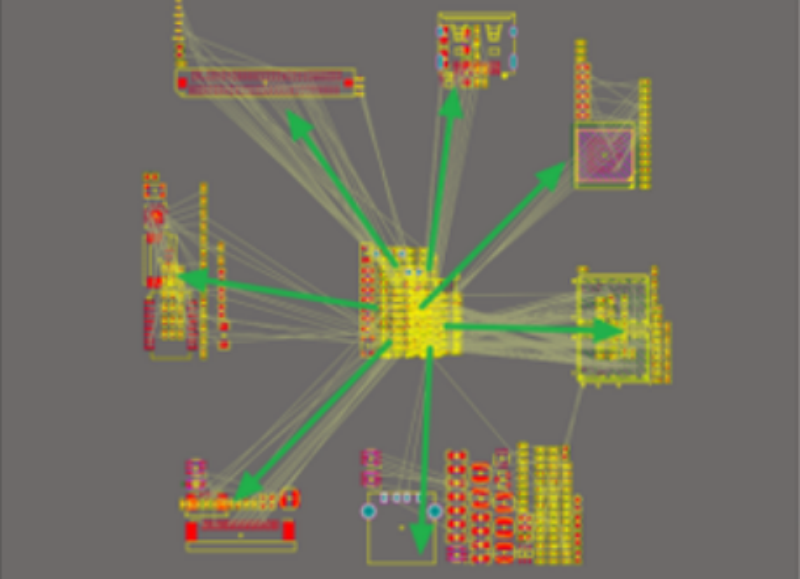

2, setha i-Layout Grid Khomba ku-25mil, ingahambisana nephuzu legridi, izikhala ezilinganayo; Imodi yokuqondanisa inkulu ngaphambi kokuncane (amadivaysi amakhulu namadivayisi amakhulu aqondaniswe kuqala), futhi imodi yokuqondanisa iyisikhungo, njengoba kukhonjisiwe kulokhu okulandelayo

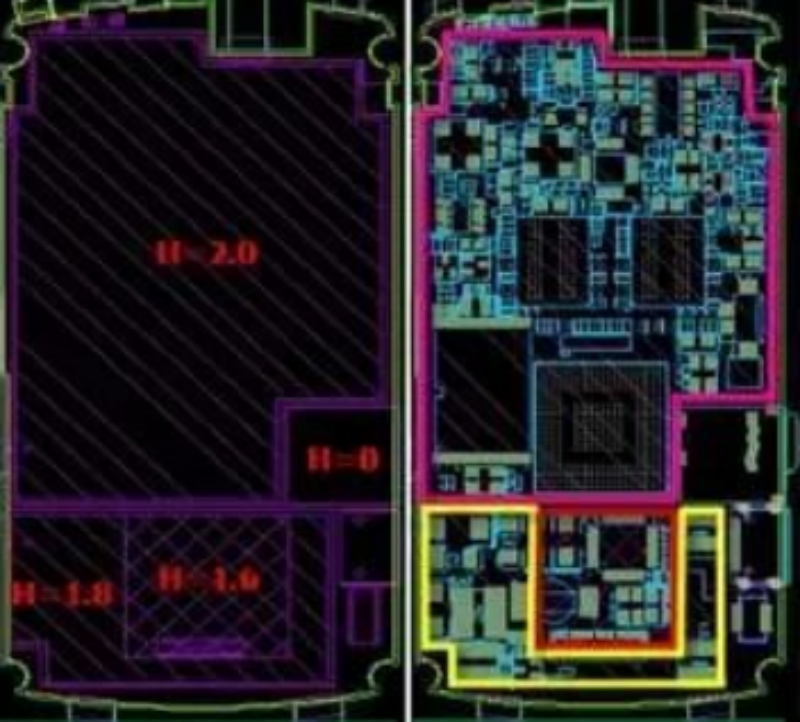

3, hlangana nomkhawulo wokuphakama kwendawo evinjelwe, isakhiwo kanye nokwakheka kwensiza ekhethekile, izidingo zendawo ezivinjelwe.

① Umdwebo o-1 (kwesobunxele) ngezansi: Izidingo zokuphakama, ezimakwe kahle engxenyeni yemishini noma isendlalelo sokumaka, elula yokuhlola kamuva;

.

Ukuhlelwa kwesakhiwo kanye namadivayisi akhethekile kungabekwa kahle izixhumanisi noma izixhumanisi zohlaka lwangaphandle noma umugqa wesikhungo sezinto.

I-4, ukwakheka kufanele kube nesakhiwo sangaphambi kokuhlelwa kuqala, ungatholi ibhodi ukuqala ukwakheka ngqo, i-Pre-BOORK ibhekane nokuhlaziywa kwesiginali, ku-PCB Board ukudweba isikhundla esilinganiselwe se-PCB kanye nosayizi webanga lokusebenza. Dweba umugqa osizayo u-40mil, futhi uhlole ubuqiniso bokuhlelwa phakathi kwamamojula namamojula ngokusebenzisa imisebenzi engenhla, njengoba kukhonjisiwe kwisibalo esingezansi.

I-5, ukwakheka kudinga ukucubungula isiteshi esishiya umugqa wamandla, akufanele kube mnene kakhulu, ngokuhlelela ukuthola ukuthi amandla avela kuphi, ahlanganise nomuthi wamandla

I-6, izingxenye ezishisayo (ezinjenge-electrolytic capacitor, i-crystal oscillators) ukwakheka kufanele kube kude kakhulu nokuhlinzekwa kwamandla namanye amadivaysi aphezulu afudumele, ngangokunokwenzeka ku-Upper Vent

7, ukuhlangana nokwehlukanisa okubucayi okubucayi, ibhalansi yebhodi lonke, ukubhuka kwesiteshi sonke sebhodi

Ama-voltage aphezulu kanye namasiginali aphezulu ahlukaniswe ngokuphelele ahlukaniswe ngokuphelele nezimpawu ezibuthakathaka zemisivu emincane nama-voltages aphansi. Izingxenye eziphakeme ze-voltage zivezwa kuzo zonke izingqimba ngaphandle kwethusi ezengeziwe. Ibanga le-creeplage phakathi kwezingxenye eziphakeme ze-voltage liyahlolwa ngokuya ngethebula elijwayelekile

Isiginali ye-analog ihlukaniswe nesiginali yedijithali ngokuhlukaniswa okungenani kwe-20mil okungenani, futhi i-analog ne-RF ihlelwe ku-'-' 'font noma i-'L' Shape ngokuya ngezidingo ekwakheni i-modular design

Isiginali yemvamisa ephezulu ihlukaniswe nesibonakaliso semvamisa ephansi, ibanga lokuhlukanisa okungenani okungenani i-3mm, futhi ukwakheka kwesiphambano akunakuqinisekiswa

Ukuhlelwa kwamadivayisi wesiginali asemqoka njenge-Crystal Oscillator kanye nomshayeli wewashi kufanele kube kude kakhulu nokuhlelwa kwesifunda, hhayi onqenqemeni lwebhodi, okungenani ku-10mm kude nomngcele webhodi. I-crystal ne-crystal oscillator kufanele ibekwe eduze kwe-chip, ibekwe ungqimba olufanayo, ungaxuba izimbobo, bese ubeka isikhala somhlaba

Isifunda esifanayo samukele ukwakheka okujwayelekile kwe- "Symmetrical"

Ngemuva komklamo we-PCB, kufanele sihlaziywe futhi sihlolwe ukwenza umkhiqizo bushelelezi ngokwengeziwe.