Ngokusho komdwebo wokujikeleza okuthuthukile, ukumbumbuluzwa kungenziwa futhi i-PCB ingenziwa ngokuthumela ifayela le-Gerber / Drill. Noma ngabe yini umklamo, onjiniyela badinga ukuqonda kahle ukuthi imibuthano (kanye nezakhi ze-elekthronikhi) kufanele ibekwe kanjani nokuthi basebenza kanjani. Kwabanjiniyela be-elekthronikhi, ukuthola amathuluzi wesoftware afanelekile e-PCB Design angaba umsebenzi owesabekayo. Amathuluzi wesoftware asebenza kahle kwiphrojekthi ye-PCB eyodwa kungenzeka angasebenzi kahle kwabanye. Onjiniyela bafuna amathuluzi okuklama webhodi anembile, aqukethe izici eziwusizo, azinze ngokwanele ukukhawulela ubungozi, futhi ube nomtapo wezincwadi onamandla ozenza zilungele amaphrojekthi amaningi.

Inkinga ye-Hardware

Kumaphrojekthi we-IOT, ukuhlanganiswa kubalulekile ekusebenzeni nasekuthembekeni, kanye nokuhlanganiswa kwezinto ezisebenzayo nezingezona ezempiyutha kuma-PCB zidinga ukuxhumanisa phakathi kwezinhlobonhlobo zikagesi nezemishini zokwakheka okuhlukahlukene. Ikakhulu, njengoba osayizi bezakhi beqhubeka nokuncipha, ukufudumeza kukagesi kuma-PCB kuya ngokuya kubucayi. Ngasikhathi sinye, izidingo ezisebenzayo ziyavuka. Ukufeza ukusebenza okususelwa ekusebenzeni komklamo, impendulo yokushisa, indlela yokuziphatha yezinto zikagesi ebhodini, futhi ukuphathwa okuphezulu okushisayo kubalulekile ekusebenzeni nasekuthembekeni kohlelo.

I-PCB kumele ibe yodwa ukuqinisekisa ukuvikelwa. Imibuthano emifushane ivinjelwa ukuvikela umkhondo wethusi obekwe ebhodini ukudala uhlelo lwe-elekthronikhi. Uma kuqhathaniswa nezinye izindlela ezibiza kakhulu njengephepha lokunamathisela ama-resin anamanzi (SRBP, FR-1, Fr-2), i-FR-4 ifanelekile njengekhono lokugcina eliphansi ngenxa yedatha yalo ebonakalayo, ikakhulukazi amandla okuvimbela okuphezulu ngenxa yokuphikisana okuphezulu, futhi iqiniso lokuthi lithola amanzi amancane kunezinye izinto. I-FR-4 isetshenziswa kabanzi ezakhiweni eziphakeme kakhulu kanye nemishini yezimboni nezempi. Iyahambelana nokufakwa okuphezulu kakhulu (i-Ultra-High Vacuum noma i-UHV).

Kodwa-ke, i-FR-4 njenge-PCB substrate ibhekene nenombolo yokulinganiselwa, esuka ekwelashweni kwamakhemikhali asetshenziswa ekukhiqizeni. Ikakhulu, lokho okubonakalayo kuthambekele ekwakhekeni kwe-inclusions (Bubbles) kanye ne-streaks (ama-bubble amade), kanye nokuguqulwa kwe-deform yengilazi. Lezi ziphutha zingadala amandla angqubuzana ahambisanayo nokusebenza kwe-PCB wiring. Indwangu entsha yengilazi ye-epoxy ixazulula lezi zinkinga.

Ezinye izinto ezisetshenziswayo ezisetshenziswayo zifaka i-polymide / ingilazi fiber (esekela amazinga okushisa aphezulu futhi kunzima) kanye ne-kapton (eguquguqukayo, engasindi, efanelekile yezicelo ezifana nokubonisa kanye namakhibhodi). Izici okufanele zicatshangelwe lapho ukhetha izinto zokwenziwa kwe-dielectric (substrates) zifaka phakathi ukunwetshwa kwe-thermal (CTE), izinga lokushisa le-Glass (TG), ukuvumelanisa okushisayo, nokuqina kwemishini.

Ama-PC / aerospace ama-PCB adinga ukucatshangelwa okukhethekile kokuklama okususelwa ekucacisweni kwesakhiwo kanye ne-100% Design for Test (DFT) ukumbozwa. Izinga le-Mil-Std-883 lisungula izindlela nezinqubo zokuhlola amadivaysi ama-microelectronic alungele izinhlelo zamasosha nezempi, kufaka phakathi ukuhlolwa kwemishini kanye nogesi, izinqubo zokukhiqiza, nezinye izinqubo zokuqinisekisa ukuqinisekisa amazinga angaguquki wekhwalithi nokwethembeka kulo lonke uhlelo. Ukusetshenziswa okuhlukahlukene kwamadivayisi anjalo.

Ngaphezu kokuhlangana namazinga ahlukahlukene, ukwakheka kwe-acleodive system electronive kumele kulandele uchungechunge lwemithetho, njengokuhlolwa kwe-AEC-Q100 Mechanical kanye ne-elekthronikhi yokufaka izifunda ezihlanganisiwe. Imiphumela yeCrostalk ingaphazamisa ukuphepha kwemoto. Ukunciphisa le miphumela, abaklami be-PCB kumele bachaze ibanga phakathi komugqa wesiginali kanye nomugqa wamandla. Idizayini nokuma okulinganiswayo kuvuselelwa amathuluzi wesoftware aqokomisa izici zomklamo ezidinga ukuguqulwa okuqhubekayo ukuze akwazi ukuhambisana nemikhawulo yokuphazamiseka kanye nemibandela yokuhlanza ukushisa ukugwema ukusebenza kohlelo.

Amanothi:

Ukuphazanyiswa kwesifunda uqobo akusona usongo lwekhwalithi yesiginali. I-PCB emotweni igcwele umsindo, oxhumana nomzimba ngezindlela eziyinkimbinkimbi zokufaka amanje kwangaphambi kokujikeleza esifundeni. Ama-voltage spikes kanye nokushintshashintsha kwezimo ezidalwe yizinhlelo zezimoto zokulahla kungacindezela izingxenye kude kakhulu nokubekezelela kwemishini.

Inkinga yesoftware

Amathuluzi we-PCB Layout Anamuhla kufanele abe nezinhlanganisela eziningi ezisebenzayo ukuze ahlangabezane nezidingo zabaqambi. Ukukhetha ithuluzi elilungile lesakhiwo kufanele kube ukucatshangelwa kokuqala ku-PCB Design futhi akufanele kunganakwa. Imikhiqizo evela kwimidwebo ye-Mentor, amasistimu we-Orcad, ne-altium phakathi kwamathuluzi we-PCB Layout yanamuhla.

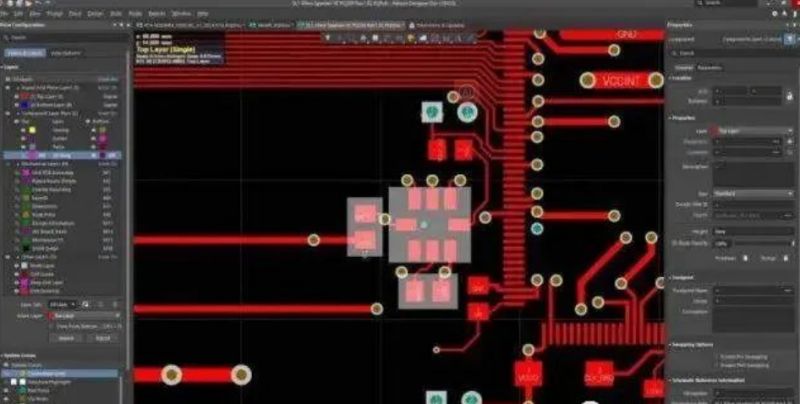

Umqambi we-Altium

I-Altium Designer ingenye yamaphakeji we-PCB end-End Design emakethe namuhla. Ngomsebenzi ozenzakalelayo we-wiring, ukusekelwa kokulungiswa kobude bomugqa kanye nemodeli ye-3D. I-Altium Designer ifaka amathuluzi wayo yonke imisebenzi yokuklama yesifunda, kusuka ku-Schematic Hatture kuya ku-HDL kanye nokumbumbuluzwa kwe-Circuit, ukuhlaziya kwesiginali, ukuthuthukiswa kwe-PCGA, kanye ne-FPGA

Ipulatifomu ye-Mentor Graphics 'PCB ibheka izinselelo eziphambili ezibhekene nabaklami bohlelo lwanamuhla: Ukunembile, ukusebenza - nokusebenzisa kabusha ukuhlelwa okunezinhloso ezihlelwe kabusha; Ukuzilibazisa okusebenzayo ezindaweni eziminyene neziyinkimbinkimbi; Kanye nokwenza kahle kwe-elekthrolechani. Isici esiyisihluthulelo sesiteji kanye nokwenziwa okusha kwemboni kungumdwebo we-sketch, okunikeza abaklami ukulawula okugcwele okusebenzayo kwenqubo ezenzakalelayo / esisizwayo, kukhiqiza imiphumela yekhwalithi efanayo, kepha esikhathini esiningi.

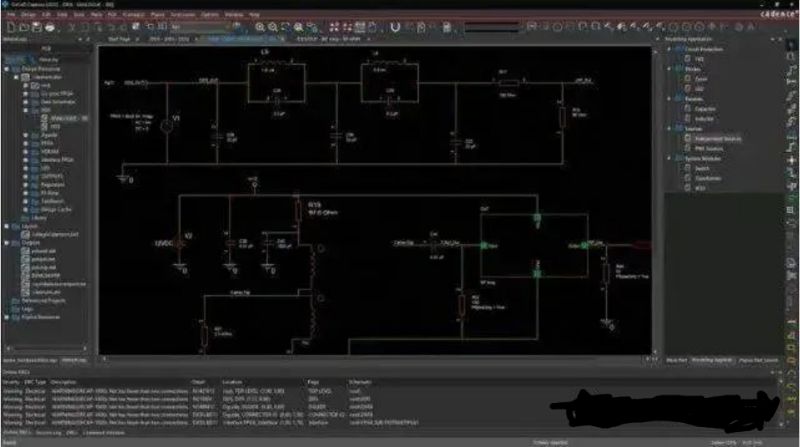

Umhleli we-OrCAD PCB

I-OrCAD PCB Editor iyimvelo exhumana eyenzelwe ukuklama iBhodi kunoma yiliphi izinga lobuchwepheshe, kusuka kokulula kuya kokuyinkimbinkimbi. Ngenxa yesikali sayo sangempela se-Cadence Allegro i-PCB Solutions, i-Orcad PCB Isihleli isekela ukuthuthukiswa kobuchwepheshe kwamaqembu okuklama futhi iyakwazi ukuphatha izingqinamba (isivinini esikhulu, ubuqotho besiginali, njll.) Ngenkathi ilimo yefayela

Ifayela le-Gerber

Ifomethi yefayela le-Gerber elijwayelekile lisetshenziselwa ukudlulisa imininingwane yokuklama ukukhiqizwa kwe-PCB. Ngezindlela eziningi, i-Gerber ifana nama-PDF kuma-elekthronikhi; Kuyindlela nje encane yefayela ebhalwe olimini oluhlanganisiwe lomshini wokulawula. Lawa mafayela akhiqizwa isoftware yesekethe yokujikeleza futhi athunyelwe kumkhiqizi we-PCB kwisoftware ye-CAM.

Ukuhlanganisa ngokuphepha Izinhlelo ze-elekthronikhi ezimotweni nakwezinye izinhlelo eziyinkimbinkimbi ziveza ukucatshangelwa okubalulekile kwazo zombili i-Hardware ne-software. Onjiniyela bahlose ukunciphisa inani lokuqamba ama-Iterations nesikhathi sokuthuthuka, esinezinzuzo ezibalulekile kubaqambi abaqambise ukugeleza komsebenzi.