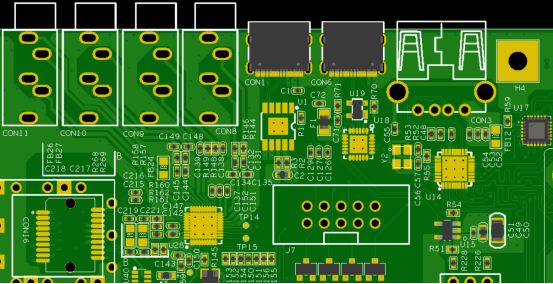

Mayelana ne-PCB Layout nenkinga ye-wiring, namuhla ngeke sikhulume ngokuhlaziywa kobuqotho be-Signal (SI), ukuhlaziya ukuhambisana kwe-electromagnetic (EMC), ukuhlaziya ubuqotho bamandla (PI). Ukukhuluma nje ngokuhlaziywa kokulwa (DFM), ukwakheka okungenangqondo kokwakheka kuzoholela nasekwehlulekeni komklamo womkhiqizo.

I-DFM ephumelelayo ekwakhekeni kwe-PCB iqala ngokusetha imithetho yokwakhiwa ukuze i-akhawunti ngezingqinamba ezibalulekile ze-DFM. Imithetho ye-DFM eboniswe ngezansi ikhombisa amanye amakhono okuklama wanamuhla abakhiqizi abaningi abangabathola. Qinisekisa ukuthi imikhawulo ebekwe emithethweni ye-PCB Design ayiphuli ngakho ukuze imikhawulo ye-design ejwayelekile ingaqinisekiswa.

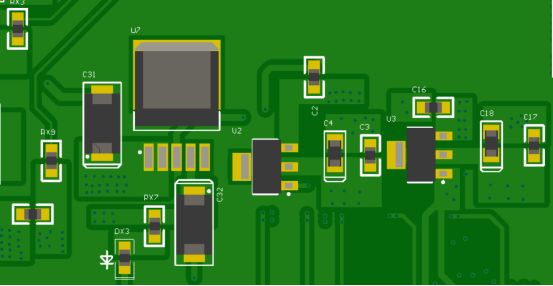

Inkinga ye-DFM ye-PCB Routing incike ekwakhekeni okuhle kwe-PCB, futhi imithetho yomzila ingaba isethiwe, kufaka phakathi inani lezikhathi zokugoqa, inani lezimbobo zokuzithoba, i-wiring yezentengiso yenziwa kuqala ukuxhumanisa imigqa emifushane ngokushesha, bese kuthi kwenziwa i-labyrinth wiring. I-Global Routing Path Optimization yenziwa kwizintambo ezizobekwa kuqala, futhi i-wiring izama ukuthuthukisa umphumela onke kanye nokukhiqizwa kwe-DFM.

Amadivayisi we-1.SMT

Isikhala sokuhlelwa kwensiza sihlangabezana nezidingo zemihlangano, futhi ngokuvamile sikhulu kune-20mil yamadivayisi afakwe ebusweni, ama-80mil amadivayisi we-IC, kanye nama-200mi amadivayisi we-BGA. Ukuze uthuthukise ikhwalithi kanye nesivuno senqubo yokukhiqiza, ukuhlukaniswa kwensiza kungahlangabezana nezidingo zomhlangano.

Ngokuvamile, ibanga phakathi kwama-SMD Pads ezikhonkwane zedivayisi kufanele libe likhulu kune-6mil, futhi umthamo wokuqamba we-soler soler Bridge ngu-4mil. Uma ibanga phakathi kwama-SMD Pads lingaphansi kwama-6mil futhi ibanga phakathi kwewindi le-solder lingagcinwanga, okuholela ezingcebeni ezinkulu ze-solder (ikakhulukazi phakathi kwezikhonkwane) kwinqubo emfushane.

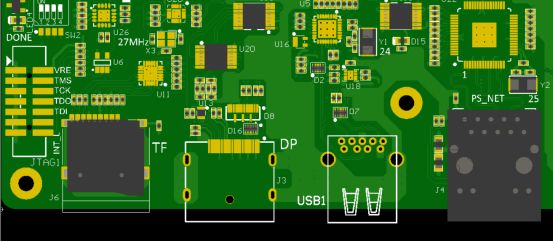

Idivayisi engu-2.Dip

Ukuhlukaniswa kwe-PIN, ukuqondiswa kanye nokuhlukaniswa kwamadivayisi kwinqubo ye-Wave Soldering ye-Wave kufanele kubhekwe. Ukuhlukaniswa kwe-PIN enganele yedivayisi kuzoholela ekutholeni i-tin ethengisa, okuzoholela kumjikelezo omfushane.

Abaqambi abaningi banciphisa ukusetshenziswa kwamadivayisi we-in-line (thts) noma bawabeke ohlangothini olufanayo lweBhodi. Kodwa-ke, amadivaysi ku-In-line ajwayele ukungavinjelwa. Endabeni yenhlanganisela, uma kufakwa kudivayisi e-In-line ungqimba oluphezulu bese kufakwa idivaysi engezansi engxenyeni engezansi, kwezinye izikhathi, kuzothinta i-wave soldering eyodwa. Kulokhu, izinqubo ezibiza kakhulu ze-Welding, ezinjenge-welding ezikhethiwe, ziyasetshenziswa.

Ibanga eliphakathi kwezakhi kanye nonqenqema lwepuleti

Uma kungukushibilika komshini, ibanga phakathi kwezakhi ze-elekthronikhi kanye nomphetho webhodi ngokuvamile kungu-7mm (abakhiqizi abahlukene be-welding banezidingo ezihlukile), kodwa futhi zingezelelwa ku-PCB Production Edge, ukuze kufakwe izidingo ze-PCB ebhodini, isikhathi eside njengoba kufanelekile nge-wiring.

Kodwa-ke, lapho umphetho weplate ufakwa, kungahle kuhlangane nomqondisi womshini futhi kulimaze izingxenye. I-Pad Pad emaphethelweni epuleti izosuswa kwinqubo yokukhiqiza. Uma i-pad incane, ikhwalithi ye-welding izothinteka.

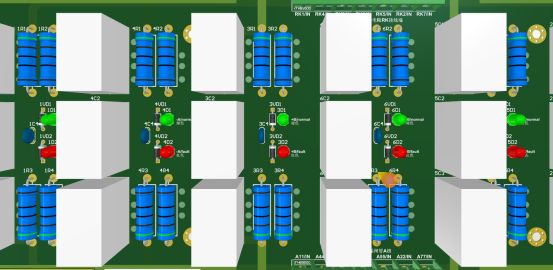

4.Izincwadi zamadivayisi aphezulu / aphansi

Kunezinhlobo eziningi zezakhi ze-elekthronikhi, bobunjwa obuhlukile, kanye nemigqa ehlukahlukene eholayo, ngakho-ke kunomehluko endaweni yomhlangano amabhodi aphrintiwe. Ukuhlelwa okuhle akunakwenza kuphela ukusebenza komshini ezinzile, ubufakazi obushaqisayo, butha ukulimala, kepha futhi ungathola umphumela omuhle futhi omuhle ngaphakathi komshini.

Amadivayisi amancane kufanele agcinwe ebanga elithile azungeze amadivayisi aphezulu. Ibanga ledivaysi ekuphakameni kwedivaysi lincane, kukhona igagasi elishisekayo elingalingani, elingadala ingozi yokufudumala noma ukulungiswa ngemuva kokushiswa.

5.Device to device spacecing

Ngokucutshungulwa kwe-General SMT, kuyadingeka ukubheka amaphutha athile ekukhuphukeni komshini, futhi unake lula ukulungiswa nokuhlolwa okubukwayo. Lezi zinto ezimbili eziseduze akufanele zisondele kakhulu futhi ibanga elithile eliphephile kufanele lishiywe.

Izikhala phakathi kwezakhi ze-flake, ama-sot, ama-spic kanye nezakhi ze-flake zingu-1.25mm. Izikhala phakathi kwezakhi ze-flake, ama-sot, ama-spic kanye nezakhi ze-flake zingu-1.25mm. I-2.5mm phakathi kwengxenye ye-PLCC ne-Flake, i-SAIC ne-QFP. I-4mm phakathi kwama-PLCCs. Lapho uklama ama-plcc amasokethi, kufanele kuthathwe ukunakekelwa ukuvumela usayizi we-plcc socket (i-PLCC PIN ingaphakathi phansi kwesokhethi).

6.Line Ububanzi / Line Little

Kwabaqambi, kwinqubo yokwakheka, asikwazi ukubheka kuphela ukunemba nokuphelela kwezidingo zokwakhiwa, kukhona umkhawulo omkhulu inqubo yokukhiqiza. Akunakwenzeka ukuthi ifektri yebhodi ukudala umugqa omusha wokukhiqiza ukuze uzelwe umkhiqizo omuhle.

Ngaphansi kwezimo ezijwayelekile, ububanzi bentambo bomugqa ophansi bulawulwa ku-4 / 4mil, bese umgodi ukhethwe ukuba ube ngu-8mil (0.2mm). Ngokuyisisekelo, bangaphezulu kwama-80% abakhiqizi be-PCB abangakhiqiza, futhi izindleko zokukhiqiza ziphansi kakhulu. Ububanzi obuncane be-Line nebanga le-Line bungalawulwa ku-3 / 3mil, kanye ne-6mil (0.15mm) bangakhethwa emgodini. Ngokuyisisekelo, abakhiqizi abangaphezu kwama-70% PCB bangakukhiqiza, kepha intengo iphakeme kancane kunecala lokuqala, hhayi ngaphezulu kakhulu.

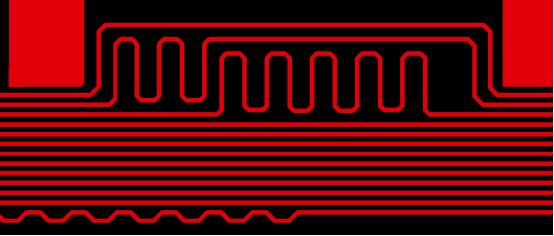

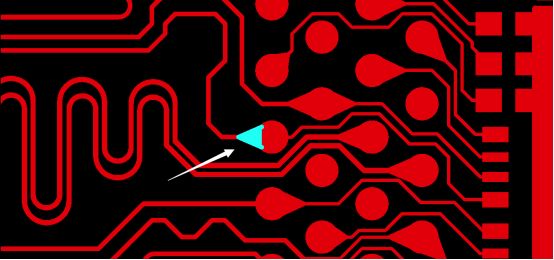

7.Nan Angle / I-Engle Engela Ngakwesokudla

Umzila obukhali we-angle ngokuvamile anqatshelwe e-wiring, umzila we-angle ongakwesokudla ngokuvamile kuyadingeka ukugwema isimo ku-PCB Routing, futhi cishe ube ngenye yezindinganiso zokukala ikhwalithi ye-wiring. Ngoba ubuqotho besiginali buyathinteka, i-wiring ye-angle-angle izokhiqiza amandla angeziwe okuhambisana nokuqanjwa.

Enqubweni yokwenza ipuleti yepuleti, izintambo ze-PCB zihlangana nge-angle ebukhali, ezodala inkinga ibizwa nge-angle acid. Esixhumanisi sePCB Circuing Conchning, ukugcwala ngokweqile kwePCB Circuit kuzobangelwa e "acid angle", okuholela enkingeni ye-PCB Circuit break break. Ngakho-ke, onjiniyela be-PCB badinga ukugwema ama-engeli abukhali noma angajwayelekile e-wiring, futhi alondoloze i-angle engu-45 degree ekhoneni le-wiring.

8.Copper Strip / Island

Uma kungukuthi ithusi elikhulu ezanele esiqhingini, lizoba yi-antenna, elingadala umsindo nokunye ukuphazamiseka ngaphakathi kweBhodi (ngoba ithusi layo alinasisekelo - lizoba umqoqi wesiginali).

Imichilo yeCopper neziqhingi ziyizingqimba eziningi eziyizicaba zethusi elintantayo elintantayo, elingadala izinkinga ezinkulu emkhombeni we-acid. Izindawo ezincane zethusi ziye zaziwe ukucisha iphaneli ye-PCB futhi ziye kwezinye izindawo ezingene kwiphaneli, kubangele umjikelezo omfushane.

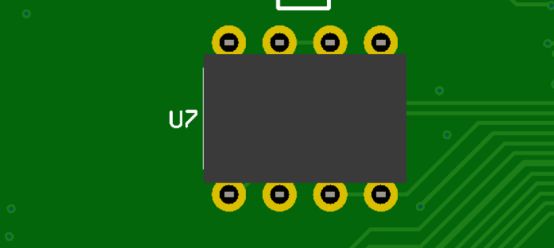

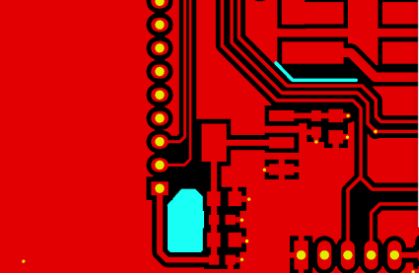

9.Indandatho yezimbobo zokumba

I-hole ring isho indandatho yethusi ezungeze umgodi wokumba. Ngenxa yokubekezelelana kwinqubo yokukhiqiza, ngemuva kokumba, ukushayela, kanye neplanethi yethusi, indandatho yethusi esele ezungeze umgodi we-drill ayihlali ishaya indawo ephelele yepad ngokuphelele, okungenza umgodi ukhale ukhala.

Uhlangothi olulodwa lwendandatho ye-hole kumele lube lukhulu kune-3.5mil, futhi indandatho ye-plug-in hole kumele ibe nkulu kune-6mil. Indandatho yemgodi incane kakhulu. Esezinhlelweni zokukhiqizwa nokwenziwa, umgodi wokumba unezinto zokubekezelelana futhi ukuqondanisa komugqa nakho kunokubekezelelana. Ukuphambuka kokubekezelela kuzoholela emgodini wokukhala komjikelezo ovulekile.

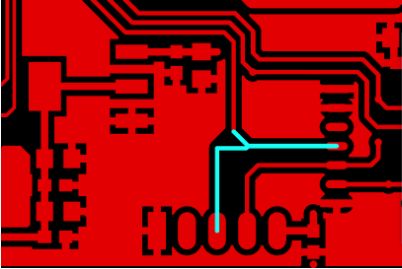

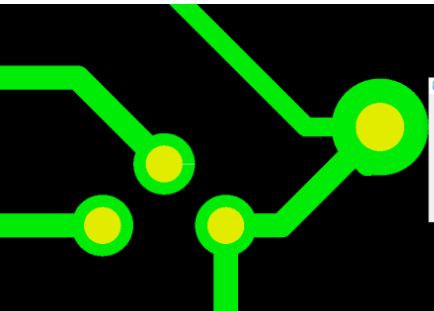

10. Amaconsi we-wiring

Ukungeza izinyembezi ku-PCB Wiring kungenza ukuxhumana kwe-PCB ku-PCB ezinzile, ukuthembeka okuphezulu, ukuze uhlelo lube luzinzile, ngakho-ke kuyadingeka ukwengeza izinyembezi ebhodini lesekethe.

Ukungezwa kwamaconsi ngezinyembezi kungakugwema ukuxhumeka kwephuzu lokuxhumana phakathi kocingo kanye ne-pad noma nge-wire kanye nomgodi wokushayela lapho iqhude le-Pilot lapho lithinteka ngamandla amakhulu angaphandle. Lapho ungeza amaconsi we-izinyembezi ku-welding, angavikela i-pad, agweme ukushisa okuningi ukwenza i-pad iwele, futhi igweme ukufakwa okungalingani kanye nokuqhekeka okubangelwa yi-hole deflection ngesikhathi sokukhiqizwa.