Ukwethulwa kweNge-pad-pad:

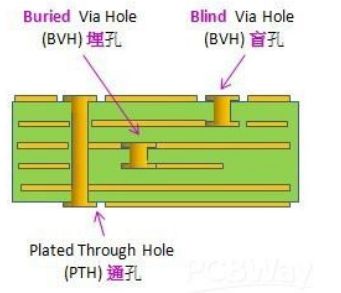

Kuyaziwa ukuthi i-vias (nge-via) ingahlukaniswa i-Pulated nge-hole, i-virol vias hole kanye nomgodi we-vias ongcwatshwe, onemisebenzi ehlukene.

Ngokuthuthukiswa kwemikhiqizo ye-elekthronikhi, i-vias idlala indima ebalulekile ekuxhumekeni kwe-internconction kwamabhodi wesifunda aphrintiwe. I-Via-In-Pad isetshenziswa kabanzi ku-PCB encane ne-BGA (i-Ball Grid Array). Ngokuthuthuka okungenakugwenywa kobuningi obuphezulu, i-BGA (i-ball grid array) kanye ne-smd chip miniaturization, ukusetshenziswa kobuchwepheshe be-via-in-pad kuya ngokuya kubaluleke kakhulu.

UVias emaphaketheni anezinzuzo eziningi ezingaphezu kwempumputhe futhi zingcwatshwe vias:

. Ilungele i-pitch BGA enhle.

. Kuyinto elula ukuklama i-PCB ye-density ephezulu bese ugcine isikhala se-wiring.

. Ukuphathwa okungcono kakhulu kwe-thermal.

. I-anti-low inductance nokunye ukwakheka okuphezulu.

. Ihlinzeka indawo ethambile yezakhi.

. Yehlisa indawo ye-PCB futhi uthuthukise ukuthuthukisa.

Ngenxa yalezi zinzuzo, i-via-in-pad isetshenziswa kabanzi kuma-PCB amancane, ikakhulukazi ku-PCB Design lapho kudingeka khona ukudluliswa kokushisa nesivinini esikhulu nge-BGA Litch. Yize i-viving ne-vias eyimpumputhe engcwatshwe yandisa ukwehla futhi igcina isikhala kuma-PCB, ama-vias kuma-pads asawukukhetha okungcono kakhulu kokuphathwa kwe-thermal kanye nezinto ezisheshayo zokuqamba.

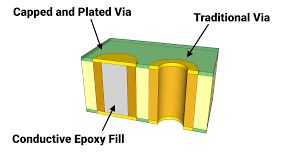

Ngokwethembekile ngenqubo yokugcwalisa / yokugcwalisa i-capling, ubuchwepheshe be-via-in-pad bungasetshenziselwa ukukhiqiza ukukhiqiza ama-PCB aphezulu aphezulu ngaphandle kokusebenzisa izindlu zamakhemikhali nokugwema amaphutha okuthengisa. Ngaphezu kwalokho, lokhu kunganikeza izintambo ezingezelelweyo zokuxhuma kwemiklamo ye-BGA.

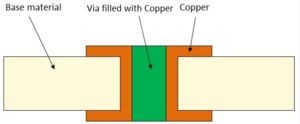

Kunezinto zokugcwalisa ezahlukahlukene zokugcwalisa umgodi epuletini, ukunamathisela kwesiliva nangokunamathisela kwethusi kuvame ukusetshenziselwa izinto ezisebenzayo, futhi i-resin isetshenziselwa okuvame ukusetshenziswa kwezinto ezingeyona