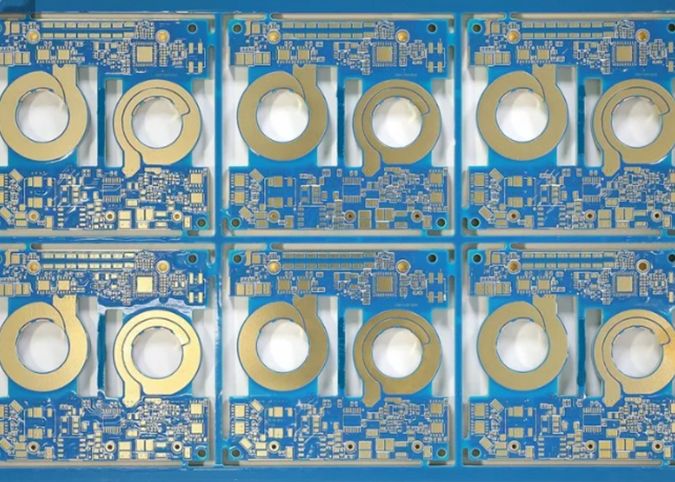

Izinto zokwakha zesekethe zithembele kumakhondakta wekhwalithi ephezulu nezinto zokwakha ze-dielectric ukuxhuma izingxenye zesimanje eziyinkimbinkimbi ukuze zisebenze kahle. Kodwa-ke, njengamakhondaktha, lawa makhondaktha ekhopha e-PCB, noma amabhodi e-DC noma ama-mm Wave PCB, adinga ukuvikelwa kokulwa nokuguga kanye ne-oxidation. Lokhu kuvikelwa kungafinyelelwa ngendlela ye-electrolysis kanye nezingubo zokucwiliswa. Bavame ukuhlinzeka ngamazinga ahlukahlukene ekhono lokushisela, ukuze kuthi noma kunezingxenye ezihlala zincane, i-micro-surface mount (SMT), njll., indawo yokushisela ephelele ingakhiwa. Kunezinhlobonhlobo zezingubo zokugqoka kanye nokwelapha okungaphezulu okungasetshenziswa kuma-copper conductors we-PCB embonini. Ukuqonda izici nezindleko ezihambisanayo zokwembozwa ngakunye nokwelashwa kwendawo kusisiza ukuthi senze ukukhetha okufanele ukuze sifinyelele ukusebenza okuphezulu nempilo ende yesevisi yamabhodi e-PCB.

Ukukhethwa kokugcina kwe-PCB akuyona inqubo elula edinga ukucatshangelwa kwenhloso ye-PCB nezimo zokusebenza. Ukuthambekela kwamanje kokupakisha okuminyene, iphimbo eliphansi, isekethe ye-PCB enesivinini esikhulu kanye ne-PCBS emincane, ezacile, enefrikhwensi ephezulu kubangela izinselele kubakhiqizi abaningi be-PCB. Amasekhethi e-PCB akhiqizwa ngamalayini esisindo se-foil ehlukahlukene yethusi nogqinsi olunikezwa abakhiqizi be-PCB ngabakhiqizi bezinto ezibonakalayo, abanjengoRogers, abe esecubungula laminates abe izinhlobo ezihlukahlukene ze-PCBS ukuze zisetshenziswe kuma-electronics. Ngaphandle kohlobo oluthile lokuvikela indawo, ama-conductor akusekhethi azokhipha i-oxidize ngesikhathi sokugcina. Ukwelashwa kwe-conductor surface kusebenza njengesithiyo esihlukanisa umqhubi nendawo. Ayivikeli nje kuphela umqhubi we-PCB ku-oxidation, kodwa futhi inikeza isixhumi esibonakalayo samasekhethi wokushisela nezingxenye, okuhlanganisa ukubopha okuholayo kwamasekethe ahlanganisiwe (ics).

Khetha indawo efanele ye-PCB

Ukwelashwa kwendawo efanele kufanele kusize ukuhlangabezana nesicelo sesekhethi ye-PCB kanye nenqubo yokukhiqiza. Izindleko ziyahlukahluka ngenxa yezindleko zempahla ehlukene, izinqubo ezahlukene kanye nezinhlobo zokuqeda ezidingekayo. Okunye ukwelapha okungaphezulu kuvumela ukwethembeka okuphezulu kanye nokuhlukaniswa okuphezulu kwamasekhethi aminyene, kanti okunye kungakha amabhuloho angadingekile phakathi kwamakhondaktha. Okunye ukwelashwa okungaphezulu kuhlangabezana nezidingo zempi kanye ne-aerospace, njengezinga lokushisa, ukushaqeka nokudlidliza, kuyilapho okunye akuqinisekisi ukwethembeka okuphezulu okudingekayo kulezi zinhlelo zokusebenza. Okubhalwe ngezansi ezinye zokwelapha ezingaphezulu kwe-PCB ezingasetshenziswa kumasekhethi asukela kumasekhethi e-DC kuya kumabhendi wamagagasi angamamilimitha kanye namasekhethi edijithali esivinini esikhulu (HSD):

●ENIG

●ENEPIG

●HASL

●Isiliva Lokucwiliswa

●I-Tin Yokucwiliswa

●LF HASL

●OSP

●Igolide eliqinile le-Electrolytic

● Igolide elithambile eliboshwe ngogesi

1.ENIG

I-ENIG, eyaziwa nangokuthi inqubo yamakhemikhali ye-nickel-gold, isetshenziswa kabanzi ekwelapheni okungaphezulu kwama-PCB board conductors. Lena inqubo elula ebiza kancane eyakha ungqimba oluncane lwegolide elishisekelayo phezu kongqimba lwe-nickel ebusweni bekhondakta, okuholela endaweni eyisicaba enekhono elihle lokushisela ngisho nakumasekhethi aminyene. Nakuba inqubo ye-ENIG iqinisekisa ubuqotho be- through-hole electroplating (PTH), iphinde ikhulise ukulahlekelwa komqhubi ngemvamisa ephezulu. Le nqubo inempilo ende yokugcina, ngokuhambisana nezindinganiso ze-RoHS, kusukela ekucubungulweni komkhiqizi wesifunda, kuya kunqubo yokuhlanganisa ingxenye, kanye nomkhiqizo wokugcina, inganikeza ukuvikelwa kwesikhathi eside kubaqhubi be-PCB, onjiniyela abaningi be-PCB bakhetha ukwelashwa kwendawo evamile.

2.ENEPIG

I-ENEPIG iwukuthuthukiswa kwenqubo ye-ENIG ngokwengeza ungqimba oluncane lwe-palladium phakathi kongqimba lwe-nickel lwamakhemikhali kanye nongqimba lwegolide lokucwenga. I-palladium layer ivikela ungqimba lwe-nickel (oluvikela umqhubi wethusi), kuyilapho ungqimba lwegolide luvikela kokubili i-palladium ne-nickel. Lokhu kwelashwa okungaphezulu kulungele amadivayisi okubopha kumkhondo we-PCB futhi kungaphatha izinqubo zokugeleza kabusha eziningi. Njenge-ENIG, i-ENEPIG iyahambisana ne-RoHS.

3.Ukucwiliswa kwesiliva

I-Chemical silver sedimentation iyinqubo yamakhemikhali engeyona eye-electrolytic lapho i-PCB icwiliswa ngokuphelele kusixazululo sama-ion esiliva ukubopha isiliva ebusweni bethusi. I-coating ewumphumela ivumelana kakhulu futhi ifana kune-ENIG, kodwa ayinakho ukuvikeleka nokuqina okuhlinzekwa ungqimba lwe-nickel ku-ENIG. Nakuba inqubo yayo yokwelapha ngaphezulu ilula futhi ibiza kakhulu kune-ENIG, ayifaneleki ukugcinwa isikhathi eside nabakhiqizi besekethe.

4.Ithini Lokucwiliswa

Izinqubo zokubeka uthayela wamakhemikhali zakha uthayela omncane omncane endaweni kakhondatha ngenqubo yezinyathelo eziningi ezihlanganisa ukuhlanzwa, ukucwiliswa okuncane, ukulungiswa kwesisombululo se-asidi, ukucwiliswa kwesisombululo se-non-electrolytic tin leaching, nokuhlanza okokugcina. Ukwelashwa kwethini kunganikeza ukuvikeleka okuhle kwekhopha namakhondaktha, kube nomthelela ekulahlekelweni okuphansi kokusebenza kwamasekhethi e-HSD. Ngeshwa, ithini elicwiliswe ngamakhemikhali aliyona enye yezindlela zokwelapha ezihlala isikhathi eside zekhondatha ngenxa yomphumela ithini eliba nawo ekhopha ngokuhamba kwesikhathi (okungukuthi, ukusakazeka kwensimbi eyodwa kwenye kunciphisa ukusebenza kwesikhathi eside komqhubi wesekethe). Njengesiliva yamakhemikhali, ithini lamakhemikhali liwuhlelo olunganawo umthofu, oluhambisana ne-RoHs.

5.OSP

Ifilimu yokuvikela i-organic welding (i-OSP) iyisivikelo esingeyona insimbi ehlanganiswe nesisombululo esisekelwe emanzini. Lokhu kuqedwa nakho kuyahambisana ne-RoHS. Kodwa-ke, lokhu kwelashwa okungaphezulu akunayo impilo yeshalofu ende futhi isetshenziswa kangcono ngaphambi kokuba isekethe nezingxenye zishiselwe ku-PCB. Muva nje, ulwelwesi olusha lwe-OSP luye lwavela emakethe, okukholakala ukuthi likwazi ukuhlinzeka ngokuvikeleka okuhlala njalo kwabaqhubi.

6.Electrolytic hard gold

Ukwelashwa kwegolide eliqinile kuyinqubo ye-electrolytic ehambisana nenqubo ye-RoHS, engavikela i-PCB ne-copper conductor ekufakweni kwe-oxidation isikhathi eside. Kodwa-ke, ngenxa yezindleko eziphakeme zezinto zokwakha, futhi ingenye yezingubo ezingaphezulu ezibiza kakhulu. Iphinde ibe nokushisela okubuthakathaka, ukushisela okungekuhle ekuhlanganiseni ukwelashwa kwegolide elithambile, futhi iyathobelana ne-RoHS futhi inganikeza indawo enhle ukuze idivayisi ihlangane nemikhondo ye-PCB.