Ukuvimbela izimbobo ekuqopheni nasekushiseni kuhlanganisa ukuhlola izinqubo ezintsha zokukhiqiza kanye nokuhlaziya imiphumela. Amaplanethi nama-welding voids avame ukuba nezimbangela ezikhonjelwe, njengohlobo lokunamathisela okuthengiswayo noma ukushayela okusetshenziswa kwinqubo yokukhiqiza. Abakhiqizi be-PCB bangasebenzisa amasu athile asemqoka ukukhomba nokubhekana nezimbangela ezijwayelekile zalezi void.

1.ADETHWA I-Reflux Izinga lokushisa ijika

Enye yezindlela zokuvimbela imithambo ye-welding ukuthi ilungise indawo ebucayi yejika le-reflux. Ukunikeza izigaba ezahlukene zesikhathi kungakhuphula noma ukunciphisa amathuba okuba vele avele. Ukuqonda izici zejika le-Return Curve kubalulekile ekuvinjelweni okuphumelelayo kwe-cavity.

Okokuqala, bheka izilungiselelo zamanje zesikhathi sokufudumeza. Zama ukwandisa izinga lokushisa noma ukunweba isikhathi sokuphumula sejika le-reflux. Izimbobo ze-Soler zingamangaza ngenxa yokushisa okunganele endaweni yokufika komsebenzi, ngakho-ke sebenzisa la masu ukubhekana nembangela yempande.

Izindawo zokushisa ezinamahloni nazo zibumbana ezintweni ezivelele ezinamanzi. Izikhathi ezimfishane zokuhleleka kungavumeli zonke izinto nezindawo zeBhodi ukufinyelela izinga lokushisa elidingekayo. Zama ukuvumela isikhathi esingeziwe sale ndawo yejika le-Reflux.

2. Sebenzisa i-flux encane

I-flux eningi kakhulu ingabi kakhulu futhi ivame ukuholela ekushiseni. Enye inkinga nge-havity ehlanganayo: ukugcwala kwe-flux. Uma i-flux ingenaso isikhathi esanele sokwehla, igesi eyeqile izobanjiswa futhi i-void izokwakheka.

Lapho kufakwa i-flux eningi kakhulu kwi-PCB, isikhathi esidingekayo ukuze i-flux ibekwe ngokuphelele seluliwe. Ngaphandle kokuthi wengeze isikhathi esengeziwe se-degassing, i-flux eyengeziwe izophumela kuma-peld voids.

Ngenkathi ungeza isikhathi esengeziwe se-degassing ungaxazulula le nkinga, uphumelela kakhulu ukunamathela kwinani le-flux elidingekayo. Lokhu kusindisa amandla nezinsizakusebenza futhi kwenza amalunga ahlanzekile.

3.Sebenzisa kuphela ukubhidliza okubukhali

Imbangela evamile yezimbobo zokufaka izimbobo imbi ngokumba umgodi. Ama-bits aluhlaza noma ukunemba kokumba okumpofu kungakhulisa amathuba okuba yi-debris ukwakheka ngesikhathi sokumba. Lapho lezi zingcindezi zinamathela kwi-PCB, zidala izindawo ezingenalutho ezingenakutholwa ngethusi. Lokhu kubeka engcupheni ukwenziwa, ikhwalithi kanye nokwethenjwa.

Abakhiqizi bangaxazulula le nkinga ngokusebenzisa izingcezu ezibukhali futhi ezibukhali ezibukhali. Sungula isheduli engaguquki yokubukhali noma ukufaka okunye ukushintshanisa izingcezu, njengekota. Lokhu kulungiswa okujwayelekile kuzoqinisekisa ikhwalithi yokushayela eguquguqukayo nge-hole

I-4.Zama i-template ehlukene yethempulethi

Idizayini yethempulethi esetshenziswe kwinqubo yokukhomba ingasiza noma ivimba ukuvikela ama-deleds we-welded. Ngeshwa, ayikho-usayizi owodwa ofanele - sonke isixazululo sokukhethwa kokuklama kwethempulethi. Eminye imiklamo isebenza kangcono nge-asches ehlukile ye-solder, izinhlobo ze-flux, noma ze-PCB. Kungathatha isivivinyo nephutha lokuthola ukukhetha kohlobo oluthile lwebhodi.

Ukuthola ngempumelelo ukwakheka kwethempulethi efanele kudinga inqubo enhle yokuhlola. Abakhiqizi kumele bathole indlela yokulinganisa futhi bahlaziye umphumela wokwakhiwa kwamafomu kuma-voids.

Indlela ethembekile yokwenza lokhu ukudala i-batch yama-PCBS enomklamo othile wethempulethi bese uyihlobisa kahle. Izifanekiso eziningana ezahlukahlukene zisetshenziselwa ukwenza lokhu. Ukuhlolwa kufanele kuveze ukuthi yimiphi imiklamo yamafomu inenombolo ephakathi yezimbobo zombizi.

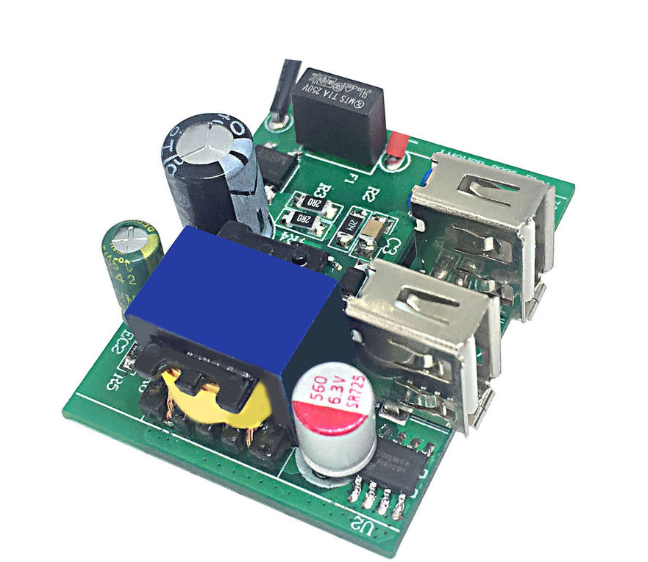

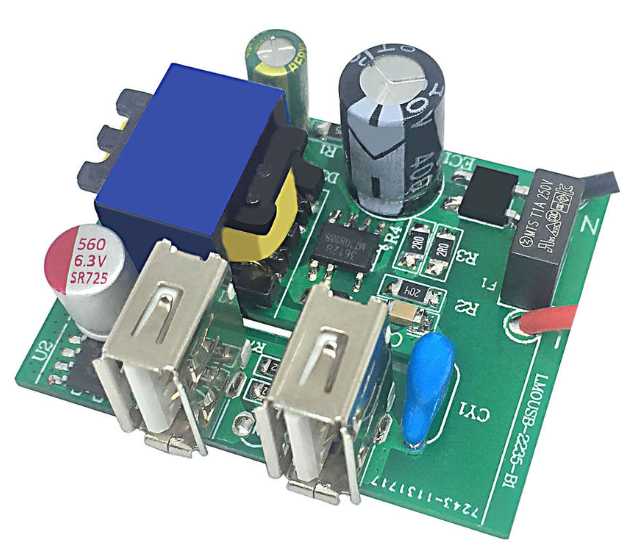

Ithuluzi elibalulekile kwinqubo yokuhlola ngumshini we-X-ray. I-X-ray ingenye yezindlela zokuthola izikhala ezinama-welded futhi ziwusizo ikakhulukazi lapho zisebenzelana nama-PCS amancane, agcwele phama. Ukuba nomshini olula we-X-ray kuzokwenza inqubo yokuhlola ibe lula kakhulu futhi isebenze kahle.

5.

Ngaphezu kobukhali bencanyana, ijubane lokumba libuye ibe nomthelela omkhulu kwikhwalithi yeplatiti. Uma ijubane elincanyana liphezulu kakhulu, lizonciphisa ukunemba futhi likhulise amathuba okubakwa kabusha kwemfucumfucu. Ijubane lokumba eliphakeme lingakhulisa ngisho nengozi yokuqhekeka kwe-PCB, ukusongela ubuqotho bezinhlekelele.

Uma izimbobo eziku-coatis zisavamile ngemuva kokucipha noma ukuguqula kancane, zama ukunciphisa inani lokumba. Ijubane elincane livumela isikhathi esithe xaxa sokwakha, ukuhlanza ngezimbobo.

Khumbula ukuthi izindlela zokukhiqiza zendabuko akuyona inketho namuhla. Uma ukusebenza kahle kucatshangelwa ekushayeleni amazinga okumba aphezulu, ukuphrinta kwe-3D kungaba ukukhetha okuhle. Ama-PC ebha aphrintiwe akhiqizwa kahle kunezindlela zendabuko, kepha ngokunemba okufanayo noma okuphezulu. Ukukhetha i-PCB ephrintiwe ye-3D kungenzeka kungafuneki ukugaya ngezimbobo nhlobo.

6.I-Stick to high quar solder anamathisela

Kungokwemvelo ukubheka izindlela zokonga imali kwinqubo yokukhiqiza ye-PCB. Ngeshwa, ukuthenga i-solde eshibhile noma ephansi ye-solde kungakhulisa amathuba okuba akha ama-wices we-weld.

Izakhiwo zamakhemikhali zezinhlobo ezahlukahlukene zokunameka umthengisi zithinta ukusebenza kwazo kanye nendlela abaxhumana ngayo ne-PCB ngesikhathi senqubo ye-Reflux. Isibonelo, usebenzisa i-asches solder engaqukethe ukuhola kungancipha ngesikhathi sokupholisa.

Ukukhetha i-Asches ephezulu ye-solde idinga ukuthi uqonde izidingo ze-PCB kanye nethempulethi esetshenzisiwe. I-Swerer Soler Asteas kuzoba nzima ukungena kwithempulethi nge-aperture encane.

Kungaba usizo ukuvivinya ama-pastes ahlukene we-soler ngasikhathi sinye njengokuhlola izifanekiso ezahlukahlukene. Ukugcizelelwa kufakwa ekusebenziseni umthetho webhola elihlanu ukuguqula usayizi we-template aperture ukuze unamathisele we-solder alinganise ithempulethi. Umthetho uthi abakhiqizi bazosebenzisa amafomu nge-Apertures edingekayo ukuze balingane namabhola amahlanu anama-solde. Lo mqondo wenza lula inqubo yokwakha ukumiswa okuhlukile kwethempulethi yethempulethi yokuhlola.

I-7.restuce solder unamathisele oxidation

I-oxidation of sorder paste ivame ukwenzeka lapho kunomoya omningi kakhulu noma umswakama osendaweni yokukhiqiza. I-oxidation ngokwayo inyusa amathuba okuba vele ama-voids akha, futhi futhi aphakamisa ukuthi umoya owedlulele noma umswakama uphinde unyuse ubungozi be-voids. Ukuxazulula kanye nokunciphisa i-oxidation kusiza ukuvikela izikhala ekwakheni futhi kuthuthukise ikhwalithi ye-PCB.

Okokuqala hlola uhlobo lwe-solder paste esetshenzisiwe. Ukunameka kwe-solluble ye-water-soluble kuthambekele kwi-oxidation ikakhulukazi. Ngaphezu kwalokho, i-flux enganele ikhulisa ubungozi be-oxidation. Vele, i-Flux eningi nayo nayo iyinkinga, ngakho-ke abakhiqizi kumele bathole ibhalansi. Kodwa-ke, uma kwenzeka i-oxidation, ukukhulisa inani le-flux ngokuvamile kungaxazulula inkinga.

Abakhiqizi be-PCB bangathatha izinyathelo eziningi ukuvikela izimbobo ze-welding emikhiqizweni kagesi. Ama-voids athinta ukuthembeka, ukusebenza nekhwalithi. Ngenhlanhla ngenhlanhla, ukunciphisa amathuba okuba vele ama-voids akha nje akulula njengokushintsha umdwebo we-solder noma usebenzisa idizayini entsha ye-stencil.

Usebenzisa indlela yokuhlola ukuhlola, noma yimuphi umenzi angathola futhi abhekane nembangela yezimpande ze-voids in Reflux kanye nezinqubo zokufaka ama-plating.