Kunezinhlobo eziningi zamabhodi wesifunda we-PCB emakethe, futhi kunzima ukuhlukanisa phakathi kwekhwalithi enhle nembi. Mayelana nalokhu, nazi izindlela ezimbalwa zokuhlonza ikhwalithi yamabhodi wesifunda we-PCB.

Ukwahlulela ngokubukeka

1. Ukubukeka kwe-weld seam

Njengoba kunezingxenye eziningi ebhodini lesifunda le-PCB, uma i-welding ingalungile, izingxenye zebhodi lesifunda zizowa kalula, zithinte kakhulu izinga lokushisela nokubukeka kwebhodi lesifunda, ngakho-ke kubaluleke kakhulu ukuba ne-welding eqinile.

2. Imithetho ejwayelekile yobukhulu nokushuba

Njengoba amabhodi esekethe e-PCB enobukhulu obuhlukile uma kuqhathaniswa namabhodi wesekethe ajwayelekile, abasebenzisi bangakala futhi bahlole ngokuya ngezidingo zabo.

3. Ukukhanya nombala

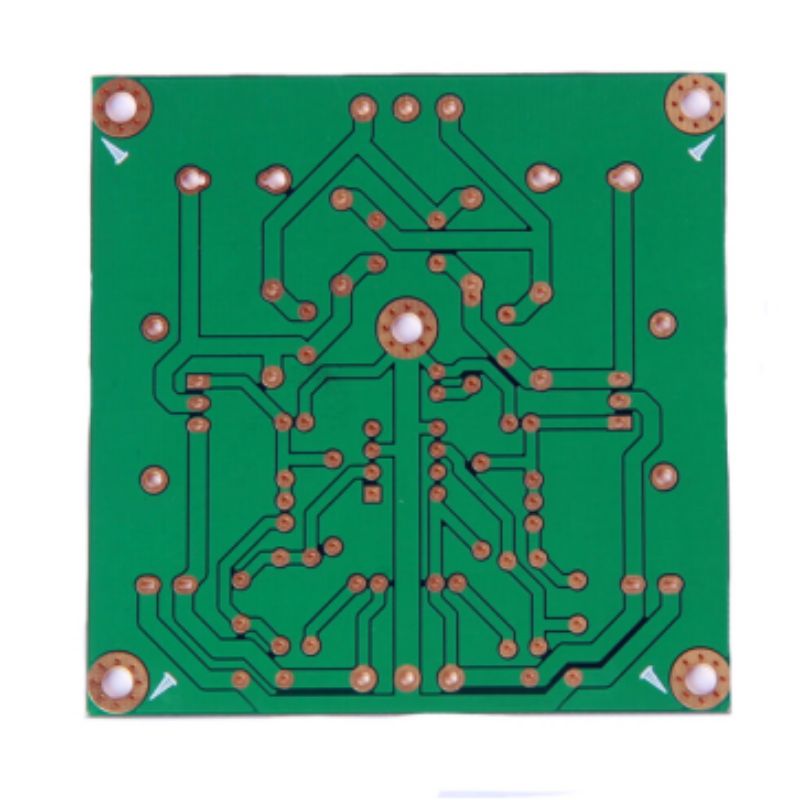

Ngokuvamile ibhodi lesekhethi ye-PCB yangaphandle imbozwa ngoyinki wokufakwa ngaphakathi. Uma umbala webhodi ungakhanyi futhi kune-inki encane, kusho ukuthi ibhodi lokufakelwa ngokwayo alilungile.

Ukwahlulela okuvela ku-plate material

1. Ikhadibhodi ye-HB evamile ishibhile futhi kulula ukuyonakalisa nokuphuka. Ingenziwa kuphela iphaneli eyodwa. Ingxenye engaphezulu inombala ophuzi omnyama futhi inephunga elicasulayo. I-copper coating ilukhuni futhi incane.

2. Amabhodi e-Single-side 94V0 kanye ne-CEM-1 abiza kakhulu kunekhadibhodi. Umbala wengxenye engaphezulu uphuzi ngokukhanyayo. Zisetshenziselwa ikakhulukazi amabhodi ezimboni kanye namabhodi amandla anezidingo zokuvikela umlilo.

3. Ibhodi le-Fiberglass linezindleko eziphakeme, amandla amahle, futhi liluhlaza nhlangothi zombili. Ngokuyisisekelo, amabhodi amaningi wesifunda we-PCB enziwe ngale nto. I-copper coating ingaba nembe kakhulu futhi ibe yinhle, kodwa ibhodi leyunithi linzima kakhulu. Kungakhathaliseki ukuthi imuphi umbala kayinki ophrintwe ebhodini lesekethe le-PCB, kufanele libe bushelelezi futhi libe sicaba, futhi akumele kube nemigqa engamanga, ithusi eliveziwe noma elibhayizayo.