Ukuqamba noma iyiphi i-PCB kuyinselele, ikakhulukazi njengoba amadivaysi ekhula futhi incane. Idizayini ephezulu ye-PCB iyinkimbinkimbi kakhulu ngoba inazo zonke izithiyo ezifanayo futhi idinga isethi eyengeziwe yezinto ezihlukile okufanele zicatshangelwe.

Ochwepheshe babikezela ukuthi isidingo samadivayisi anamandla kungenzeka sikhuphuke ukufezekisa amazinga okukhula wonyaka akhuphukayo we-Industrial Iot ngo-2030. Nazi izinyathelo eziyisikhombisa zokwenza kahle i-PCB design ku-Elektroniki yamanje yalo mkhuba.

1.QEQESHA usayizi owenele wekhebula

Usayizi womugqa ungomunye wokucatshangelwa okubaluleke kakhulu kwedizayini ye-PCBS ephezulu yamanje. I-Wiring ye-Copper iye yavumelana ne-miniaturised ukuthola ama-compact design amaningi, kepha lokhu akusebenzi ngemisinga ephakeme. Isigaba esincane sesiphambano singaholela ekulahlekelweni kwamandla ngokuhlanza ukushisa, ngakho-ke kudingeka usayizi omkhulu wethrekhi.

Ungashintsha indawo yesigaba sesigaba socingo ngokulungisa izinto ezimbili: ububanzi bocingo nobukhulu bethusi. Ukulinganisa lezi ezimbili kuyisihluthulelo sokwehlisa ukusetshenziswa kwamandla nokugcina usayizi omuhle we-PCB.

Sebenzisa i-PCB Line Worth Calculator ukuze ufunde ukuthi yikuphi ububanzi nobukhulu obusekela uhlobo lwamanje oludingekayo kudivayisi yakho. Lapho usebenzisa la mathuluzi, qaphela ukuklama usayizi we-wiring ukusekela amasondo aphezulu kunokwenza okudingayo.

Ukubekwa kwengxenye ye-2.Rethink

Isakhiwo sengxenye kungenye yezinto ezibalulekile ku-PCB yamanje ye-PCB. Ama-Mosfets kanye nezinto ezifanayo zikhiqiza ukushisa okuningi, ngakho-ke kubalulekile ukuzigcina zihlukaniswe namanye amabala ashisayo noma anozwela lokushisa ngangokunokwenzeka. Lokhu akulula ngaso sonke isikhathi lapho ubhekene nezici zefomu encishisiwe.

Ama-amplifiers nabaguquli kufanele bagcinwe ebangeni elifanele kusuka kuma-mosets nezinye izinto zokushisa. Ngenkathi kungahle kulingeze ukugcina indawo ephezulu yamandla emaphethelweni, lokhu akuvumeli ukusatshalaliswa kwamazinga okushisa okufanayo. Esikhundleni salokho, zibekwe emigqeni eqondile ngaphesheya kwebhodi ukuze zigcine amandla, okwenza ukushisa kube ngaphezulu.

Ngokusondela ezindaweni ezinethonya kakhulu kuqala, kulula ukunquma izingxenye ezifanele. Okokuqala, nquma indawo efanelekile yezinto zokushisa okuphezulu. Lapho usuyazi ukuthi ungazibeka kuphi, ungasebenzisa ukuphumula ukugcwalisa izikhala.

3.Aptimize Ukuphathwa Kokushisa Ukushisa

Ngokufanayo, ama-PCs aphezulu aphezulu nawo adinga ukuphathwa ngokucophelela okushisayo. Okwezicelo eziningi, lokhu kusho ukugcina izinga lokushisa langaphakathi ngaphansi kwama-degree angama-130 ama-Celsius okushisa kwengilazi okushisa kwe-FR4 Laminates. Ukulungiselela ukubekwa kwengxenye kuzosiza, kepha izinyathelo zakho zokunciphisa ukushisa kufanele zime lapho.

Ukupholisa ukuqina kwemvelo kunganele kuma-PCBS amancane wabathengi abathengi, kepha kungenzeka ukuthi akwanele ukusetshenziswa kwamandla aphezulu. Ama-radiator mehendi angadingeka. Ukupholisa okusebenzayo okufana nabalandeli noma amasistimu wokupholisa uketshezi azungeze ama-mosfets nawo asiza. Kodwa-ke, eminye imiklamo yedivaysi kungenzeka ingabi nkulu ngokwanele ukuze kuhlaliswe ama-radiator wendabuko noma ukupholisa okusebenzayo.

Nge-PCS encane kodwa ephezulu yokusebenza okuphezulu, ukuhlukaniswa kokushisa ngokusebenzisa izimbobo kuyindlela ewusizo. Insimbi ephethe kakhulu enochungechunge lwezimbobo ezithululelwe izosusa ukushisa ezivela kuma-moset noma izingxenye ezifanayo ngaphambi kokuthi ifinyelele ezindaweni ezibucayi kakhulu.

4.Sebenzisa izinto ezifanele

Ukukhethwa kwezinto ezibonakalayo kuzoba yinzuzo enkulu lapho ulungiselela ukuphathwa okushisayo kanye nokuqinisekisa ukuthi izakhi zingamelana nemikhuba ephezulu. Lokhu kusebenza kwizakhi ze-PCB kanye nezindawo zokubopha.

Yize u-FR4 esetshenziswa kakhulu, akusona isikhathi esingcono kakhulu semiklamo ye-PCB yamanje. Ama-PCB wensimbi-core kungenzeka abe ekahle ngoba alinganisela ukufakwa kanye nokusebenza kwezindleko zezigatshana ezifana ne-FR4 ngamandla okushisa okushisa kakhulu. Ngenye indlela, abanye abakhiqizi benza ama-laminate avikelekile avikelekile ongase ucabangele.

Futhi, kufanele usebenzise kuphela izingxenye ngamanani aphezulu wokumelana okushisayo. Kwesinye isikhathi, lokhu kusho ukukhetha izinto ezivimbela ukushisa okwengeziwe, kanti kwezinye izimo kusho ukusebenzisa izakhi ezinkulu zezinto ezifanayo. Yikuphi ukukhetha okungcono kuncike kusayizi wakho we-PCB, isabelomali, kanye nabahlinzeki abakhona.

5.Izitholela inqubo yokulawula ikhwalithi

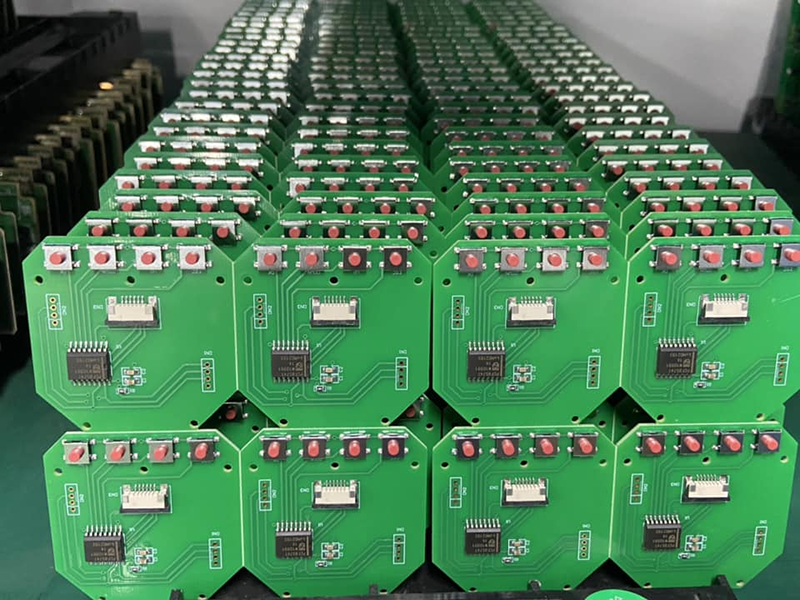

Ukwethembeka kwama-PCs aphezulu aphezulu nakho kuyindaba yokuthola amaphutha ekukhiqizweni. Uma inqubo yokukhiqiza ingenakuthola futhi ibhekane nezici ezingemuva kokuhlehlisa izinzuzo zayo, khona-ke izinqumo ezingenhla zokuklama ngeke zivuse ukuthuthuka okuningi. Amasheke aphezulu athembekile wekhwalithi yama-prototype ama-iterations nawo abalulekile.

Usebenzisa amathuluzi afanele ukuhlola ikhwalithi ye-PCB ingenye yokucatshangelwa okubaluleke kakhulu ensimini. Abalingisi be-Digital Optical njengezifanekiso nezindlela zokuphuma zendabuko izindlela zokwelula futhi bahlanekezela ngokuhamba kwesikhathi, bavimbela ukuthembeka kwabo. Kufanele futhi ubheke amathuluzi okulula ukushintshanisa ukunciphisa ingozi yephutha lomuntu.

Kungakhathalekile ukuthi izindlela ezithile namasu owasebenzisayo, ukulandelela konke ukulimala kubalulekile. Ngokuhamba kwesikhathi, le datha ingaveza ukuthambekela kokuvela kwezinkinga, ukuhlinzeka ngezinguquko ezithembekile ze-PCB.

6.

Isici esifanayo kodwa esivame ukunganakwa ekwakhiweni kwe-PCB ephezulu kakhulu kuqinisekisa kalula ukukhiqizwa. Uma amaphutha okukhiqiza evame kakhulu ukuthi idivaysi ingaqabuki ihlangabezana nezincazelo ephepheni, akunandaba ukuthi i-PCB ithembekile kangakanani ngombono.

Isixazululo ukugwema ukwakheka okuyinkimbinkimbi noma okuyinkimbinkimbi kakhulu ngangokunokwenzeka. Lapho uklama ama-PCB aphezulu aphezulu, gcina inqubo yakho yokukhiqiza engqondweni, ecabanga ukuthi ukugeleza kanjani kungaba ukuwathela kanjani nokuthi yiziphi izinkinga ezingase ziphakame. Kulula ungenza imikhiqizo engenaphutha, izonokwethenjwa ngokwengeziwe.

Lesi sinyathelo sidinga ukubambisana eduze nababambiqhaza abakhiqizayo. Uma ungaphathanga ukukhiqiza ngaphakathi endlini, faka ozakwethu bokukhiqiza esigabeni Design ukuze uthole okokufaka kwabo ngezinkinga ezingaba khona.

7.Sebenzisa ubuchwepheshe ukuze kusizakale

Amasu amasha wokuhlela nokukhiqiza angenza ukulinganisa lokhu kube lula. Ukuphrinta kwe-3D kwethula ukuguquguquka okwengeziwe ukuguquguquka kokusekelwa kwezakhiwo eziyinkimbinkimbi ze-PCB ngaphandle kwamaphutha wokukhiqiza. Ukucaciswa kwayo futhi kukuvumela ukuthi uqinisekise ukuthi i-wiring yethusi ilandela ijika kunokuba i-angle efanelekile yokunciphisa ubude bayo futhi inciphise ukusetshenziswa kwamandla

I-Artificial Intelligence kungenye ubuchwepheshe obufanele ukuphenya. Amathuluzi we-AI PCB angabeka izingxenye ngokuzenzakalelayo noma aqokomise izinkinga zokuklama ezingaba khona ukuvikela amaphutha ukuthi avele emhlabeni wangempela. Izisombululo ezifanayo zingalingisa izindawo ezahlukahlukene zokuhlola ukuze zihlole ukusebenza kwama-PCB ngaphambi kokukhiqiza ama-prototypes abonakalayo.

Idizayini ephezulu ye-PCB idinga ukuqapha

Ukuqamba i-PCB ethembekile yamanje akulula, kepha akunakwenzeka. Ukulandela lezi zinyathelo eziyisikhombisa kuzokusiza ukuthi wenze kahle inqubo yakho yokuqamba ukudala amadivayisi aphezulu anamandla aphezulu.

Njengoba i-inthanethi yezimboni yezinto ikhula, lokhu kucatshangelwa kuyobaluleka ngokwengeziwe. Ukuwabamba manje kuzoba yisihluthulelo sokuqhubeka kwempumelelo ngokuzayo.