Ukufakwa uphawu kwe-electroplated hole kuyindlela ephrintiwe ephrintiwe ephrintiwe inqubo yokukhiqiza ukugcwalisa nokubeka uphawu ngezimbobo (ngokusebenzisa izimbobo) ukuthuthukisa amandla kagesi nokuvikelwa. Enqubweni yokukhiqiza ye-Circuity Board ephrintiwe, umgodi we-pass-pay isiteshi esisetshenziselwa ukuxhuma izingqimba zesekethe ezahlukahlukene. Inhloso yokuvalwa kwangaphakathi kwe-electroplating ukwenza udonga lwangaphakathi lwe-hole lugcwele izinto ezisebenzayo ngokwakha ungqimba lwezinto zensimbi noma zokuphamba kwezinto ezibonakalayo ngaphakathi kwe-hole, ngaleyo ndlela ethuthukisa umphumela ongcono wokubekwa uphawu.

1.Inqubo ye-electroplating ye-electroplating ye-electroplating ye-electroplating ilethe izinzuzo eziningi kwinqubo yokukhiqiza umkhiqizo:

a) Ukwenza ngcono ukuthembeka kwesifunda: Inqubo yokuvalwa kwe-Electroity Searing ye-Electroing ye-Electroing ingavala izimbobo ezimfushane futhi ivikele umjikelezo ofushane kagesi phakathi kwezendlalelo zensimbi ebhodini lezesekeli. Lokhu kusiza ukuthuthukisa ukwethenjwa nokuqina kweBhodi futhi kunciphisa ingozi yokwehluleka kwesifunda nomonakalo

b) Ngcono ukusebenza kwesekethe; ngenqubo yokuvalwa kokuvalwa kwe-electtroplating, ukuxhumana okungcono kwesizungeza kanye nokusebenza kukagesi kungatholakala. I-Electroplate Filling Hole inganikeza ukuxhumana okuzinzile futhi okuthembekile kwesekethe, kunciphise inkinga yokulahleka kwesiginali nokungaziphathi kahle, ngakho-ke ukuthuthukisa amandla okusebenza kwesekethe nokukhiqiza.

c) Thuthukisa ikhwalithi ye-welding: Inqubo yokuvalwa kwe-Electroplating ye-Electroplating ye-Electroplating nayo ingathuthukisa ikhwalithi ye-welding. Inqubo yokuvalwa uphawu ingadala indawo eyisicaba, ebushelelezi ngaphakathi komgodi, inikeze isisekelo esingcono sokufudumala. Lokhu kungathuthukisa ukwethenjwa namandla okushisela futhi kunciphise ukwenzeka kwezinkinga ze-welding kanye nezinkinga ezibandayo ze-welding.

d) Qinisa amandla emishini: Inqubo yokubekwa uphawu nge-electroplating ingathuthukisa amandla okusebenza kanye nokuqina kweBhodi Yesekethe. Ukugcwalisa izimbobo kungakhuphula ubukhulu nokuqina kwebhodi yesekethe, kuthuthukise ukumelana kwayo kokugoba nokudlidliza, nokunciphisa ubungozi bokulimala kwemishini kanye nokuqhekeka ngesikhathi sokusebenzisa.

e) Umhlangano olula nokufakwa: Inqubo yokuvalwa kwe-Electroquity Board Electroplaing ingenza umhlangano kanye nokufaka inqubo ibe lula futhi isebenze kahle. Ukugcwalisa izimbobo kuhlinzeka ngendawo ezinzile namaphoyinti okuxhuma, okwenza umhlangano kube lula futhi kunembe kakhudlwana. Ngaphezu kwalokho, ukubekwa uphawu kwe-electroplated hole kuhlinzeka ngokuvikelwa okungcono futhi kunciphisa ukulimala kanye nokulahleka kwezakhi ngesikhathi sokufakwa.

Ngokuvamile, inqubo ye-Electroquity Boating Searing Search ingathuthukisa ukuthembeka kwesifunda, yenza ngcono ukusebenza kwesekethe, ithuthukise ikhwalithi ye-welding, qinisa amandla omshini, futhi yenza umhlangano wokuhlanganisa nokufaka. Lezi zinzuzo zingathuthukisa kakhulu ikhwalithi yomkhiqizo kanye nokwethenjwa, ngenkathi kunciphisa ubungozi kanye nezindleko kwinqubo yokukhiqiza

2.Ngani i-Electrobing Board Lectroplating Searing Process inezinzuzo eziningi, kukhona nezinye izingozi noma ukushiyeka, okubandakanya okulandelayo:

f) Izindleko ezandisiwe: Inqubo yokubopha imbobo yeBhodi idinga izinqubo ezengeziwe nezinto zokwakha kanye namakhemikhali asetshenziswa kwinqubo yokuqoqa. Lokhu kungakhulisa izindleko zokukhiqiza futhi kube nomthelela emsoco wonke womkhiqizo

g) Ukwethenjwa kwesikhathi eside: yize inqubo yokubekwa uphawu nge-electroplating ingathuthukisa ukuthembeka kwebhodi yesekethe, esimweni sezemvelo, impahla yokugcwalisa kanye nokukhonjwa kungathintwa yizici ezinjengokukhishwa okubandayo, umswakama, ukugcwala nokunye. Lokhu kungaholela ezintweni ezikhululekile zosizi, ziwe, noma zilimaze ukugcwala, zinciphisa ukuthembeka kweBhodi

h) Ubunzima be-3process: Inqubo yokuvalwa kwe-Electroplating ye-Electroplating Bloating iyinkimbinkimbi kakhulu kunenqubo evamile. Kubandakanya ukulawulwa kwezinyathelo eziningi kanye namapharamitha anjengokulungiselela umgodi, ukugcwalisa Ukukhethwa kwezinto ezibonakalayo nokwakha, Ukulawulwa kwenqubo ye-electroplating, njll. Lokhu kungadinga amakhono enqubo ephezulu kanye nemishini yokuqinisekisa ukunemba kwenqubo nokuqina.

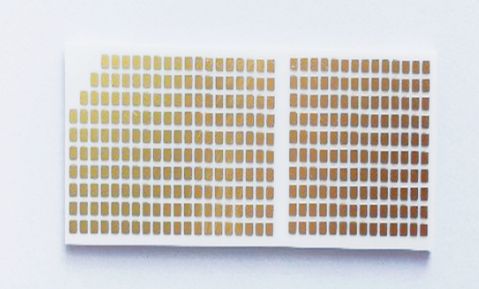

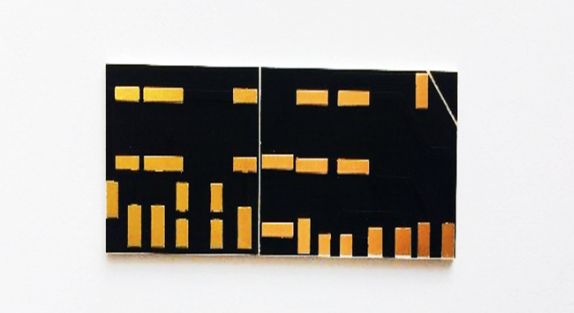

i) Khulisa inqubo: Khulisa inqubo yokuvalwa kweamboni, futhi wandise ifilimu elivinjelwe ngezimbobo ezinkulu kancane ukuze uqinisekise umphumela wokubekwa uphawu. Ngemuva kokufaka uphawu emgodini, kuyadingeka ukufonela ithusi, ukugaya, ukucwaswa kanye nezinye izinyathelo zokuqinisekisa ukuthobeka kobuso bendawo.

j) Umthelela Wezemvelo: Amakhemikhali asetshenziswa kwinqubo yokubekwa uphawu nge-electtroplating angaba nomthelela othile emvelweni. Isibonelo, amanzi amdaka kanye nodoti owuketshezi kungenzeka akhiqizwe ngesikhathi sokulinganisa, okudinga ukwelashwa okufanele nokwelashwa okufanele. Ngaphezu kwalokho, kungenzeka kube nezinto eziyingozi zemvelo ezintweni zokugcwalisa ezidinga ukuphathwa kahle futhi zilahlwe.

Lapho ucubungula i-Electrong Board Board Searing inqubo, kuyadingeka ukuze ubheke ngokugcwele lezi zingozi noma ukushiyeka, futhi unesisindo esihle ngokwezidingo ezithile nezimo zohlelo lokusebenza. Lapho usebenzisa inqubo, ukulawulwa kwekhwalithi efanelekile kanye nezindlela zokulawulwa kwezemvelo kubalulekile ukuze uqinisekise imiphumela yenqubo engcono kakhulu kanye nokwethenjwa komkhiqizo.

Amazinga we-Ocraunce

Ngokusho kwe-Standard: IPC-600-J3.3.20: I-Electroplated Copper Plug Plugcper (izimpumputhe futhi yangcwatshwa)

I-SAG ne-Bulge: Izidingo ze-Bulge (Bump) nokudangala (pit) ze-Micro-Pireck Micro-Toole zizonqunywa ngokuhlinzekwa kanye nokucindezelwa kwe-micro-hole ematasa yethusi. Imibhalo ethile yokuthengwa kwempahla yamakhasimende noma amazinga amakhasimende njengesisekelo sokwahlulela.