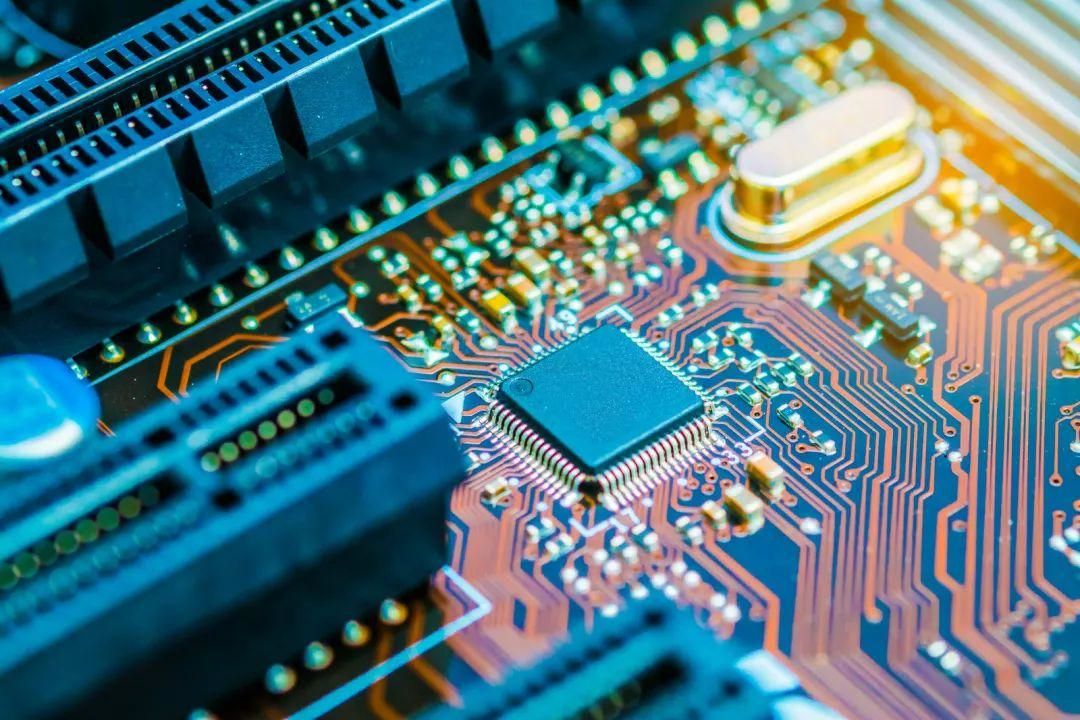

I-PCB Circuit Board kwinqubo yokukhiqiza, ivame ukuhlangana nezinkinga ezithile zenqubo, njenge-PCB Circuit Board wire off off Okubi (kuvame futhi ukuthi kuthiwa ukuphonsa i-Copper), kuthinte ikhwalithi yomkhiqizo). Izizathu ezivamile zePCB Circuit Board Prost zethu zimi ngokulandelayo:

Izici zenqubo yePCB Circuit Board Factors

I-1, i-Fopper Foil etching i-foil ye-Fopper ye-electrolytic esetshenzisiwe esetshenziswayo ngokuvamile i-galvanized ye-galvanized (ejwayele eyaziwa ngokuthi yi-foil ye-grey ye-gray)

2. Ukushayisana kwasendaweni kwenzeka kwinqubo ye-PCB, kanti nocingo lwethusi luhlukaniswe ne-substrate ngamandla angaphandle okwenziwa. Lesi sici sibonakalisa njengokuma kahle noma ukuma kwe-toring, ucingo olwehla luzoba nokuhlanekezela okusobala, noma ngendlela efanayo yophawu lwe-scratch / umthelela. Cwecwa engxenyeni embi yocingo yethusi ukuze ubone indawo ye-foil ye-Copper, ungabona umbala ojwayelekile we-foil foil, ngeke kube nokuguguleka okulungile oseceleni, amandla we-foil we-copper ajwayelekile.

I-3, i-PCB Circuit Design ayinengqondo, ngohlobo olubanzi lwe-Copper Foil lomugqa omncane kakhulu, luzobuye ibangele i-etching umugqa owedlulele kanye nethusi.

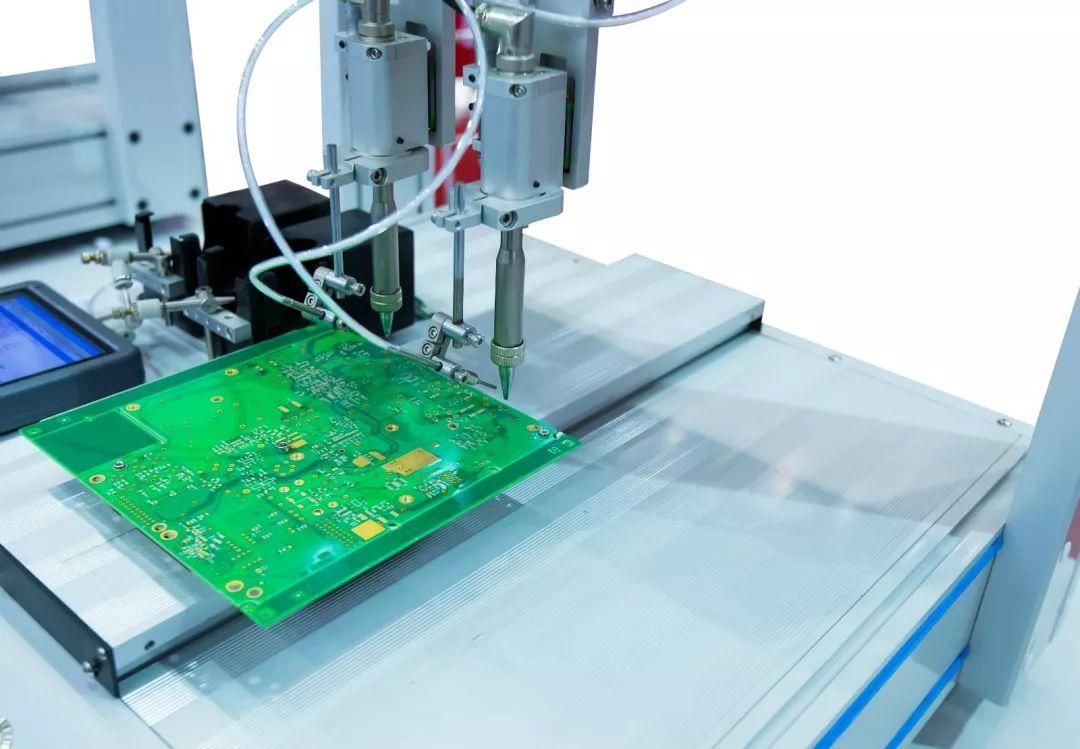

Inqubo ye-Laminate Process

Ngaphansi kwezimo ezijwayelekile, inqobo nje uma ucindezele kakhulu ingxenye yokushisa ephezulu ye-linate imizuzu engama-30, i-foil ye-post foil kanye nephepha eliphethwe ngokuyisisekelo ahlanganiswe ngokuphelele, ngakho-ke ukucindezela ngokuvamile ngeke kuthinte amandla okubopha. Kodwa-ke, kwinqubo ye-Lamia Fingleng kanye nokufakwa, uma ukungcoliswa kwe-PP noma ukungcoliswa kwe-PPPER foil Surface, kuzoholela kumandla anganele phakathi kwe-Folip ye-Fople, kepha amandla okulahleka kwe-Fopper eduzane nomugqa wokudonsa ngeke kube okungajwayelekile.

I-Laminate are

1, i-electrolytic evamile ye-electrolytic ye-electronic yimikhiqizo ye-galvanized noma yethusi, uma inani eliphakeme le-fool foil ukukhiqizwa kwe-plurwormics embonini ye-PCB, okuholela ekwenzeni umthelela wangaphandle. Lolu hlobo lwe-fooil ye-fooil ye-fooil embi yethusi (okungukuthi, indawo yokuxhumana ne-substrate) ngemuva kokuguguleka okusobala okusobala, kepha wonke umuntu wamandla we-post ail acwebezela.

2. Ukuqina okumpofu kwe-foil yethusi kanye ne-resin: amanye ama-lamin anezindawo ezikhethekile asetshenziswa manje, njenge-HTG Sysery, ngenxa yesakhiwo se-resin ehlukile, i-resin consective system, i-desin corsective system, ukusebenzisa i-foil ye-crosslinking ekhethekile kanye nomdlalo. Lapho ukukhiqizwa kwe-laminate kusetshenziswa i-foil ye-Copper kanye nohlelo lwe-resin akuhambelani, okuholela ekusetshenzisweni kwensimbi ye-foil yensimbi akwanele, i-plug-in nayo izovela nokuchithwa kwentambo okubi.

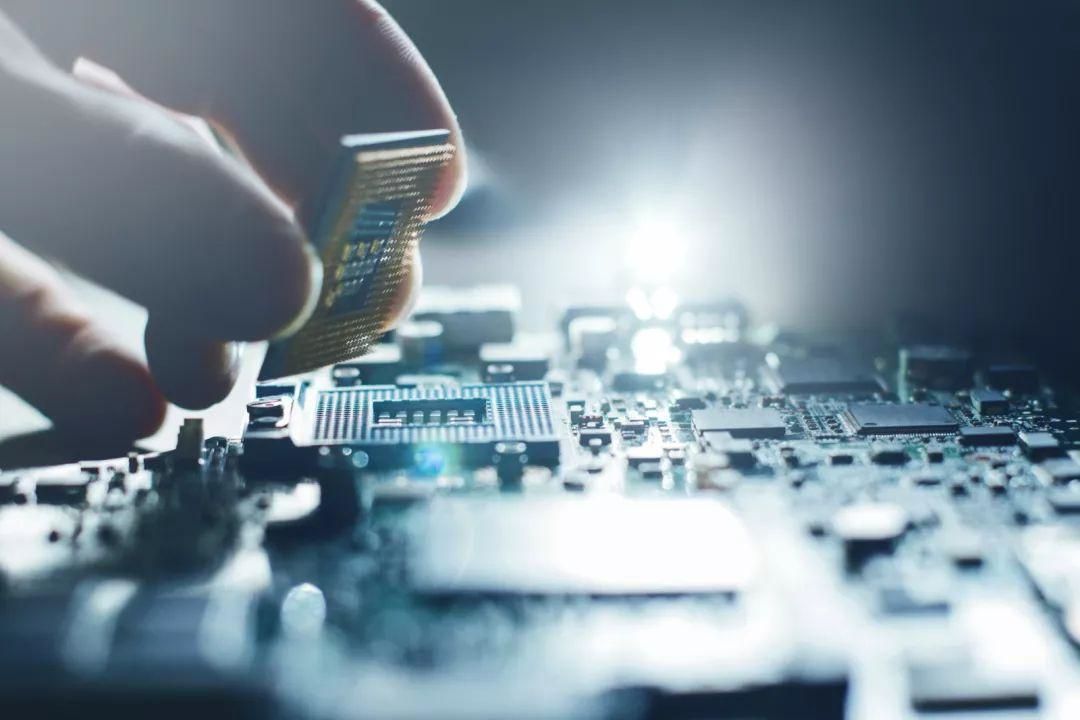

Ngaphezu kwalokho, kungenzeka ukuthi i-welding engafaneleki eklayenti iholela ekulahlekelweni kwepani ye-welding (ikakhulukazi amaphaneli angashadile, okushisa okusheshayo, ukushiyeka okushisa okusheshayo, amazinga okushisa we-welding aphezulu, akulula ukuwa):

● Ukuphindisela okuphindaphindiwe indawo izokwenqabela i-pad;

● izinga lokushisa eliphakeme le-soldering iron kulula ukuwela i-pad;

● Ingcindezi eningi kakhulu esetshenziselwa ikhanda lensimbi elungiselelwe pad futhi isikhathi eside kakhulu selding izovimba pad.