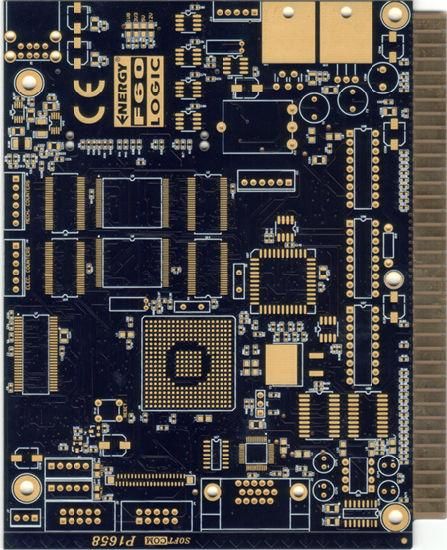

I-Copper coating, okungukuthi, indawo engenzi lutho ku-PCB isetshenziswa njengezinga lesisekelo, bese igcwaliswa ngethusi eliqinile, lezi zindawo zethusi zibizwa nangokuthi ukugcwaliswa kwethusi. Ukubaluleka kwe-copper coating ukunciphisa i-impedance yomhlabathi nokuthuthukisa ikhono lokulwa nokuphazamiseka. Yehlisa ukwehla kwamandla kagesi, uthuthukise ukusebenza kahle kwamandla; Ixhunywe nentambo yaphansi, indawo yeluphu nayo ingancishiswa. Futhi ngenjongo yokwenza ukushisela kwe-PCB ngangokunokwenzeka ngaphandle kokuguqulwa, abakhiqizi abaningi be-PCB bazophinde bafune ukuthi abaklami be-PCB bagcwalise indawo evulekile ye-PCB ngethusi noma ngocingo lomhlabathi onjengegridi, uma ithusi liphathwa ngendlela engafanele, ngeke kulahleke, kungakhathaliseki ukuthi ithusi “lihle kakhulu kunokubi” noma “libi kakhulu kunokuhle”?

Sonke siyazi ukuthi esimweni sokuvama okuphezulu, i-capacitance esabalalisiwe yezintambo ebhodini lesifunda eliphrintiwe izosebenza, lapho ubude bukhulu kuno-1/20 we-wavelength ehambisanayo yefrikhwensi yomsindo, kuzoba nomphumela we-antenna, futhi umsindo uzokhishwa ngaphandle nge-wiring, uma kukhona i-copper embi esekelwe phansi ku-PCB, i-copper coating isibe yithuluzi lokusabalalisa umsindo, ngakho-ke, kumjikelezo we-high frequency, Ungacabangi ukuthi indawo ethile ucingo oluphansi luxhunywe phansi, okuyinto "intambo yomhlabathi", futhi kufanele ibe ngaphansi kwezikhala ezingaphansi kuka-λ/20, izimbobo zokubhoboza ku-wiring, futhi indiza ephansi yebhodi le-multilayer "isekelwe kahle". Uma i-copper yethusi iphathwa kahle, ukugqoka kwethusi akugcini nje ukwandisa okwamanje, kodwa futhi kudlala indima emibili yokuphazanyiswa kokuvikela.

Ngokuvamile kunezindlela ezimbili eziyisisekelo zokumboza ngethusi, okungukuthi, indawo enkulu yokumboza yethusi kanye ne-grid yethusi, futhi kuvame ukubuzwa ukuthi indawo enkulu yokumboza yethusi noma igridi yokumboza yethusi yinhle, akukuhle ukuhlanganisa. Kungani kunjalo? I-copper yendawo enkulu inendima embaxambili yokwandisa amandla amanje nokuvikela, kodwa indawo enkulu yokumboza yethusi, uma i-wave soldering ingaphezu kwamagagasi, ibhodi lingase litshekele phezulu, ngisho negwebu. Ngakho-ke, indawo enkulu enamathela zethusi, ngokuvamile evulekile Slots eziningana, ekudambiseni ucwecwe yethusi Foil, igridi elula zethusi enamathela ngokuyinhloko isivikelo umphumela, ukwandisa indima yamanje kuncishisiwe, ngokombono ukushabalalisa ukushisa, igridi inezinzuzo. (yehlisa indawo yokushisisa yethusi) futhi idlale indima ethile ekuvikeleni kazibuthe kagesi.

Kodwa kufanele kuphawulwe ukuthi igridi yakhiwa isiqondiso esintengayo somugqa, siyazi ukuthi kumjikelezo, ububanzi bomugqa we-frequency yokusebenza kwebhodi lesifunda buhambisana "nobude bukagesi" obuhambisanayo (usayizi wangempela ohlukaniswe imvamisa yokusebenza yefrikhwensi yedijithali ehambisanayo ingatholakala, bheka ngokukhethekile izincwadi ezifanele), lapho imvamisa yokusebenza ingephezulu kakhulu, Mhlawumbe indima yemigqa yegridi ayibonakali kahle, lapho ubude bukagesi kanye nomdlalo wemvamisa yokusebenza, kubi kakhulu, uzothola ukuthi isifunda asisebenzi kahle, yonke indawo ikhipha amasignali aphazamisa umsebenzi wesistimu. Ngakho-ke kozakwethu abasebenzisa igridi, ukusikisela kwami ukuthi ukhethe ngokuvumelana nomklamo webhodi lesifunda, futhi ungabambeli entweni eyodwa. Ngakho-ke, i-high frequency circuit ngokumelene nezidingo zokuphazanyiswa zegridi yezinhloso eziningi, isifunda se-frequency ephansi enesekhethi yamanje ephezulu kanye nokunye okuvame ukusetshenziswa okuphelele kwe-copper paving.