1. PCB ngokusebenzisa imbobo Plating

Kunezindlela eziningi zokwakha ungqimba lwe-plating oluhlangabezana nezidingo odongeni lwembobo ye-substrate. Lokhu kubizwa ngokuthi i-hole wall activation ezinhlelweni zezimboni. Abakhiqizi bayo bebhodi le-PCB basebenzisa amathangi amaningi okugcina amaphakathi ohlelweni lokukhiqiza. Ithangi ngalinye lokugcina Ithangi linezidingo zalo zokulawula nokulilungisa. I-Phry-hole electroplating iyinqubo yokukhiqiza edingekayo yenqubo yokumba. Lapho i-drill bit ibhoboza i-foil yethusi kanye ne-substrate engezansi, ukushisa okukhiqiziwe kuncibilikisa inhlaka yokwenziwa evikelayo eyenza isisekelo sama-substrates amaningi, inhlaka encibilikisiwe nezinye izingcezu zokumba Ifakwa eduze kwembobo futhi imbozwe embobeni esanda kuvulwa. odongeni ku-foil yethusi, okuyinto empeleni eyingozi ku-plating surface elandelayo.

I-resin encibilikisiwe izophinde ishiye ungqimba lwe-axis eshisayo odongeni lwembobo ye-substrate, ekhombisa ukunamathela okungekuhle kuma-activator amaningi, okudinga ukuthuthukiswa kwekilasi lamasu afana nokususwa kwamabala kanye ne-etchback chemistry. Enye indlela efaneleka kakhulu kumfuziselo wamabhodi esekethe aphrintiwe ukusebenzisa uyinki oklanywe ngokukhethekile one-viscosity ukuze kwakhe ukunamathela okunamathelayo kakhulu nokuqhuba kahle odongeni lwangaphakathi lwembobo ngayinye. Ngale ndlela, asikho isidingo sokusebenzisa izinqubo zokwelashwa kwamakhemikhali amaningi, isinyathelo esisodwa kuphela sesicelo, esilandelwa ukuphulukiswa okushisayo, singenza ukugqoka okuqhubekayo ngaphakathi kwazo zonke izindonga zembobo, kungenziwa ngokuqondile nge-electroplated ngaphandle kokwelashwa okwengeziwe. Lo uyinki uyinto esekelwe ku-resin enamathela ngokuqinile futhi ingaboshelwa kalula ezindongeni eziningi zembobo ezipholishelwe ngokushisa, ngaleyo ndlela isuse isinyathelo sokubuyela emuva.

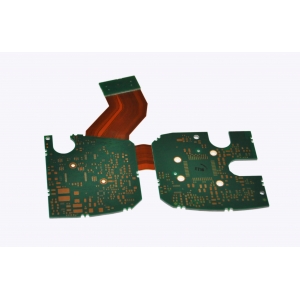

2. Uhlobo lokuxhumanisa lwe-reel olukhethayo

Izikhonkwane nezikhonkwane zezingxenye ze-elekthronikhi, njengezixhumi, amasekhethi ahlanganisiwe, ama-transistors, namabhodi e-FPCB aguquguqukayo, konke kuhlanganiswe ukuze kutholakale ukumelana okuhle kokuxhumana nokumelana nokugqwala. Le ndlela ye-electroplating ingaba ngesandla noma i-othomathikhi, futhi kubiza kakhulu ukukhetha iphinikhodi ngayinye ukuze ifakwe, ngakho-ke kufanele kusetshenziswe i-mass welding. Ngokuvamile, iziphetho ezimbili ze-foil yensimbi egoqelwe ekugqineni okudingekayo zishaywa, zihlanzwa ngezindlela zamakhemikhali noma zemishini, bese zikhethwa ngokukhetha njenge-nickel, igolide, isiliva, i-rhodium, inkinobho noma i-tin-nickel alloy, i-copper-nickel alloy , i-Nickel. -i-alloy yokuhola, njll yokucwenga okuqhubekayo. Endleleni ye-electroplating ye-plating ekhethiwe, okokuqala, ungqimba lwefilimu yokumelana lumbozwa engxenyeni yepuleti lensimbi yethusi elingadingi ukupuntshwa, futhi ingxenye ye-foil yethusi ekhethiwe kuphela efakwe.

3. I-Finger-plating

Insimbi eyivelakancane idinga ukunamathiselwa esixhunyweni sonqenqema lwebhodi, unqenqema lwebhodi oluphumayo noma umunwe oyigolide ukuze unikeze ukumelana okuphansi nokungagugi. Le ndlela ibizwa ngokuthi i-finger row plating noma ingxenye ephumela ngaphandle. Igolide livamise ukunameka koxhumene nabo abaphumele ngaphandle kwesixhumi sonqenqema nge-nickel plating ongqimbeni lwangaphakathi. Umunwe wegolide noma ingxenye ephumayo yonqenqema lwebhodi isebenzisa ubuchwepheshe bokucwenga bezandla noma obuzenzakalelayo. Njengamanje, ucwecwe lwegolide kupulaki lokuxhumana noma umunwe oyigolide lunamekwe ngogogo nomthofu , esikhundleni salokho izinkinobho ezipthiwe.

Inqubo imi kanje:

1. Hlikihla i-coating ukuze ususe ithini noma i-tin-lead enamathela ezintweni eziphumayo.

2. Hlanza ngamanzi okugeza.

3. Hlanza ngeziqhumane.

4. Ukwenza kusebenze kucwiliswe ku-10% we-sulfuric acid.

5. Ugqinsi lwe-nickel plating koxhumene nabo abaphumile buyi-4-5μm.

6. Geza futhi ususe amanzi amaminerali.

7. Ukwelashwa kwesixazululo sokungena kwegolide.

8. Ukucwecwa kwegolide.

9. Ukuhlanza.

10. Ukomisa.

4. Ukufakwa kwebhulashi

Kuyindlela ye-electrodeposition, futhi akuzona zonke izingxenye ezicwiliswa ku-electrolyte ngesikhathi senqubo ye-electroplating. Kule nqubo ye-electroplating, indawo elinganiselwe kuphela i-electroplated, futhi ayinawo umthelela kokunye. Imvamisa, izinsimbi ezingavamile zigqitshwa ezingxenyeni ezikhethiwe zebhodi lesifunda eliphrintiwe, njengezindawo ezifana nezixhumi zonqenqema lwebhodi. I-brush plating isetshenziswa kaningi lapho kulungiswa amabhodi esifunda semfucuza ezitolo ze-electronic assembly. Gcoba i-anode ekhethekile (i-anode engasebenzi ngamakhemikhali, njengegraphite) endaweni emuncayo (i-cotton swab) bese uyisebenzisela ukuletha isisombululo sokucwenga endaweni lapho kudingeka khona ukucwenga.

Fastline Circuits Co., Limited uchwepheshe: Umkhiqizi wokukhiqiza ibhodi lesifunda le-PCB, ekunikeza: Ukuhlolwa kwe-PCB, ibhodi lesistimu ye-batch, ibhodi le-PCB engu-1-34, ibhodi le-TG eliphakeme, ibhodi le-impedance, ibhodi le-HDI, ibhodi le-Rogers, Ukwakhiwa nokukhiqizwa kwamabhodi wesifunda we-PCB ahlukahlukene. izinqubo nezinto zokwakha ezinjengamabhodi e-microwave, amabhodi amafrikhwensi omsakazo, amabhodi e-radar, amabhodi e-foil yethusi aminyene, njll.