Ukudibanisa ucingo– indlela yokunyusela itshiphu kwiPCB

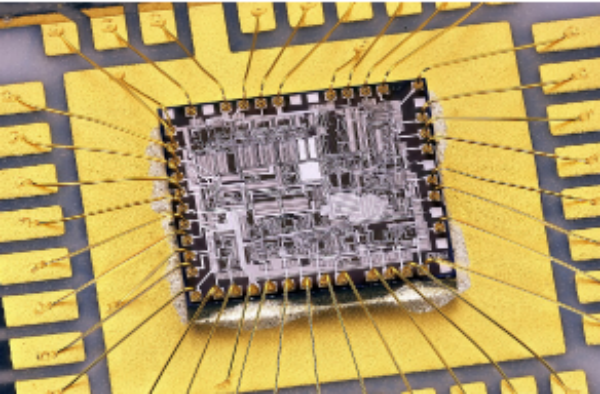

Kukho iitshiphusi ezingama-500 ukuya kwi-1,200 eziqhagamshelwe kwi-wafer nganye ngaphambi kokuphela kwenkqubo. Ukuze usebenzise ezi chips apho zifuneka khona, iwafer kufuneka isikwe kwiitshiphusi zomntu ngamnye kwaye emva koko iqhagamshelwe ngaphandle kwaye ikhanyise. Ngeli xesha, indlela yokudibanisa iingcingo (iindlela zokuhambisa izibonakaliso zombane) zibizwa ngokuba yi-wire bonding.

Izinto ze-wirebonding: igolide / i-aluminiyam / ubhedu

Izinto eziphathekayo ze-wirebonding zichongwa ngokuqwalasela ngokubanzi iiparitha ezahlukeneyo ze-welding kunye nokudibanisa kwindlela efanelekileyo kakhulu. Iiparamitha ekubhekiselwe kuzo apha zibandakanya imiba emininzi, kubandakanya uhlobo lwemveliso yesemiconductor, uhlobo lokupakishwa, ubungakanani bepadi, idiameter yentsimbi ekhokelayo, indlela yokuwelda, kunye nezalathi zokuthembeka ezinje ngokuqina kokuqina kunye nobude belothe yentsimbi. Izinto eziqhelekileyo zentsimbi ezikhokelayo ziquka igolide, i-aluminiyam kunye nobhedu. Phakathi kwabo, ucingo lwegolide lusetyenziswa kakhulu kwipakethe ye-semiconductor.

I-Gold Wire ine-conductivity elungileyo yombane, izinzile ngokwekhemikhali, kwaye inokumelana nokugqwala okuqinileyo. Nangona kunjalo, eyona nto ingathandekiyo yocingo lwe-aluminium, olwalusetyenziswa kakhulu kwiintsuku zokuqala, yayikukuba kwakulula ukugrumba. Ngaphezu koko, ukuqina kocingo lwegolide kunamandla, ngoko kunokwakheka kakuhle kwibhola kwi-primary bonding, kwaye inokwenza ngokufanelekileyo i-loop semicircular lead loop (Loop, ukusuka kwi-primary bonding ukuya kwi-secondary bonding) kwi-secondary bonding. imilo eyenziweyo).

Ucingo lweAluminiyam lunobubanzi obukhulu kunye nepitch enkulu kunocingo lwegolide. Ngoko ke, nangona ucingo lwegolide olucocekileyo lusetyenziselwa ukwenza i-loop loop, aluyi kuphuka, kodwa ucingo olucocekileyo lwe-aluminium luya kuphuka lula, ngoko luya kuxutywa kunye ne-silicon okanye i-magnesium ukwenza i-alloy. Ucingo lwe-aluminium lusetyenziswa ikakhulu kwipakethe yobushushu obuphezulu (njengeHermetic) okanye iindlela ze-ultrasonic apho ucingo lwegolide lungenakusetyenziswa.

Nangona ucingo lobhedu lunexabiso eliphantsi, ukuqina kwalo kuphezulu kakhulu. Ukuba ubunzima buphezulu kakhulu, akuyi kuba lula ukwenza ibhola, kwaye kukho imida emininzi xa kusenziwa iilophu ezikhokelayo. Ngaphezu koko, uxinzelelo kufuneka lusetyenziswe kwi-chip pad ngexesha lenkqubo yokudibanisa ibhola. Ukuba ubunzima buphezulu kakhulu, ukuqhekeka kuya kubonakala kwifilimu ephantsi kwepadi. Ukongezelela, kuya kubakho into ethi "peeling" apho i-pad layer edibeneyo idibanisa. Nangona kunjalo, ekubeni i-wiring yentsimbi ye-chip yenziwe ngobhedu, kukho umkhwa okhulayo wokusebenzisa ucingo lobhedu kule mihla. Ngokuqinisekileyo, ukuze unqobe ukusilela kocingo lobhedu, ngokuqhelekileyo luxutywe kunye nenani elincinci lezinye izinto zokwenza i-alloy kwaye zisetyenziswe.