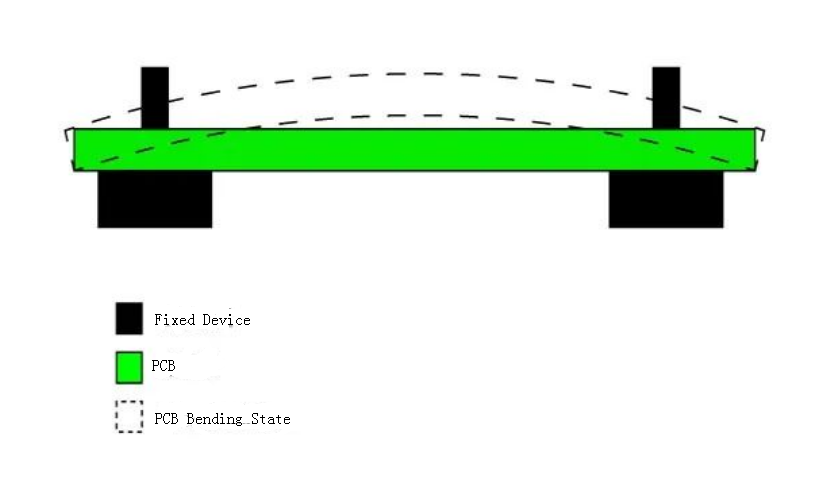

Ngapha koko, ukukholisa i-PCB kubhekisa ekugonyeni kweBhodi yeSiphaluka, ebhekisele kwiBhodi yeSevethi yasekuqaleni. Xa ifakwe kwi-desktop, iziphelo ezibini okanye phakathi kwebhodi zibonakala kancinci phezulu. Le phenomeno yaziwa ngokuba yi-PCB idle kwishishini.

Ifomula yokubala iMfazwe yeBhodi yeBhodi yeBhodi yeBhodi kunye neekona ezine zeBhodi yeSiphaluka phantsi kwaye zilinganisa ukuphakama kwe-arch embindini. Ifomula imi ngolu hlobo lulandelayo:

Imfazwe = ukuphakama kwe-arch / ubude be-PCB ende * 100%.

Umgangatho weBhodi yeShedshoni yeShishini: Ngokwe-IPC - 6012 (1996 i-odolo) Ngenxa yezakhono ezahlukeneyo zomzi-mveliso ngamnye, kukho umahluko othile kwiimfuno zolawulo lwemfazwe ye-PCB. NgeeBhodi zePakethi ye-1.6 yeBhodi eziPhambili eziPhakathiweyo, uninzi lwabavelisi beBhodi yeSekethe, uninzi lwabavelisi be-PCB balawula i-PCB yeMfazwe phakathi kwe-0.50.75%, iibhodi zebhodi, i-BMT, i-BMT, i-BMT, i-BMT, i-BMT, i-BMT yenkqubo yenkqubo ye-PCB ukuya kwi-0.3%.

Ungayiphepha njani imvume yeBhodi yeSiphaluka ngexesha leMveliso?

.

(2) Ibhodi ephambili yePCB yePCB kunye nephepha lokunyanga kufuneka lisebenzise iimveliso zomthengisi ofanayo;

.

Ungayithintela njani iBhodi yeSiphaluka?

I-1.engining Yilo: Ilungiselelo lokunyanga i-interthayir Ibhodi ephambili ye-lamllayer engundoqo kunye nephepha eliphilisiweyo liya kwenziwa kumthengisi omnye; Indawo yegraphic yendiza yangaphandle ye-C / yeplanethi isondele, kwaye igridi ezimeleyo inokusetyenziswa.

2.Ukuba ipleyiti ngaphambi kokuba kufike i-pistrees: i-80 degrees iiyure ezingama-6 ukuya kweli-10, ayibandakanyi umphunga wamanzi kwiplate, qaphela uxinzelelo kwiplate; Iphepha lokubhaka ngaphambi kokuvula, zombini ungqimba kunye neemfuno zecala eliphindwe kabini!

3.Bufuthi, kufuneka ihlawulwe amalewa, ingqalelo kufuneka ihlawulwe kwi-warp kunye ne-Weft ye-Weft yeplate eqinileyo: I-Waff kunye ne-Wift kunye ne-Speinkige Shrizity Shriage Spired kunye nephepha eliqinileyo ngaphambi kokuba litshintshe iphepha eliqingqiweyo; Iplate engundoqo kufuneka inikele ingqalelo kwindlela ye-warp kunye ne-weft; Ulwalathiso ngokubanzi lwephepha lokunyangwa kweplate yindlela yaseMeridiyo; Indlela ende yeplate yobhedu iplate ye-medidaional; I-10 yeengqengqelo ze-4oz

4.Ubukhulu belilisa lokuphelisa uxinzelelo emva kokucinezela okubandayo, kunciphisa umda ovuthayo;

5.Bangela iplate ngaphambi kokubamba: i-150 degrees iiyure ezi-4;

6.it kungcono ukungayi kwibrashi yokugaya, ukucocwa kwamachiza kuyacetyiswa; Ingcali ekhethekileyo isetyenziselwa ukuthintela ipleyiti ukugoba kunye nokusonga

I-7.ATterter nganye ikhutshiwe kwi-tarble ye-carble okanye i-bit yentsimbi yendalo kwiqondo lobushushu okanye umoya odadayo webhedi yokuphola emva kokucoca;