Ngokubanzi: xa kuthelekiswa nenkqubo yokuvelisa ibhodi ye-multi-layer kunye ne-double-layer board, kukho iinkqubo ezi-2, ngokulandelanayo: umgca wangaphakathi kunye ne-lamination.

Ngokweenkcukacha: kwinkqubo yokuvelisa i-double-layer plate, emva kokuba ukusika kugqityiwe, ukugaya kuya kwenziwa, kwaye emva koko kubhedu, umgca; Kwinkqubo yokuvelisa ibhodi ye-multi-layer, emva kokuvulwa kwezinto ezigqityiweyo, ayiyi kuqhutyelwa ngokuthe ngqo, kodwa okokuqala kufuneka ihambe ngomgca wangaphakathi kunye ne-lamination, kwaye emva koko ingene kwi-workshop yokubhoboza, kwaye emva koko. kubhedu kunye nomgca.

Oko kukuthi, phakathi kwemingxuma yokuvula kunye nokubhoboza, iinkqubo ezimbini ze "line yangaphakathi" kunye ne "lamination" zongezwa. Oku ngasentla ngumahluko phakathi kwebhodi ye-multi-layer kunye ne-double-layer board production.

Okulandelayo, makhe sijonge ukuba zeziphi iinkqubo ezimbini zomgca wangaphakathi kunye ne-lamination

Umgca wangaphakathi

Inkqubo "yomgca" ekuveliseni amacwecwe aphindwe kabini, kubandakanywa ukunyanzeliswa kwefilimu, ukuvezwa, ukuphuhliswa (ukuba uyalibala, unokubuyela umva kwaye uyijonge).

"Isekethe yangaphakathi" apha ayilula kangako! Ukongeza kwifilimu ye-laminated yangaphakathi, ukubonakaliswa kwangaphakathi, ukuphuhliswa kwangaphakathi, kukwabandakanya unyango lwangaphambili lwangaphakathi, ukufakwa kwangaphakathi, ukususwa kwefilimu yangaphakathi kunye ne-AOI yangaphakathi.

Kwinkqubo yokuvelisa ipleyiti ephindwe kabini, ibhodi emva kokufakwa kobhedu kugqityiwe, ngaphandle komgca wokuvelisa, ngokuthe ngqo kwifilimu ecinezelayo, ngoko akukho mfuneko yokwenza unyango olongezelelweyo lwangaphambili. Kwaye ipleyiti yefoyile yobhedu apha, isanda kuvela kwindawo yokusebenzela yokusika, umphezulu webhodi uya kuba nokungcola,

Ngaphambi kwefilimu yangaphakathi ye-laminate, kuyimfuneko ukuqhubela phambili unyango kunye nokucoca, ukusetyenziswa kweekhemikhali zokusabela, kuqala ukususa ioli, amanzi, amanzi acocekileyo, i-micro-etching ezimbini (ukususa i-debris surface), kwaye emva koko amanzi, kwaye emva koko. ukuhlamba, umphezulu uya kuba oxidized, ngoko ke kufuneka pickling), emva koko amanzi, ngoko womile, uze ungene kwifilimu laminate yangaphakathi.

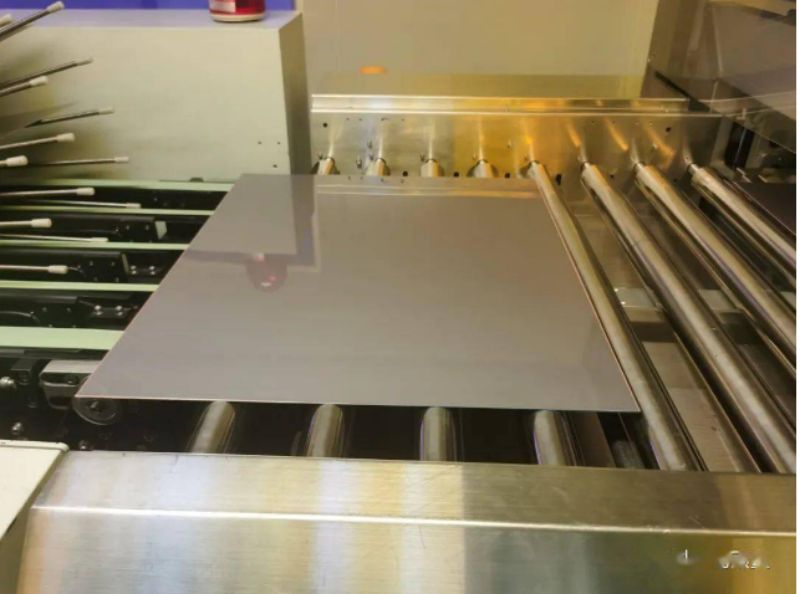

Ifilimu ye-laminate yangaphakathi ngaphambi kokuba unyango

Emva kokucinezela ibhodi, ngenxa yokuba ayizange iqhutywe, ibonakala icwecwe kakhulu.

Ukucinezela ifilimu, ukuvezwa, uphuhliso, imiba ethile yala makhonkco, iye yaziswa kwinqaku lemveliso yeplate ephindwe kabini, apha ayiyi kuphinda iphindwe.

Emva kokuba uphuhliso lugqityiwe, inxalenye yobhedu iya kubonakaliswa, kuba uluhlu lwangaphandle luyinkqubo yefilimu efanelekileyo, umgca wangaphakathi yinkqubo yefilimu engalunganga. Ngoko ke, emva kokuba uphuhliso lwangaphandle lugqityiwe, ubhedu oluvezwayo luyinxalenye efunekayo ukuba igcinwe, kwaye ubhedu oluvezwe emva kokuba uphuhliso lwangaphakathi luyingxenye ekufuneka igxininiswe, ngoko ke.

Inkqubo yokudibanisa yangaphakathi kunye nenkqubo yokukhangela yangaphandle nayo ihluke, ukubethelwa kwangaphakathi yinkqubo ye-alkaline, ngexesha lokudibanisa, ifilimu eyomileyo isekhona, inxalenye ngaphandle kwefilimu eyomileyo (ubhedu obuveziweyo) ifakwe kuqala, kwaye emva koko isikhunta siyasuswa.

I-etching yomaleko wangaphandle kuqala isuswe kwaye ifakwe, kwaye umgca ukhuselwe ngokuyinxenye yi-tin engamanzi.

Umgca wefilimu yangaphakathi, ekhohlo ijongene ne-etching, ilungelo lijongene nokuhoxiswa kwefilimu.

Emva kokumisa ibhodi yesiphaluka, ubhedu olugqithisiweyo lufakwe, kwaye inxalenye eseleyo yefilimu eyomileyo ayizange isuswe.

Ibhodi yesekethe emva kokuhluba.

Emva kokuba umgca wangaphakathi wefilimu ugqityiwe, umgca wangaphakathi womgca wenziwa ngokupheleleyo, ngeli xesha, kwaye emva koko i-AOI yokubona i-optical, ukufumanisa ukuba akukho ngxaki, unokuqhuba inkqubo yokuqhawula.

Lamination:

Yenza nje ibhodi, siyibiza ngokuba yibhodi yangaphakathi yangaphakathi, ukuba i-4 ibhodi yebhodi, kuya kuba nebhodi yebhodi yangaphakathi ye-1, ukuba i-6 ibhodi yebhodi, kuya kuba neebhodi ezi-2 zangaphakathi.

Injongo ephambili yale nkqubo kukwenza ipleyiti engundoqo yangaphakathi kunye nomgangatho wangaphandle udityaniswe kunye ukuze wenze yonke into. Inoxanduva lwezinto ezidityanisiweyo, ezibizwa ngokuba yiPP, isiTshayina esibizwa ngokuba yi-semi-curing sheet, eyona nto iphambili yiresin kunye nefiber yeglasi, iya kudlala kwakhona ibhodi engundoqo yangaphakathi kunye nenjongo yokufakwa kwefoyile yobhedu yangaphandle.

Ukuze kuqinisekiswe umgangatho webhodi enemigangatho emininzi, umthengisi we-PP we-Jialichuang useyi-Electronics yaseMzantsi Asia.

Ngokubanzi, inkqubo yokuthambisa yahlulwe yangamanyathelo amane ngokulandelelana: I-Browning, i-pre-stacking, i-platen, kunye nokucofa. Okulandelayo, makhe sijonge iinkcukacha zenkqubo nganye ngokwahlukeneyo.Ipleyiti engundoqo yangaphakathi emva kokuba ukususwa kwefilimu kugqitywe iba mdaka kuqala. Ibhodi yesekethe emdaka iya kongeza umaleko wefilimu emdaka ebusweni bebhodi yesekethe, eyona nto imdaka ngentsimbi, kwaye ubuso bayo bungalingani, ukwenzela ukuba kube lula ukubopha kunye nePP.

Umgaqo ufana xa kulungiswa isondo lebhayisikili, indawo ephukileyo kufuneka ifakwe kwifayile yokuphucula i-glue adhesion.

Inkqubo ye-Browning nayo yinkqubo yokusabela kweekhemikhali, eya kuhamba nge-pickling, i-alkali yokuhlamba, i-multi-channel yokuhlamba, ukomisa, ukupholisa kunye nezinye iinkqubo.

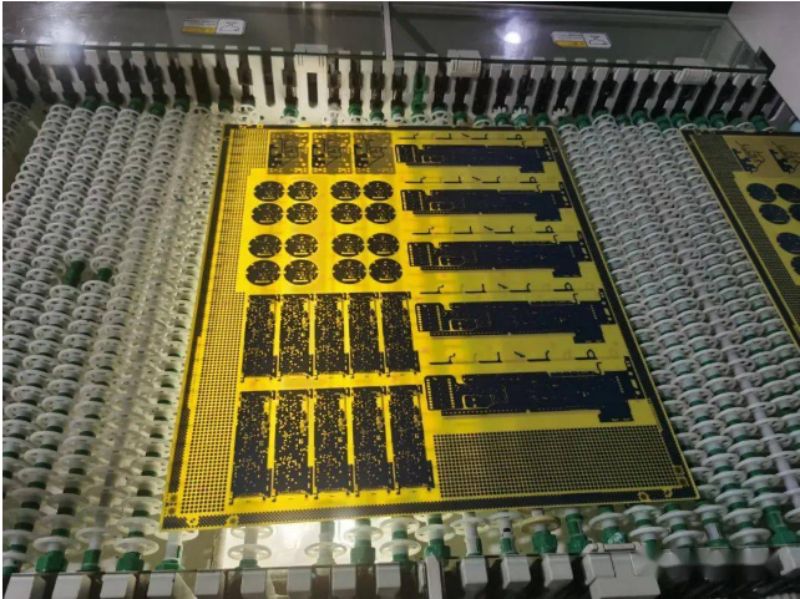

i-prelap

Inkqubo yokupakisha kwangaphambili, eyenziwa kwi-workshop engenathuli, iya kubeka i-core plate kunye ne-PP kunye. I-PP ibekwe kwicala ngalinye le-core plate. Ubude kunye nobubanzi bePP buya kuba yi-2mm enkulu kune-core plate ukukhusela imiphetho engenanto emva kokucinezela.

Isihlenga:

Injongo ephambili yeplate yomqolo kukongeza umaleko wefoyile yobhedu ngaphezulu koluhlu lwePP ukulungiselela umgca wangaphandle olandelayo. Ukongezelela, ipleyiti yensimbi kunye nephepha le-kraft liya kongezwa kwinqanaba elingaphandle.lamination

Amanyathelo okuqala ambalwa kukulungiselela i-lamination yokugqibela.

Ngaphambi kokuba i-laminating, ukwenzela ukukhusela i-warping, kuya kubakho isitya sokugubungela, malunga ne-12mm ubukhulu, intsimbi.

I-Laminating ibandakanya iinkqubo ezimbini zoxinzelelo olushushu kunye noxinzelelo olubandayo, ngokulandelanayo kwi-hot press kunye ne-cold press. Eli likhonkco elibaluleke kakhulu, ukuqwalasela izinto ezibandakanya i-vacuum, ubushushu, uxinzelelo, ixesha, ezi zinto zisebenzisana kunye, ukwenzela ukuvelisa iibhodi zeesekethe eziphezulu.

Ngokomzekelo, kwixesha elithile, ubungakanani bobushushu, ubungakanani bengcinezelo, nobude bexesha elifunekayo, kufanele kulungiswe ngokuchanekileyo.

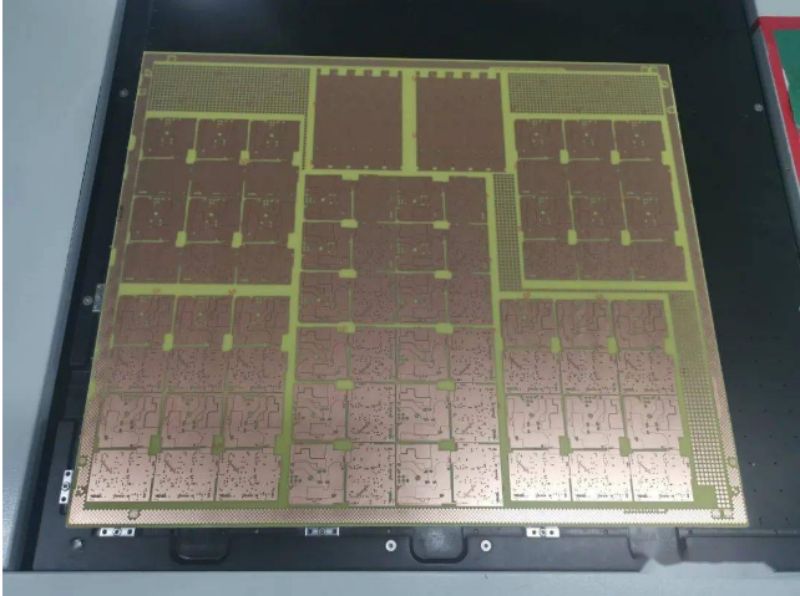

Emva kokuphela kwale nkqubo, i-PP kunye neplate yangaphakathi yangaphakathi kunye ne-copper foil yangaphandle iya kudibaniswa ngokusondeleyo.

Emva kokuphuma kumatshini wokushicilela, ukuchithwa ngokuzenzekelayo kuqhutywe, isitya sentsimbi sisuswe, kwaye sithunyelwa kwigumbi leplatoon kwakhona emva kokugaya. Njengoko kuboniswe kuMzobo we-11, umatshini ususa isitya sentsimbi.

Ibhodi yesekethe ye-laminated multi-layer iya kubuyiselwa kwiworkshop yayo yokuqala yokugrumba, kwaye yonke inkqubo iyafana nenkqubo yokuvelisa ibhodi ephindwe kabini.