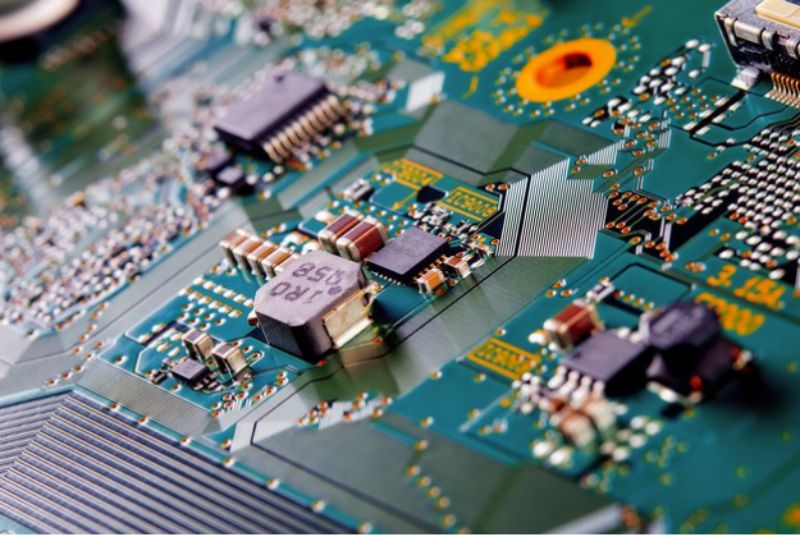

1. Qhagamshela iipads kwimingxunya. Ngokomgaqo, iingcingo phakathi kweepadi zokukhwela kunye nemingxuma kufuneka zithengiswe. Ukunqongophala kwemaski ye-solder kuya kukhokelela kwiziphene ze-welding ezifana ne-tin encinci kwi-solder joints, i-welding ebandayo, iisekethe ezimfutshane, ii-joints ezingafakwanga, kunye namatye engcwaba.

2. Uyilo lwemaski ye-solder phakathi kweepads kunye nemilinganiselo yepateni ye-mask ye-solder kufuneka ihambelane noyilo lwe-terminal ye-solder yokusabalalisa amacandelo athile: ukuba i-window-type solder resist isetyenziswa phakathi kweepads, ukuchasana kwe-solder kuya kubangela i-solder. phakathi kweepads ngexesha le-soldering. Kwimeko yesiphaluka esifutshane, iipads zenzelwe ukuba zibe ne-solder ezizimeleyo ezichasayo phakathi kwezikhonkwane, ngoko ke akuyi kubakho isiphaluka esifutshane phakathi kweepads ngexesha le-welding.

3. Ubungakanani bepateni yemaski ye-solder yamacandelo ayifanelekanga. Uyilo lwepateni yemaski ye-solder enkulu kakhulu "iyakhuselana" enye kwenye, kubangele ukuba kungabikho imaski ye-solder, kwaye isithuba phakathi kwezinto sincinci kakhulu.

4. Kukho imingxunya phantsi kwamacandelo ngaphandle kwemaski ye-solder, kwaye akukho maski ye-solder ngemingxuma phantsi kwezinto. I-solder kwimingxunya emva kwe-wave soldering inokuchaphazela ukuthembeka kwe-IC welding, kwaye inokubangela isiphaluka esifutshane samacandelo, njl.