I-1. I-pad yesikwere

Ihlala isetyenziswa xa izinto eziprintiweyo zikhulu kwaye zimbalwa, kwaye umgca oshicilelweyo ulula. Xa usenza i-PCB ngesandla, usebenzisa le pad kulula ukuyiphumeza

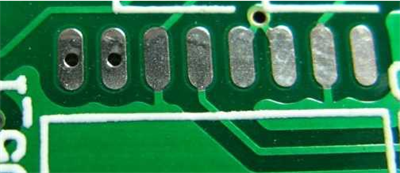

2.Untlapho

Isetyenziswe ngokubanzi kwiibhodi eziprintiweyo ezimbini kunye ne-Preyit, amalungu ahlelwa rhoqo. Ukuba ubukhulu beBhodi buvumela, iipads zinokuba nkulu kwaye aziyi kuwa ngexesha elithengiswayo.

3

I-pad-to-uqhagamshelo lwepali idityanisiwe. Isetyenziswa ngokuqhelekileyo kufakwa ngokungekho mthethweni.

I-4. I-Polygon Pad

Isetyenziselwa ukwahlula i-gasket ene-Diameter efanayo kunye needayamitha ezahlukileyo zenqanawa, ezilungele ukuqhubekeka nokuhlangana

I-5. I-Oval Padthe Pad inendawo eyaneleyo yokuphucula ubuchule bokuthintela amandla, ihlala isetyenziswa kwizixhobo ezibini zomgca

6.open pad pad

Ukuqinisekisa ukuba emva kokuthengiswa kwezabelo, imingxunya ye-PAD yokuTshintshela kwiNcwadi ayiyi kuvalwa ngumthengisi.

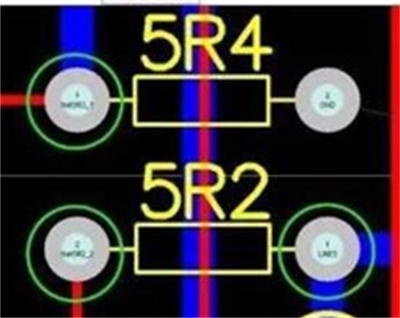

I-7. I-Prod

Iipads ezinomnqamlezo zikwabizwa ngokuba ziipads ze-thermal, iipads zomoya ezishushu, njl. Njl.

● Xa iipads zakho zisemhlabeni. Intyatyambo enomnqamlezo enomnqamlezo inokunciphisa indawo yoqhagamshelo lwe-wire, icothe isantya sokulimaza ubushushu, kwaye siququzelele ukuba sempilweni.

● Xa i-PCB yakho ifuna ukubekwa ngomatshini kwaye ifuna umatshini wokurhweba ngokungxama, ipali enomnqamlezo inokuthintela i-PCB isuka kwi-PCB isuka (ngenxa yokuba ubushushu obungaphezulu bufuneka ukuze bunyibilike i-Phuter Pay)

I-8. Teardrop pad

Ihlala isetyenziselwa xa umkhondo oqhotyoshelwe kwi-liner ucekeceke, ukuthintela ukuthambisa i-liner kunye nokunqunyanyiswa komkhondo kwi-liner. Le mlilo ihlala isetyenziswa kwisekethe ephezulu