I-PCBS kwiimveliso ezincinci ziyinxalenye yesixhobo se-elektroniki sanamhlanje. Ubungqingqwa bobhedu yinto ebaluleke kakhulu kwinkqubo yokwenza imveliso yePCB. Ubungakanani obuchanekileyo bobhedu unokuqinisekisa umgangatho kunye nokusebenza kweBhodi yeSiphaluka, kwaye kuchaphazela ukuthembeka kunye nokuzinza kweemveliso ze-elektroniki.

Ngokubanzi, ubukhulu bethu obuqhelekileyo bobhedu yi-17.5um (0.5Oz), 35um (1oz), i-70m (2oz)

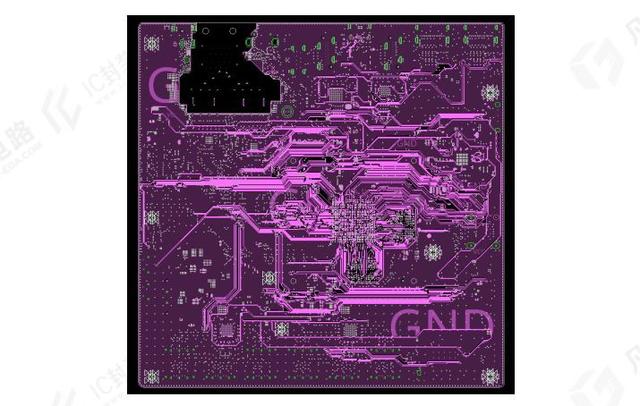

Ubungqingqwa bobhedu bumisela ukwenziwa kombane kwiBhodi yeSiphaluka. Ubhedu yinto ebalaseleyo, kwaye ubukhulu bayo buchaphazela ngokuthe ngqo isiphumo sebhodi yesekethe. Ukuba ungqameko lobhedu luthambile kakhulu, iipropathi ezisebenzayo zinokuncipha, zikhokelela kunxibelelwano lokuhambisa umqondiso okanye ukungazinzi kwangoku. Ukuba ungqameko lobhedu lunzima kakhulu, nangona ukuqhubela phambili kuya kuba kulunge kakhulu, kuya kwandisa indleko kunye nobunzima beBhodi yeSiphaluka. Ukuba umaleko wobhedu yinto enkulu kakhulu, iya kukhokelela ngokulula kwiglue enkulu ihamba iqukuqela, kwaye ukuba i-diecturi yomaleko icekeceke, ubunzima benkqubo yesekethe buya kukhula. Ke ngoko, i-2oz yobhedu ayikacetyiswa. Ukuqulunqwa kwemveliso ye-PCB, ubukhulu bobuchwephesha bobhedu kufuneka kukhethwe ngokusekwe kwiimfuno zoyilo kunye nokusetyenziswa kwebhodi yesekethe ukuze kufezekiswe ezona ziphumo zibalaseleyo.

Okwesibini, ubukhulu becala bunefuthe elibalulekileyo kubushushu bokuchitha ubushushu beBhodi yeSiphaluka. Njengoko izixhobo ze-elektroniki zangoku ziya kuba zinamandla ngakumbi, ngakumbi kwaye ubushushu obungaphezulu buveliswa ngexesha lokusebenza kwabo. Umsebenzi wokuSebenzisa ubushushu onobushushu unokuqinisekisa ukuba amaqondo obushushu eenxalenye ze-elektroniki alawulwa ngaphakathi kodidi olukhuselekileyo ngexesha lokusebenza. Ungqameko lobhedu lusebenza njengomaleko olwenziwe nge-thermal yebhodi yebhodi, kwaye ubukhulu bayo bubonisa isiphumo se-Heat. Ukuba ungqameko lobhedu luthambile kakhulu, ubushushu bungayi kuqhutywa kwaye buye bachitha ngokufanelekileyo, banyuse umngcipheko wezinto.

Ke ngoko, ubukhulu bobhedu lwe-PCB alunakuba mncinci kakhulu. Ngexesha lenkqubo yoyilo lwe-PCB, sinokubeka ubhedu kwindawo engenanto ukunceda ukulimaza kobushushu kwiBhodi yePCB. Ukuvelisa i-PCB, ukukhetha ubukhulu bobhedu olufanelekileyo kunokuqinisekisa ukuba iBhodi yeSeva ineeNdawo zokuSebenza. intsebenzo yokuqinisekisa ukusebenza ngokukhuselekileyo kwezixhobo ze-elektroniki.

Ukongeza, ubukhulu becala bunefuthe elibalulekileyo ekuthembekeni nasezizinzo kwiBhodi yeSiphaluka. Umaleko wobhedu awusebenzi nje njengombane wombane nowamdla ngokuthe ngqo, kodwa usebenza njengenkxaso kunye nonxibelelwano kwiBhodi yeSiphaluka. Ubungqingqwa bobhedu olufanelekileyo lunokubonelela ngamandla aneleyo okuthintela iBhodi yeSekethe ukusuka ekugobeni, ukophula okanye ukuvula ngexesha lokusetyenziswa. Kwangelo xesha, ubukhulu bobhedu olufanelekileyo olufanelekileyo lunokuqinisekisa umgangatho we-welding weBhodi yeBhodi kunye nezinye izinto kwaye unciphise umngcipheko wesiphene se-welding kunye nokusilela. Ke ngoko, kwimveliso ye-PCB, ukukhetha ubungqingqwa bobhedu obufanelekileyo kunokuphucula ukuthembeka kunye nokuzinza kweBhodi yeSiphaluka kwaye kwandise ubomi benkonzo kwiimveliso ze-elektroniki.

Ukuzama ukuphakamisa ubukhulu bobhedu kwimveliso ye-PCB ayinakutyeshelwa. Ubungakanani obuchanekileyo bobhedu unokuqinisekisa ukuqhekeka kombane, ukusebenza kobushushu bokusebenza, ukuthembeka kunye nozinzo kwiBhodi yeSiphaluka.

Kwinkqubo yokwenyani, kuyimfuneko ukukhetha ubukhulu bobuchwephesha bobhedu olusekwe kwizinto ezinjengeemfuno zeBhodi yeSiphaluka, iimfuno zomsebenzi, kunye nolawulo lweendleko ukuqinisekisa ukuba umgangatho kunye nokusebenza kweemveliso ze-elektroniki. Kuphela ngale ndlela kuphela apho kunokwenzeka ukuba i-PCB ekumgangatho ophezulu iveliswa ukuze ifezekise ukusebenza okuphezulu kunye nokuthenjwa okuphezulu kwezixhobo ze-elektroniki zangoku.