Kwindlela yokuyila ye-PCB, ubume bezinto zibaluleke kakhulu, ezigqiba inqanaba elincinci leBhodi kunye nobude be-wire eprintiweyo, kwaye inefuthe elithile kulwaliso lomatshini uphela.

Ibhodi yesekethe elungileyo, ukongeza ekufezekisweni komgaqo womsebenzi, kodwa nokuthatha ingqalelo i-EMI, i-EMC, i-ESD (i-ESD (i-Electrostatic), ukungqinelana nemilinganiselo yoomatshini, i-chip enkulu ye-CHIP yobushushu.

Iimfuno zeNtetho yePCB yePCB

1, Funda uxwebhu lwenkcazo yoyilo, dibana nolwakhiwo olukhethekileyo, imodyuli ekhethekileyo kunye nezinye iimfuno zokubekwa.

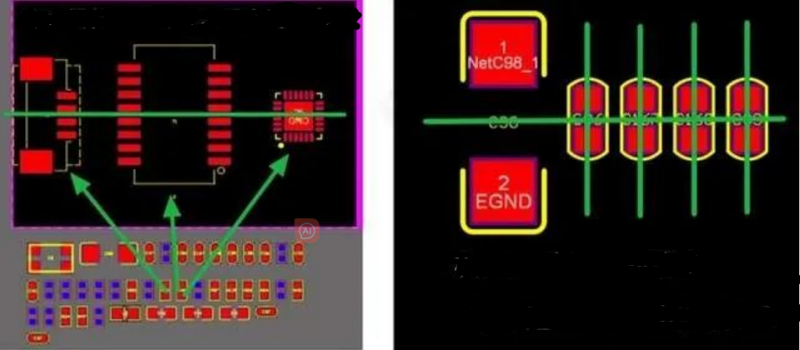

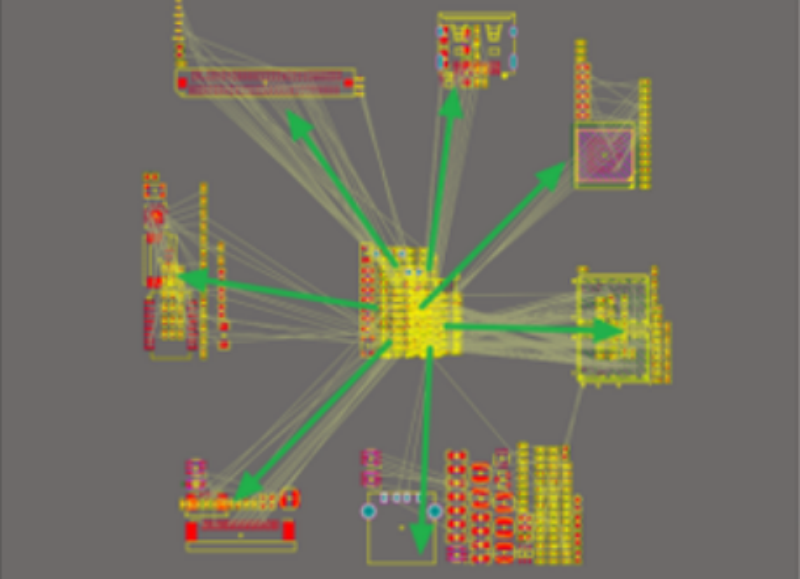

2, Beka inqaku le-Grid Grid ukuya kwi-25 Mila, linokuhambelana nenqaku legridi, isithuba esilinganayo; Imowudi yolungelelwaniso inkulu ngaphambi kwenciniba (izixhobo ezinkulu kunye nezixhobo ezinkulu zihambelana kuqala), kwaye indlela yolungelelwaniso liziko, njengoko kubonisiwe kwinani elilandelayo

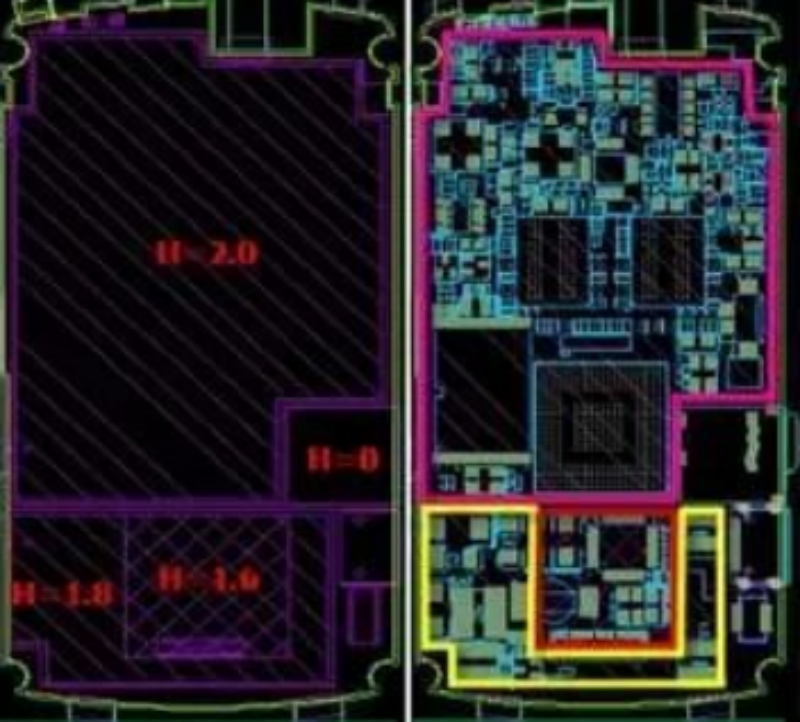

3, dibanisa umda onqabileyo wendawo, ulwakhiwo kunye nesakhiwo esikhethekileyo sefowuni, iimfuno zendawo enqamlezileyo.

① Umzobo 1 (ngasekhohlo) apha ngezantsi: Iimfuneko eziphakamileyo zokulinganisa, ziphawulwe ngokucacileyo kwi-counter yomatshini okanye iManyano, ilungele ukutshitshiswa kwe-ross-fack-fack-facket-ftware;

.

Ubeko lwesakhiwo kunye nezixhobo ezizodwa zinokubekwa ngokuchanekileyo ngokulungelelanisa okanye ngokulungelelanisa kwesakhelo sangaphandle okanye umnombo weziko.

4, Ubeko lufanele lube nendawo yokuqala, ungayifumani iBhodi ukuqala uyilo olusekwe kwimodyuli yemodyuli, emva koko ivavanye imeko yemodyuli yemodyuli yemodyuli kwi-PCB kunye nobungakanani bendawo yokuhlala. Zoba ububanzi bomgangatho wobunzima obuncedisayo

5, indlela kufuneka ithathele ingqalelo ijelo elishiya intambo yamandla, akufuneki libe nzima kakhulu, ngokucwangciswa ukuba iphume phi, cond umthi wamandla

Iinxalenye ezi-6, ezifana namandla e-elektrolytic, i-crystal ye-crystal ye-crystal) ikwakude nokuhambisana kwamandla kunye nezinye izixhobo eziphezulu ze-shormal, ukuya kuthi ga ngoku kunokwenzeka

7, Ukuhlangabezana nolwahlulo lwemodyuli ebuthathaka, yonke ibhalansi yeBhodi, iBhodi iphela i-Wing Inshouve

I-voltage ephezulu kunye nemiqondiso ephakamileyo yahlulekile ngokupheleleyo kwimiqondiso ebuthathaka yemijelo emincinci kunye ne-voltages ephantsi. Amacandelo aphezulu evolvage axhonywe kuyo yonke indawo ngaphandle kobhedu olongezelelekileyo. Umgama we-cerepage phakathi kwamalungu eevolthi eziphakamileyo itshekishwe ngokungqinelana netafile esemgangathweni

Umqondiso we-analog wahlukaniswa nomqondiso wedijithali kunye nobubanzi beminyaka engama-20mlil, kwaye i-analog kunye ne-rf ilungiselelwe kwi-Ansil Ark

Isayina ePhakamileyo ePhakamileyo yahlukaniswa kwisayini ye-Right ephantsi, umgama wokwahlula-hlula ubuneminyaka emi-3mm, kwaye umnqamlezo onqamlezileyo awunakuqinisekiswa

Ubume bezixhobo eziphambili zomqondiso ezifana ne-cryscillator kunye nomqhubi we-clock kufuneka zikude kakhulu kumemoshelo wesiphaluka, hayi kumphetho weBhodi, kwaye ubuncinci i-10mm kude nomphetho weBhodi. I-crystal kunye ne-crystal oscillator kufuneka ibekwe kufutshane ne-chip, ibekwe kwi-chip efanayo, musa ukukhonkotha imingxunya, kunye nendawo yomhlaba

Isisekethe esifanayo sesekethe, sinomgangatho oqhelekileyo "wokulinganisa"

Emva koyilo lwe-PCB, kufuneka senze uhlalutyo kunye nokuhlolwa ukwenza imveliso igudile ngakumbi.