Iimeko eziyimfunekoI-PCB engaxhomekekiIibhodi zesekethe

1.Umlobi omele ukuba unempindezelo olungileyo

Itekisi eyoyikisayo ibhekisa ekusebenzeni kwe-alloy yokuba izinto zentsimbi zibekwe kwaye umthengisi unokwenza indibaniselwano elungileyo kubushushu obufanelekileyo. Ayizizo zonke iintsimbi zinokuqhekeka okulungileyo. Ezinye izinyithi, ezinjengeChromium, iMolybdenum, ityhunxa, njl njl. Ezinye zezinyithi, ezinje ngobhedu, ubhedu, njl njl. Ngexesha le-welding, ubushushu obuphezulu bubangela ifilimu ye-ox ox ox agoal of kumphezulu wensimbi, echaphazela i-wild yezinto ezibonakalayo. Ukwenzela ukuphucula ukuthengisa, ukubekwa kwe-tin engaphezulu, ukubethwa kwesilivere kunye namanye amanyathelo kunokusetyenziselwa ukuthintela i-oxidation tuction.

2.Umphezulu wendalo kufuneka ugcinwe ucocekile

Ukuze kufezekiswe indibaniselwano elungileyo yomthengisi kunye ne-welloment, umphezulu we-welding kufuneka ugcinwe ucocekile. Kwanakwizinto ze-welds ezinomzimba ofanelekileyo, iifilimu ze-oxide kunye namabala e-oyile kunye namabala e-oyile ayonzakalisayo kuvalwa kumphezulu wendalo ngenxa yokugcina okanye ukungcola. Ifilimu emdaka kufuneka isuswe ngaphambi kokuba i-welding, kungenjalo umgangatho we-welding akanakuqinisekiswa. Ukudakumba kweyona fideeside kwimiphezulu yensimbi inokususwa yi-flux. Iindawo zensimbi nge-oxidation enkulu kufuneka isuswe ngeendlela zoomatshini okanye zeekhemikhali, njengokukrokra okanye ukhangela.

3.Umntu ofanelekileyo

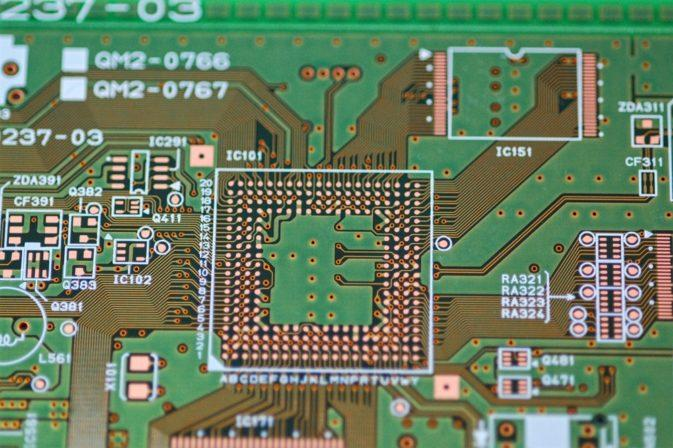

Umsebenzi we-flux kukukhupha ifilimu yesidilveyithi kumphezulu wendalo. Inkqubo eyahlukeneyo ye-welding ifuna i-fluxes eyahlukileyo, efana neNickel-Chromium Allomium, intsimbi engenanto, ialuminiyam kunye nezinye izixhobo. Kunzima ukuya kwithembeko ngaphandle kwe-guble ekhethekileyo. Xa i-welding ichanekayo kwimveliso ye-elektroniki efana neebhodi zesekethe eziprintiweyo, ukuze zenze i-uplling ethembekileyo kwaye izinzile, i-rosin esekwe eRosin ihlala isetyenziswa. Ngokubanzi, utywala busetyenziselwa ukunyibilikisa iRosin emanzini eRosin.

I-4. I-weldenment kufuneka ifuduselwe kubushushu obufanelekileyo

Ngexesha le-welding, ukusebenza kwamandla e-thermal kukunyibilikisa umrhwebi kwaye ubushushu into ye-welding, ukuze i-tin kunye ne-tin kunye ne-atom kunye ne-atom kunye ne-atom kunye ne-atom kunye ne-atom ifumane amandla aneleyo kwi-seltice yokwakha isabelo sensimbi. Ukuba iqondo lobushushu le-welding liphantsi kakhulu, liya kuba yingozi ekungeneni kweatom yomthengi, esenza ukuba kungenzeki ukwenza i-alloy, kwaye kulula ukwenza iThutho lobuxoki. Ukuba ubushushu be-welding bukhulu kakhulu, umrhwebi uya kuba kwisimo se-En-theectic, ekhawulezisa ukubola kunye nenqanaba lokungcungcutheka kwe-flux, ebangela ukuba iipads kwibhodi yesiphaluka eprintiweyo ihlulekile. Yintoni ekufuneka igxininiswe kukuba ayisiyiyo kuphela i-tserder kuphela kufuneka ifudunyezwe ukuba inyibilike, kodwa i-wellomenti ifudunyele kubushushu obunokunyibilika irhwebi.

I-5. Ixesha elifanelekileyo le-welding

Ixesha le-welding libhekisa kwixesha elifunekayo lotshintsho lomzimba kunye nekhemikhali ngexesha lenkqubo ye-welding. Iquka ixesha lesinyithi ukuba libe selokuba lifikelele kubushushu be-welding, ixesha lokunyibilika komthengisi, ixesha lokuba i-flux isebenze kunye nexesha le-alloy yesabelo. Emva kokuba iqondo lobushushu le-welding limisiwe, ixesha elifanelekileyo le-welding kufuneka limiselwe ngokusekwe kubume, ubume, kunye neempawu zelungu lezilwanyana. Ukuba ixesha le-welding lide kakhulu, izinto okanye iinxalenye ze-welding ziya konakala; Ukuba ixesha le-welding lifutshane kakhulu, iimfuno ze-welding aziyi kufezekiswa. Ngokubanzi, elona xesha liphezulu kwiThuthi nganye yeThuthi ukuba i-weldard ayingaphezulu kwemizuzwana emi-5.