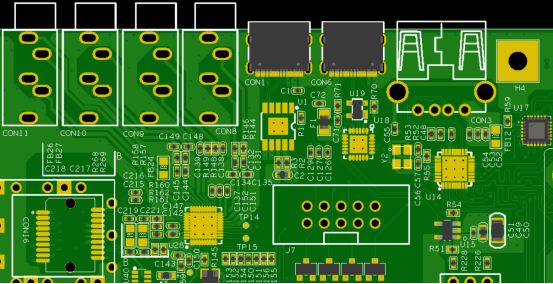

Ngokuphathelele ubume be-PCB kunye nengxaki ye-wiring, namhlanje asizukuthetha ngohlalutyo lweNgxowa-themba (i-SI), i-Electromagnetic yokuLungisa (EMC), Uhlalutyo lokugcina i-PI). Ukuthetha nje ngohlalutyo lwenzala (i-DFM), uyilo olungenangqondo lwenzala luya kukhokelela ekusilelasweni koyilo lwemveliso.

Impumelelo ye-DFM kwimo ye-PCB iqala ngokuseta imithetho yoyilo ukuze incedise kwizithintelo ze-DFM. Imigaqo ye-DFM eboniswe ngezantsi ibonakalisa ukuba uninzi lwezakhono zoyilo olunokuthi lufumane khona abavelisi. Qinisekisa ukuba imida ebekiweyo kwiMithetho yoYilo yePCB ayiziphulaphuli ukuze izithintelo zendlela zoyilo zinokuqinisekiswa.

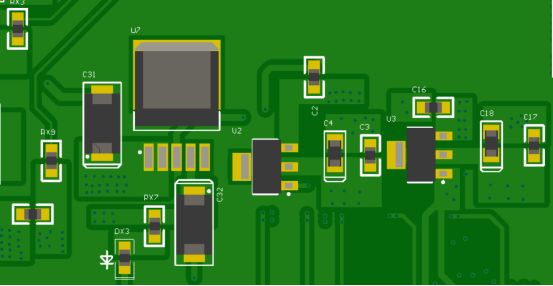

Ingxaki ye-DFM ye-PCB ixhomekeke kwi-PCB elungileyo yePCB, kwaye imithetho yemithetho inokubekwa ngaphambili, inani lemingxunya yokusebenza yenziwa kuqala ukudibanisa imigca emifutshane ngokukhawuleza, kwaye emva koko i-lebyrity wirity wirint iqhutywa. I-windows ye-Global Roultion yenziwa kwiingcingo ze-wiires ukuba ibekwe kuqala, kwaye i-wiring iphinde ifake i-wiring ifakiwe ukuphucula iziphumo ngokubanzi kunye nenzala ye-DFM.

I-1.SSMT izixhobo

Isithuba sokubekwa kwesixhobo sihlangabezana neemfuno zendibano, kwaye ngokubanzi inkulu kune-20mil yeZixhobo eziPhintelweyo ezingaphezulu komhlaba, i-80MIL yezixhobo zeCA, kunye ne-200MI yezixhobo ze-BGA. Ukwenzela ukuphucula umgangatho kunye nesivuno senkqubo yemveliso, isithuba sesixhobo sinokuhlangabezana neemfuno zendibano.

Ngokubanzi, umgama phakathi kweepads ze-SMD zezikhonkwane zesixhobo kufuneka zinkulu kune-6mIl, kunye nobungakanani be-tsobrer ye-tsorjer yeThufa yeThuthi yeThufa yomthengi yi-4EMIL. Ukuba umgama phakathi kweepads ze-SMD zingaphantsi kwe-6mil kunye nomgama phakathi kwefestile yeThuqu ingaphantsi kwe-4mIl, ibhulorho enkulu ayinakugcinwa, eyakhokelela kwisekethe emfutshane.

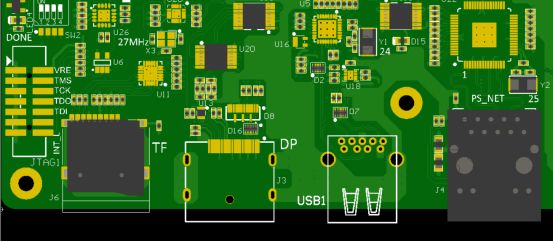

I-2.dip isixhobo

Isithuba sePIN, isikhokelo kunye nenqanaba lezixhobo kwinkqubo yokuthengiswa kwe-wave kufuneka kuthathelwe ingqalelo. Isithuba sePIN esaneleyo sesixhobo siya kukhokelela kwi-tin engekho mthethweni, esiya kukhokelela kwisekethe esifutshane.

Abayili abaninzi banciphisa ukusetyenziswa kwezixhobo ze-intanethi (thts) okanye abeke kwicala elinye leBhodi. Nangona kunjalo, izixhobo ze-intanethi zihlala zingenakuthintelwa. Kwimeko yokudityaniswa, ukuba isixhobo se-in-intanethi sibekwe kwi-famite ephezulu kunye nesixhobo se-patch sibekwe kwi-fayider engezantsi, kwezinye iimeko, kuya kuchaphazela ukuthengiswa kwecala elinye. Kule meko, iinkqubo ze-welding kakhulu ze-welding, ezinjengokukhetha i-welding, ziyasetyenziswa.

3. umgama phakathi kwamacandelo kunye nomphetho weplate

Ukuba ngumatshini we-welding, umgama phakathi kwamacandelo e-elektroniki kunye nomphetho weBhodi ngokubanzi

Nangona kunjalo, xa umphetho weplate wenziwe, unokudibana nesikhokelo sololiwe womatshini kwaye wonakalise izinto. I-pad yefowuni kumda weplate iya kususwa kwinkqubo yokuphucula. Ukuba i-pad incinci, umgangatho we-welding uya kuchaphazeleka.

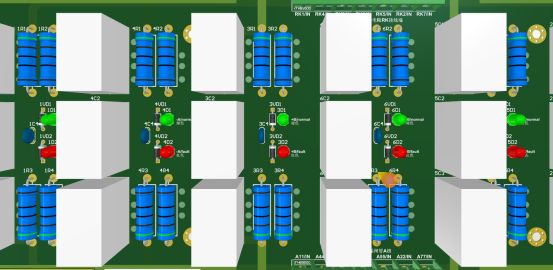

4.Izixhobo eziphezulu / eziphantsi

Zininzi iintlobo zezinto ze-elektroniki, iimilo ezahlukileyo, kunye nemigca eyahlukeneyo ye-Coundi, ke kukho umahluko kwiNdibano yeeBhodi eziprintiweyo. Ubume obulungileyo abunakwenze kuphela umsebenzi ozinzileyo womatshini, ubungqina bothusayo, bunciphisa umonakalo, kodwa banokufumana ifuthe elicocekileyo nelisebenza ngaphakathi komatshini.

Izixhobo ezincinci kufuneka zigcinwe kumgama othile ojikeleze izixhobo eziphakamileyo. Umgama wesixhobo ukuya kumlinganiso wokuphela kwesixhobo sincinci, kukho i-suve engalinganiyo, enokubangela umngcipheko we-welding okanye ukulungiswa emva kwe-welding.

5.Device kwi-spacting yesixhobo

Ukuqhubekisa ngokubanzi kwe-SMT, kunyanzelekile ukuba kuthathelwe ingqalelo iimpazamo ezithile ekuphakameni komatshini, kwaye uthathele ingqalelo lula ukugcinwa kunye nokuhlolwa okubonakalayo. Ezi zinto zibini zikufuphi akufuneki zibe kufutshane kakhulu kwaye umgama othile okhuselekileyo kufuneka ushiywe.

Isithuba esiphakathi kwamacandelo aphantsi, i-sot, i-sooc kunye necandelo le-flake li-1.25mm. Isithuba esiphakathi kwamacandelo aphantsi, i-sot, i-sooc kunye necandelo le-flake li-1.25mm. I-2,5mm ye-PlCC kunye necandelo le-flake, isoto kunye ne-qfp. I-4mm phakathi kwe-plcs. Xa uyila iziseko ze-PPCI, ukhathalelo kufuneka luthathelwe ukuvumela ubungakanani besokisi ye-plcc (iphini yePPCC ingaphakathi kwesokisi).

6.Liner / umgca womgangatho

Abaqulunqi, kwinkqubo yoyilo, asinakuqwalasela nje kuphela ukuchaneka kunye nokugqibelela kweemfuno zoyilo, kukho isithintelo esikhulu yinkqubo yemveliso. Akunakwenzeka ukuba umzi-mveliso webhodi ukwenza umgca omtsha wemveliso yokuzalwa kwemveliso elungileyo.

Phantsi kweemeko eziqhelekileyo, ububanzi bomgca owenziweyo bulawulwa ukuya kwi-4 / 4mil, kwaye umngxunya ukhetha ukuba yi-8ml (0.2mm). Ngokusisiseko, ngaphezulu kwe-80% yemveliso yePCB inokuvelisa, kwaye iindleko zemveliso zezona ziphantsi. Ubuncinci bomgangatho wobubanzi bomgangatho kunye nomgama womgca ungalawulwa kwi-3 / 3mil, kunye ne-6mil (0.15mm) inokukhethwa ngomngxunya. Ngokusisiseko, ngaphezu kwe-70% abavelisi be-PCB banokuyivelisa, kodwa ixabiso liphezulu kakhulu kunemeko yokuqala, hayi ngaphezulu kakhulu.

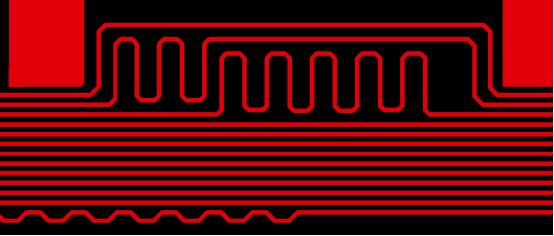

7.Ngaba i-angle ye-able / ngasekunene

I-angle ye-angle ye-BHARP ayivumelekanga ngokubanzi kwi-wiring, i-angle ye-angle yasekunene inyanzelekile ukuba ithintele imeko kwi-PCB indala, kwaye iphantse yaba ngomnye wemigangatho yokulinganisa umgangatho we-wiring. Ngenxa yokuba ingqibelelo yomqondiso iyachaphazeleka, i-wiring ye-angle elungileyo iya kuvelisa amandla ongezelelweyo kunye nengxaki.

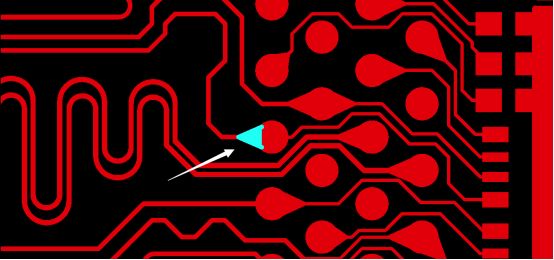

Kwinkqubo yeplate ye-PCB, iingcingo ze-PCB zingena kwi-engile ye-acle, eziya kubangela ingxaki ebizwa ngokuba yi-Acid Combe. Kwikhonkco lokunxibelelana ngesekethe ye-PCB, ukulungela ukuvela okugqithisileyo kwesekethe ye-PCB kuya kubangelwa kwi "Acid Cole", kukhokelela kwingxaki ye-PCB yesekethe ye-PCB. Ke ngoko, iinjineli zePCB kufuneka ziphephe ii-angles ezibukhali okanye ezingaqhelekanga kwi-wiring, kwaye zigcine i-45 degree angle kwikona ye-wiring.

8.Copper Strip / Island

Ukuba ngumququzeleli wesiqithi esikhulu ngokwaneleyo, iya kuba yi-eriyali, enokubangela ingxolo kunye nolunye uphazamingene ngaphakathi kwiBhodi (kuba ubhedu lwalo alubalulekanga - luya kuba ngumqokeleli womqondiso).

Imigca ye-Copper kunye neziqithi zininzi ii-flat zobhedu olunenkululeko kwaye lunokubangela ezinye iingxaki ezinkulu kwi-Acid Thoule. Amabala amancinci obhedu sele eyaziwa ukuba ahlukane nephaneli ye-PCB kwaye ahambe kwezinye iindawo ezigciniweyo kwiphaneli, ebangela isiphaluka esifutshane.

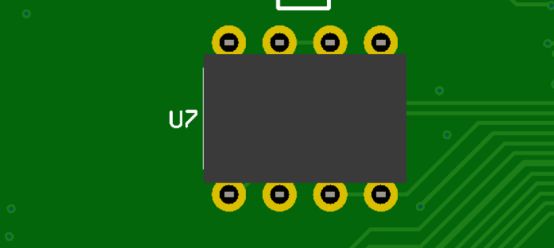

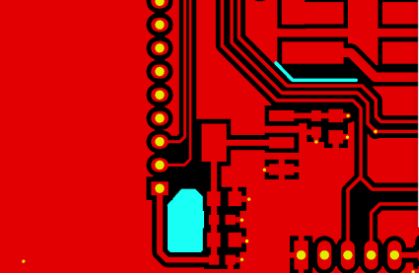

9.Iza ngomsindo wemingxunya yokuqhuba

I-ring yomnyazi ibhekisa kwi-ring yobhedu malunga nomngxunya we-dill. Ngenxa yokuqina kwenkqubo yokwenziwa, emva kokubamba, ukubetha, kunye nobhedu, umsesane oshiyekileyo ujikeleze umngxunya wepali ngokugqibeleleyo, onokubangela umkhangeli wengca.

Elinye icala lomthi womngxunya kufuneka libe likhulu kune-3.5mil, kunye ne-plug-kwintsimbi yomngxunya kufuneka ibe nkulu kune-6mil. I-ring yomsindo incinci kakhulu. Kwinkqubo yemveliso kunye nemveliso, umngxunya wokuqhuba uneengxaki kunye nolungelelwaniso lomgca unezidima. Ukuphambuka konyamezelo kuya kukhokelela kwikhonkco lomngxunya ukwaphula isekethe evulekileyo.

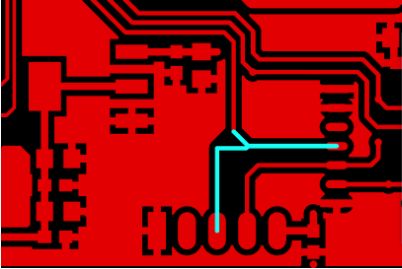

10.Igadi yetrayi ye-wiring

Ukongeza iinyembezi kwi-PCB Wiring kunokwenza uqhagamshelo lwesekethe kwiBhodi yePCB ngakumbi, ukuthembeka okuphezulu, ukuze inkqubo ibe zizinzile ngakumbi, ngoko ke imfuneko yongeza iinyembezi kwibhodi yesekethe.

Ukongezwa kwamathontsi eenyembezi kunokuphepha ukunqunyanyiswa kwendawo yoqhakamshelwano phakathi kwecingo kunye nepali okanye icingo kunye nomngxunya we-Pinot xa iBhodi yePilot xa iBhodi yeSekethe ichaphazeleka ngamandla amakhulu angaphandle. Xa usongeza i-Deling ye-welding, inokukhusela i-pad, kuphephe i-welding ezininzi ukwenza i-pad iwele, kwaye ukuphepha i-etching engalinganiyo kunye ne-racking e-etching kunye ne-racking ebangelwe yi-HoE.