Intshayelelo yeVia-in-pad:

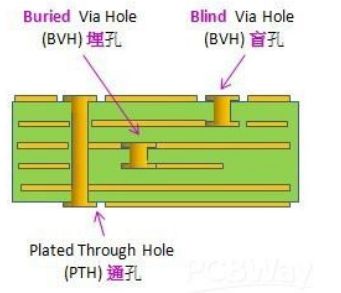

Kuyaziwa ukuba i-VIAS (nge) inokwahlulwa ibe ifakwe ngomngxunya, umngxunya ongaboniyo Vias kunye nomngxunya weViasis Vias, onemisebenzi eyahlukeneyo.

Ngokuphuhliswa kweemveliso ze-elektroniki, i-VIAS idlala indima ebalulekileyo kunxibelelwano lweqela lesekethe eliprintwayo. I-pid-in-pad isetyenziswe ngokubanzi kwi-PCB encinci kunye ne-BGA Ngophuhliso olungenakufikelelwa koxinzelelo oluphezulu, i-BGA (i-BGA (iBrid Grid) kunye ne-SMD Chiprizulu, ukusetyenziswa kwetekhnoloji ye-phec-in-pid iya kusilela ngakumbi nangakumbi.

UVias kwiipads uneengenelo ezininzi ngaphezu kwemfama kwaye wangcwatyelwa nguVias:

. Ilungele i-pitch ye-pitch ehle.

. Kulungele ukuyila i-PCB yePCB iPhezulu kwaye igcine indawo yokudinwa.

. Ulawulo lwe-thermal olungcono.

. I-anti-inctuary ephantsi kunye noyilo oluphezulu oluphezulu.

. Ibonelela ngomphezulu weglasi yamacandelo.

. Ukunciphisa indawo yePCB kwaye phucula ngakumbi i-wiring.

Ngenxa yezi zibonelelo, i-pad-in-pad isetyenziswe ngokubanzi kwii-PCB ezincinci, ngakumbi kwii-PCB zokudlulisela apho kudluliselwe ubushushu kwaye isantya esiphezulu siyadingeka nge-BGA ye-BGA. Nangona imfama kwaye ingcwatywe i-vias inceda ukunyusa ukungcungcutheka kwaye igcine indawo kwii-PCBs, i-VIASs kwiipads zisesona sikhetho sibalaseleyo solawulo lobushushu kunye nesantya esiphezulu soyilo.

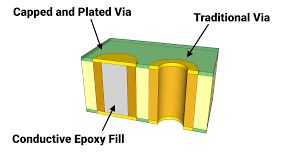

Ngethemba lokuthembeka ngokugcwalisa / ukubeka inkqubo ye-Implet, ngeTekhnoloji ye-pad inokusetyenziselwa ukuvelisa i-PCBS yePCB ePhakamileyo ngaphandle kokusebenzisa izindlu zemichiza kunye nokuphepha iimpazamo zokungafakwanga. Ukongeza, oku kunokubonelela ngeengcingo ezongezelelweyo zokudibanisa iingcingo ze-BGA.

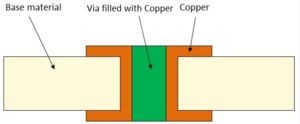

Kukho izixhobo ezahlukeneyo zokugcwalisa umngxunya kwiplate, i-Compasis yeSilivere kunye ne-Copper Coupen zihlala zisetyenziselwa izixhobo zokusebenza, kwaye i-resin isetyenziselwa izixhobo ezingasebenziyo