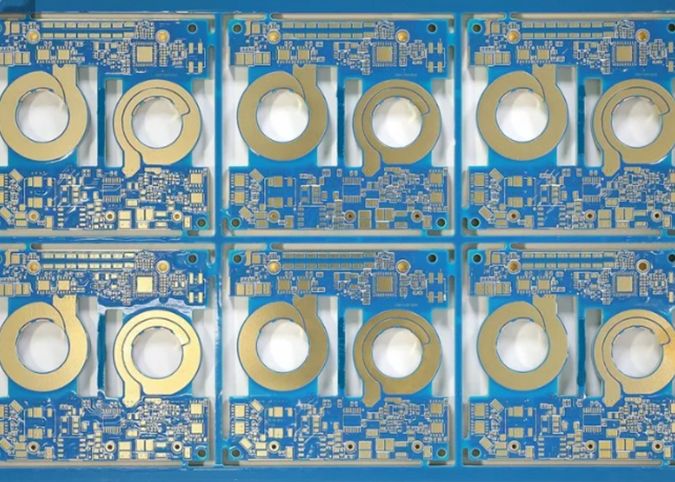

Izinto zesekethe zixhomekeke kubaqhubi abakumgangatho ophezulu kunye nezixhobo ze-dielectric ukudibanisa amacandelo anamhlanje anzima omnye komnye ukuze asebenze ngokufanelekileyo. Noko ke, njengoko abaqhubi, ezi baqhubi PCB ubhedu, nokuba iibhodi DC okanye mm Wave PCB, kufuneka anti-ukuguga kunye nokhuseleko oxidation. Olu khuselo lunokufezekiswa ngendlela ye-electrolysis kunye neengubo zokuntywila. Bahlala bebonelela ngamaqondo ahlukeneyo obuchule be-weld, ukwenzela ukuba kunye namalungu ahlala-encinci, i-micro-surface mount (SMT), njl., indawo ye-weld epheleleyo inokwakheka. Kukho iindidi ngeendidi zokugquma kunye nonyango olungaphezulu olunokusetyenziswa kwi-PCB copper conductors kushishino. Ukuqonda iimpawu kunye neendleko ezihambelanayo zokwaleka ngalunye kunye nonyango lomphezulu kusinceda senze ukhetho olufanelekileyo ukuze sifezekise umsebenzi ophezulu kunye nobomi benkonzo ende yeebhodi zePCB.

Ukukhethwa kokugqiba kwePCB akuyonkqubo ilula efuna ukuqwalaselwa kwenjongo yePCB kunye neemeko zokusebenza. Indlela yangoku yokuya kupakisho oluxineneyo, i-low-pitch, i-high-speed PCB circuits kunye ne-PCBS encinci, encinci, i-high-frequency PCBS ibeka imingeni kubavelisi abaninzi be-PCB. iisekethe PCB ziveliswa ngokusebenzisa laminates yobunzima ezahlukeneyo ifoyile yobhedu kunye nobukhulu ezibonelelwa abavelisi PCB ngabavelisi eziphathekayo, ezifana Rogers, ngubani ke inkqubo ezi laminates kwiintlobo ngeentlobo PCBS ukusetyenziswa electronics. Ngaphandle kohlobo oluthile lokukhusela umphezulu, abaqhubi kwisekethe baya ku-oxidize ngexesha lokugcinwa. Unyango lomphezulu we-conductor lusebenza njengesithintelo esahlula umqhubi kwindawo engqongileyo. Ayikhuseli kuphela umqhubi we-PCB kwi-oxidation, kodwa inika ujongano lweesekethe ze-welding kunye namacandelo, kubandakanywa ukudibanisa okukhokelela kwiisekethe ezidibeneyo (ics).

Khetha indawo efanelekileyo yePCB

Unyango olufanelekileyo lomphezulu kufuneka luncede ukuhlangabezana nesicelo sesekethe ye-PCB kunye nenkqubo yokuvelisa. Iindleko ziyahluka ngenxa yeendleko zezinto ezahlukeneyo, iinkqubo ezahlukeneyo kunye neentlobo zokugqiba ezifunekayo. Olunye unyango oluphezulu luvumela ukuthembeka okuphezulu kunye nokwahlukaniswa okuphezulu kweesekethe ezixineneyo, ngelixa ezinye zinokudala iiBridges ezingafunekiyo phakathi kwabaqhubi. Olunye unyango olungaphezulu luyahlangabezana neemfuno zomkhosi kunye ne-aerospace, ezifana nobushushu, ukothuka kunye nokungcangcazela, ngelixa ezinye zingaqinisekisi ukuthembeka okuphezulu okufunekayo kwezi zicelo. Apha ngezantsi kukho unyango lomphezulu we-PCB olunokusetyenziswa kwiisekethe ukusuka kwiisekethe ze-DC ukuya kwimillimeter-wave bands kunye nesantya esiphezulu sedijithali (HSD) sesekethe:

●ENIG

●ENEPIG

●HASL

●Isilivere yokuntywiliselwa

●Itoti yokuntywiliselwa

●LF HASL

● OSP

● Igolide eqinileyo ye-Electrolytic

● Igolide ethambileyo edityaniswe ngombane

1.ENIG

I-ENIG, ekwabizwa ngokuba yinkqubo ye-nickel-gold yekhemikhali, isetyenziswa ngokubanzi kunyango lomphezulu wababhexeshi bebhodi yePCB. Le yinkqubo yexabiso eliphantsi ngokwentelekiso eyenza umaleko obhityileyo wegolide edityanisiweyo phezu komgangatho wenikeli kumphezulu we-conductor, ekhokelela kumphezulu osicaba onobuchule bokuweld obulungileyo nakwiisekethe ezixineneyo. Nangona inkqubo ye-ENIG iqinisekisa ukunyaniseka kwe-electroplating (PTH), iphinda ikhulise ukulahleka komqhubi kwi-frequency ephezulu. Le nkqubo inobomi obude bokugcinwa, ngokuhambelana nemigangatho ye-RoHS, ukusuka kumenzi wesiphaluka, ukuya kwinkqubo yendibano yecandelo, kunye nemveliso yokugqibela, inokubonelela ngokhuseleko lwexesha elide kubaqhubi be-PCB, abaninzi abaphuhlisi be-PCB bakhetha unyango oluqhelekileyo lomphezulu.

2.ENEPIG

I-ENEPIG luphuculo lwenkqubo ye-ENIG ngokongeza i-palladium encinci phakathi kwekhemikhali ye-nickel layer kunye ne-golden plating layer. I-palladium layer ikhusela i-nickel layer (ekhusela umqhubi wobhedu), ngelixa i-gold layer ikhusela zombini i-palladium kunye ne-nickel. Olu nyango lomphezulu lufanelekile kwizixhobo zokudibanisa kwi-PCB ekhokelayo kwaye inokusingatha iinkqubo ezininzi zokubuyela kwakhona. Njenge-ENIG, i-ENEPIG iyahambelana ne-RoHS.

3.Isilivere yokuntywiliselwa

Isedimentation yesilivere yeChemical ikwayinkqubo yekhemikhali engeyiyo eye-electrolytic apho iPCB intywiliselwa ngokupheleleyo kwisisombululo seeyoni zesilivere ukubopha isilivere kumphezulu wobhedu. I-coating yesiphumo iyahambelana kwaye ifanayo kune-ENIG, kodwa ayinalo ukhuseleko kunye nokuqina okubonelelwa ngumaleko we-nickel kwi-ENIG. Nangona inkqubo yayo yonyango lomphezulu ilula kwaye ineendleko eziphezulu kune-ENIG, ayifanelekanga ukugcinwa kwexesha elide kunye nabavelisi beesekethe.

4.Itoti yokuntywiliselwa

Iinkqubo zokubeka i-Chemical tin zenza i-tin ebhityileyo yokugquma kumphezulu womqhubi ngokusebenzisa inkqubo ye-multi-step equka ukucoca, i-micro-etching, isisombululo se-asidi prepreg, ukuntywiliselwa kwesisombululo se-tin leaching esingeyo-electrolytic, kunye nokucoca okokugqibela. Ukunyangwa kwe-tin kunokubonelela ngokukhuselekileyo kobhedu kunye nabaqhubi, oku negalelo ekusebenzeni kwelahleko ephantsi yeesekethe ze-HSD. Ngelishwa, itoti etshoniweyo ngokwekhemikhali ayilolona nyango luhlala ixesha elide ngenxa yefuthe letoti enalo kubhedu ekuhambeni kwexesha (oko kukuthi, ukusasazwa kwentsimbi enye ukuya kwenye kunciphisa ukusebenza kwexesha elide komqhubi wesekethe). Njengomchiza wesilivere, itoti yeekhemikhali yinkqubo engenalothe, ethobela iRoHs.

5.OSP

Ifilimu yokukhusela i-organic welding (i-OSP) yinto yokukhusela i-non-metallic yokukhusela ehlanganiswe nesisombululo esisekelwe emanzini. Oku kugqitywa kwakhona kuhambelana ne-RoHS. Nangona kunjalo, olu nyango lomphezulu alunaxesha elide kwaye lusetyenziswa kakuhle phambi kokuba isekethe kunye namalungu adityaniswe kwi-PCB. Kutshanje, ii-membrane ze-OSP ezintsha zivele kwimarike, ekukholelwa ukuba ziyakwazi ukubonelela ngokhuseleko olusisigxina lwexesha elide kubaqhubi.

6.Electrolytic igolide enzima

Ukuphathwa kwegolide enzima yinkqubo ye-electrolytic ngokuhambelana nenkqubo ye-RoHS, enokukhusela i-PCB kunye nomqhubi wobhedu kwi-oxidation ixesha elide. Nangona kunjalo, ngenxa yexabiso eliphezulu lezinto eziphathekayo, ikwayenye yezona zinto zixabisa kakhulu zokugquma komhlaba. Ikwanazo nokuwelda okulambathayo, ukuwelda okulambathayo kokudibanisa unyango oluthambileyo lwegolide, kwaye iyahambelana ne-RoHS kwaye inokubonelela ngomphezulu olungileyo kwisixhobo ukuze ibopheleleke kwiinkokeli zePCB.