Kuyilo lwebhodi yePCB, uyilo oluchasene ne-ESD lwePCB lunokufezekiswa ngokubeka iileya, uyilo olululo kunye neengcingo kunye nofakelo. Ngexesha lenkqubo yoyilo, uninzi lohlengahlengiso loyilo lunokulinganiselwa ekongezeni okanye ekuthabatheni amacandelo ngokuqikelela. Ngokulungelelanisa uyilo lwePCB kunye neengcingo, i-ESD inokuthintelwa kakuhle.

Umbane omileyo wePCB osuka emzimbeni womntu, okusingqongileyo nangaphakathi kwibhodi yombane yePCB izixhobo ziya kubangela umonakalo ohlukeneyo kwitshiphu ye-semiconductor echanekileyo, njengokugqobhoza umaleko obhityileyo wokugquma ngaphakathi kwecandelo; Umonakalo kwisango le-MOSFET kunye namacandelo e-CMOS; CMOS PCB ikopi yokuvala itshixo; i-PN junction kunye ne-short circuit reverse bias; Ibhodi yekopi ye-PCB yesekethe emfutshane yokuphelisa isiphambuka se-PN; Iphepha le-PCB linyibilikisa ucingo lwe-solder okanye i-aluminiyam kwi-PCB sheet inxalenye yesixhobo esisebenzayo. Ukuze kupheliswe ukuphazamiseka kwe-electrostatic discharge (ESD) kunye nomonakalo kwisixhobo sombane, kuyimfuneko ukuthatha amanyathelo ahlukeneyo obugcisa ukukhusela.

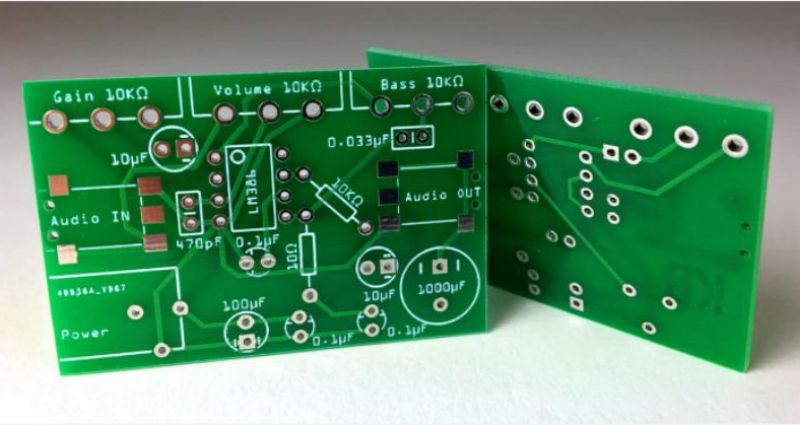

Kuyilo lwebhodi yePCB, uyilo oluchasene ne-ESD lwePCB lunokufezekiswa ngokubeka umaleko kunye noyilo olululo lwePCB iintambo zebhodi kunye nofakelo. Ngexesha lenkqubo yoyilo, uninzi lohlengahlengiso loyilo lunokulinganiselwa ekongezeni okanye ekuthabatheni amacandelo ngokuqikelela. Ngokuhlengahlengisa ubeko lwe-PCB kunye nendlela, ibhodi yokukhuphela ye-PCB inokuthintelwa kakuhle kwi-PCB yokukhuphela ibhodi ye-ESD. Nazi ezinye izilumkiso eziqhelekileyo.

Sebenzisa iileya ezininzi ze-PCB ngokusemandleni, xa kuthelekiswa ne-PCB enamacala amabini, inqwelomoya ephantsi kunye nenqwelomoya yamandla, kunye nesithuba esicwangcisiweyo esicwangcisiweyo somgca womhlaba sinokunciphisa i-impedance yemowudi eqhelekileyo kunye nokudibanisa inductive, ukuze ifikelele kwi-1. /10 ukuya kwi-1/100 yePCB enamacala amabini. Zama ukubeka umaleko ngamnye wesignali ecaleni komgangatho wamandla okanye umaleko womhlaba. Kwi-PCBS yoxinaniso oluphezulu olunamacandelo kuzo zombini iindawo eziphezulu nezisezantsi, zinemigca yoqhagamshelo emifutshane kakhulu kunye neendawo ezininzi zokuzalisa, unokuqwalasela ukusebenzisa umgca wangaphakathi. Kwi-PCBS enamacala amabini, unikezelo lwamandla oludityanisiweyo oluluqilima kunye negridi yomhlaba isetyenziswa. Ikhebula lamandla lisondele kumhlaba, phakathi kwemigca ethe nkqo kunye enqamlekileyo okanye indawo yokuzalisa, ukudibanisa kangangoko kunokwenzeka. Elinye icala legridi yobungakanani bephepha le-PCB lingaphantsi okanye lilingana ne-60mm, ukuba kunokwenzeka, ubungakanani begridi kufuneka bube ngaphantsi kwe-13mm.

Qinisekisa ukuba iphepha ngalinye le-PCB lesekethe licoleke kangangoko.

Beka zonke izihlanganisi ecaleni kangangoko kunokwenzeka.

Ukuba kuyenzeka, yazisa umgca womgca wePCB wamandla ukusuka embindini wekhadi kwaye kude neendawo ezinokuchaphazeleka ngokuthe ngqo kwi-ESD.

Kuzo zonke iileyi ze-PCB ezingezantsi kweziqhagamshelo eziphuma kwi-chassis (ezithanda ukukhokelela umonakalo we-ESD kwibhodi yekopi ye-PCB), beka i-chassis ebanzi okanye imigangatho yokuzalisa ipholygon kwaye uyidibanise kunye nemingxuma kwizithuba ezimalunga ne-13mm.

Beka imingxunya yokuxhoma ye-PCB kwincam yekhadi, kwaye uqhagamshele imingxunya ephezulu nasezantsi ye-PCB sheet engathintelekiyo ujikeleze imingxunya enyukayo emhlabeni we-chassis.

Xa uhlanganisa i-PCB, musa ukusebenzisa nayiphi na i-solder phezulu okanye ezantsi iphedi yephepha le-PCB. Sebenzisa izikrufu ezineewasha zamaphepha ePCB ezakhelweyo ukuze ufumane unxibelelwano oluluqilima phakathi kweshiti/ikhaka lePCB kwimeko yentsimbi okanye inkxaso esemhlabeni.

"Indawo yodwa" efanayo kufuneka imiselwe phakathi komhlaba we-chassis kunye nomhlaba wesiphaluka woluhlu ngalunye; Ukuba kunokwenzeka, gcina isithuba kwi-0.64mm.

Phezulu nasezantsi kwekhadi kufutshane ne-PCB yokukhuphela ibhodi yokufakela imingxunya, qhagamshela i-chassis kunye nomhlaba wesekethe kunye neengcingo ezi-1.27mm ububanzi ecaleni kwe-chassis yocingo lomhlaba rhoqo nge-100mm. Ecaleni kwezi ndawo zoqhagamshelo, iipads ze-solder okanye imingxuma yokuxhoma yofakelo ibekwe phakathi komgangatho we-chassis kunye nomgangatho wesekethe wephepha lePCB. Olu nxulumano lomhlaba lunokusikwa luvuleke ngencakuba ukuze luhlale luvulekile, okanye ukutsiba ngentsimbi yemagnethi/i-high frequency capacitor.

Ukuba ibhodi yesiphaluka ayiyi kufakwa kwimeko yesinyithi okanye isixhobo sokukhusela iphepha le-PCB, musa ukusebenzisa ukuxhathisa kwi-solder kwi-top and bottom case iingcingo zokumisa ibhodi yesekethe, ukuze zisetyenziswe njenge-ESD arc discharge electrode.

Ukuseta iringi ejikeleze isekethe kolu luhlu lulandelayo lwePCB:

1

(2)Qinisekisa ukuba zonke iileya zingaphezulu kwe-2.5mm ububanzi.

(3)Qhagamshela amakhonkco anemingxuma rhoqo nge-13mm.

(4)Qhagamshela umhlaba weringi kumhlaba oqhelekileyo wesekethe yokukopa yePCB enamaleko amaninzi.

(5)Amaphepha ePCB anamacala amabini afakwe kwiindawo ezivaliweyo zetsimbi okanye izixhobo zokukhusela, umhlaba wendandatho kufuneka uqhagamshelwe kumhlaba oqhelekileyo wesekethe. Isiphaluka esingenakunqandwa esinamacala amabini kufuneka sidibaniswe kumhlaba wendandatho, umhlaba wendandatho awukwazi ukugqithwa ngokumelana ne-solder, ukwenzela ukuba i-ringtone isebenze njengentonga yokukhupha i-ESD, kwaye ubuncinane i-gap ye-0.5mm ububanzi ibekwe kwindawo ethile. isikhundla kumhlaba weringi (zonke iileya), ezinokuthi ziphephe ibhodi yekopi yePCB ukwenza iluphu enkulu. Umgama phakathi kwe-wiring yesignali kunye nomhlaba we-ring akufanele ube ngaphantsi kwe-0.5mm.