Unobangela wePCB yePlayithi yomthengisi

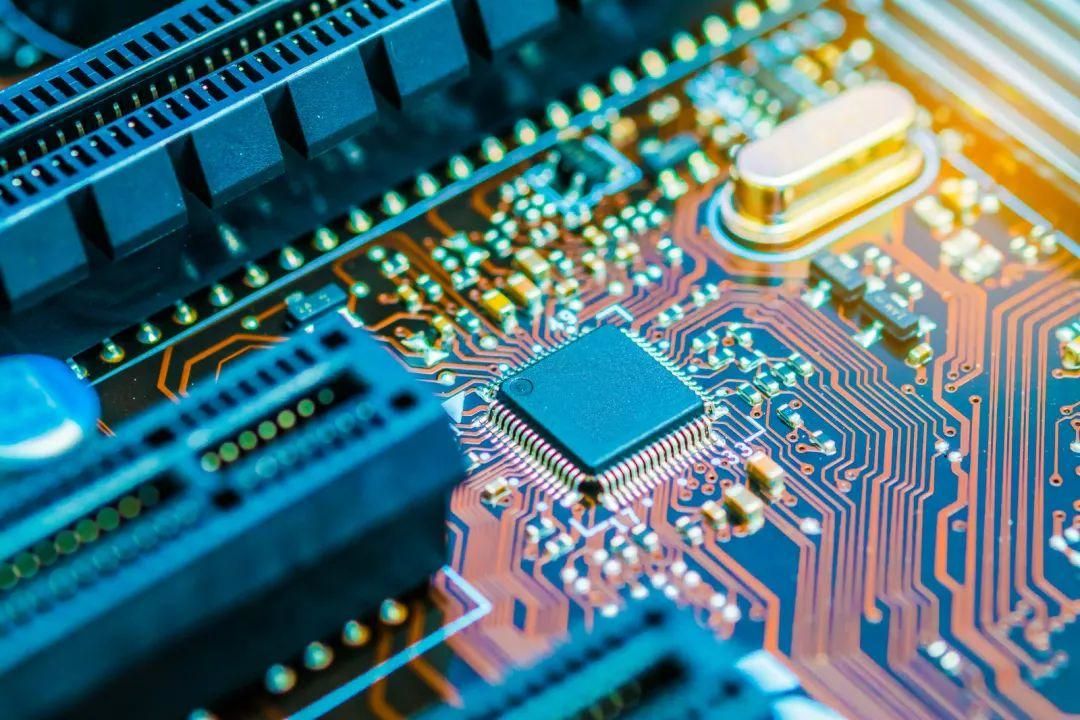

Ibhodi yesekethe ye-PCB kwinkqubo yemveliso, idla ngokudibana nezinye iimpahla, ezinjengeBhob yeBhodi yeBhodi ye-PCB yobhedu i-Word Off (ihlala ithethwa ukuba iphose i-Copper), ichaphazele umgangatho wemveliso. Izizathu eziqhelekileyo zeBhodi yeSekethi yePCB yokuphosa ubhedu zezi zilandelayo:

IMIQATHANGO YENKQUBO YE-PCB yeBhodi

I-1, i-copper foil ye-etching igqithisileyo, i-electrolytic call isetyenziswe kwimarike isetyenziselwe i-foil ye-til ye-70 ye-foil i-70 ye-foil i-70 ye-bill ye-til iphantsi kwe-tiil ye-ash ayizange ibe yi-batch yobhedu.

2. Ukungqubana kwendawo yenzeka kwinkqubo ye-PCB, kwaye ucingo lobhedu lwahlulwe kwi-substratey ngamandla angaphandle. Esi siphoso sibonakala sibonakale njengokuma okanye ukuqhelaniswa kwenqanaba, ucingo lobhedu luya kuba nokugqwetha okubonakalayo, okanye kwicala elinye le-scratch / yefreyithi. Phola inxenye embi yengcingo yobhedu ukuze ubone ubhedu lobhedu, unokubona umbala oqhelekileyo wobhedu, akuyi kubakho ukhukuliseko olubi, ubhedu olubi kakhulu.

I-3, uyilo lwesekethe lwePCB alungqinelani, ngoyilo lwe-mopper yobhedu oluncinci kakhulu, luya kubangela i-etching ethambileyo kunye nobhedu.

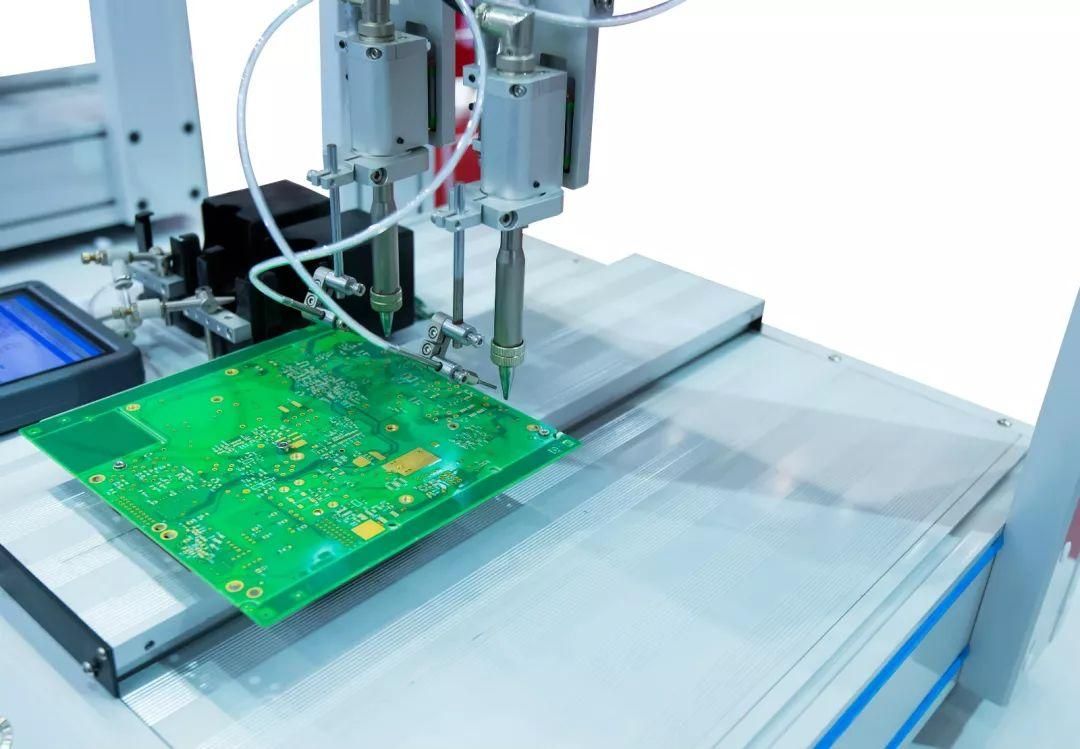

Inkqubo ye-laminate uqiliza

Phantsi kweemeko eziqhelekileyo, lo gama nje ishushu i-subring icandelo le-lamote elingaphezulu kwemizuzu engama-30, i-foreper foil idityaniswa ngokupheleleyo, ke icinezela ngokubanzi ayiyi kuchaphazela amandla obhedi. Nangona kunjalo, kwinkqubo yokufaka i-lamite kunye nokuguqula i-PP, ukuba i-PP Pela okanye i-Popper ye-Moreper Bound Andround Phution, kodwa i-Sporading Copper Palliper Food i-foil isondele.

I-LAMITATE SEAME ST

1, i-elektrolytic yobhedu yobhedu i-poltansed okanye iimveliso ze-Popper, ukuba ixabiso le-pillal le-Work lingazange lisebenze kwi-PCB Pluar kwi-ENGLMIL, icingo le-Popper liza kuwela ngempembelelo yangaphandle. Olu hlobo lwe-wire prest yobhedu yobhedu (oko kukuthi, indawo yoqhakamshelwano kunye nomhlaba) emva kokukhukuliseka kwecala elibonakalayo, kodwa wonke umphezulu wobuqhetseba otyhafileyo uya kuba lihlwempu.

2. Ukulungelelaniswa okungalunganga kwe-copper foil kunye ne-resin: amanye amacala anepropathi ekhethekileyo asetyenziswa ngoku, i-righn ye-vin, i-roleclor esetyenziswayo i-Pinki ilula, ukusebenzisa i-cing yobhedu, ukusebenzisa i-foil yobhedu kunye nokusebenzisa i-foil yobhedu kunye nokusebenzisa i-foil yobhedu kunye nokusebenzisa i-foil yobhedu kunye nokusebenzisa i-foil yobhedu. Xa imveliso ye-lamote isebenzisa i-foil ye-cael kunye nenkqubo ye-resin ayihambelani, kukhokelela kwi-Tship Matling Fiel of Adren A ayonelanga, iplagi iya kubonakala ibiwe ngoconi.

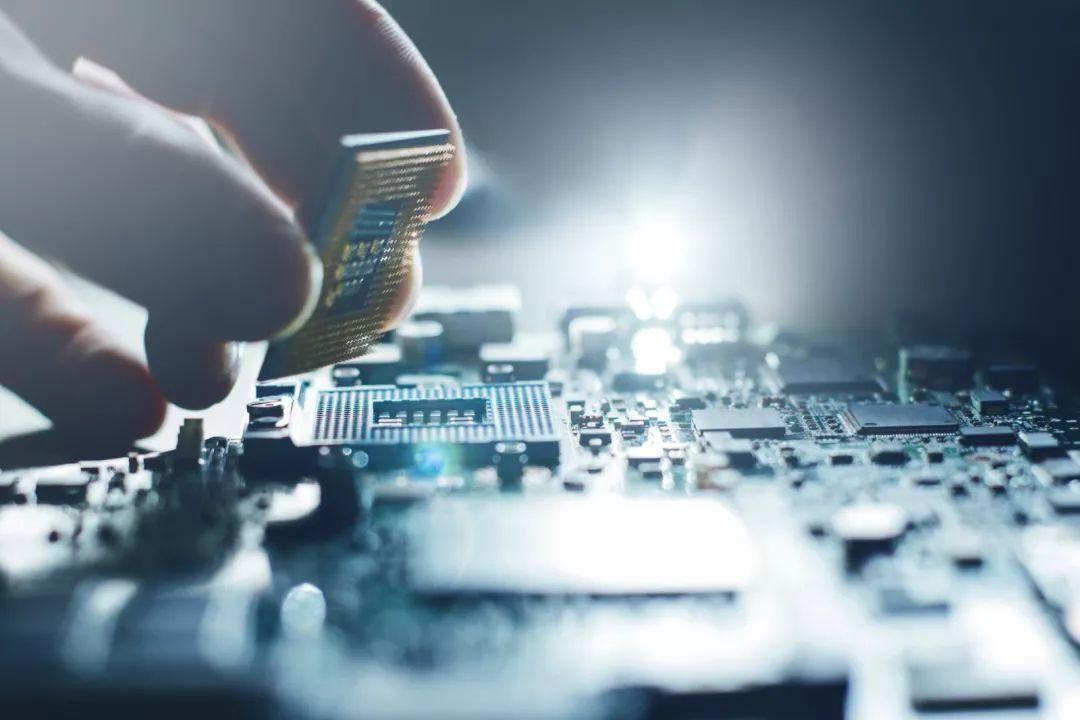

Ukongeza, kunokuba kukuba i-welling engafanelekanga emthengi ikhokelela ekuphulukaneni ne-PAD ye-Welding Tad (ngakumbi iiphaneli ezitshatayo, iiplanga ezihamba kabini, ubushushu obukhawulezileyo, akukho lula ukuwa):

Ukuphinda-phinda indawo yelokhwe iyakukhulisa i-dad;

Iqondo lokushisa eliphezulu lokuthengisela i-iron elithengisa ngokulula ukulila i-pad;

Uxinzelelo oluninzi kakhulu lubekwe yintloko yentsimbi engekho phantsi kwi-pad kunye nexesha elide le-welding liza kuluphala.