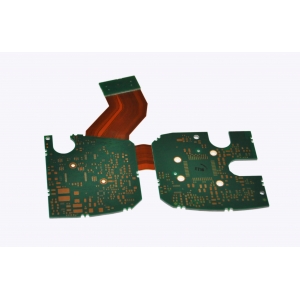

1. PCB ngokusebenzisa umngxuma plating

Kukho iindlela ezininzi zokwakha umaleko we-plating ohlangabezana neemfuno kudonga lomngxuma we-substrate. Oku kubizwa ngokuba kusebenze udonga lomngxuma kwizicelo zamashishini. Abavelisi bayo bebhodi yePCB basebenzisa iitanki ezininzi zokugcina eziphakathi kwinkqubo yokuvelisa. Itanki nganye yokugcina Itanki ineemfuno zayo zokulawula kunye nokugcinwa. I-electroplating etyhutyhayo yinkqubo elandelayo yokwenziwa kwemfuneko yenkqubo yokomba. Xa i-drill bit drills ngokusebenzisa i-foil yobhedu kunye ne-substrate engezantsi, ubushushu obuveliswayo bunyibilikisa i-resin yokwenziwa kwe-insulating synthetic eyenza isiseko se-substrates eninzi, i-resin etyhidiweyo kunye nezinye iziqhekeza zokomba Ifakwe kumngxuma kwaye igqunywe kumngxuma osanda kutyhilwa. eludongeni kwifoyile yobhedu, nto leyo eneneni iyingozi kumphezulu wokutyabeka olandelayo.

I-resin etyhidiweyo iya kushiya umaleko we-axis eshushu kudonga lomngxuma we-substrate, ebonisa ukubambelela kakubi kwii-activators ezininzi, ezifuna ukuphuhliswa kweklasi yeendlela ezifana nokususwa kwebala kunye ne-etchback chemistry. Enye indlela efaneleke ngakumbi kwiprototype yeebhodi zesekethe eziprintiweyo kukusebenzisa i-inki eyilwe ngokukodwa esezantsi-viscosity ukwenza i-adhesive kunye ne-conductive coating ephezulu kudonga lwangaphakathi lomngxuma ngamnye. Ngale ndlela, akukho mfuneko yokusebenzisa iinkqubo ezininzi zonyango lwekhemikhali, inyathelo elilodwa kuphela lesicelo, elilandelwa yi-thermal ukunyanga, linokwenza i-coating eqhubekayo ngaphakathi kuzo zonke iindonga zomngxuma, inokuthi ifakwe ngokuthe ngqo kwi-electroplated ngaphandle konyango olongezelelweyo. Le inki yinto esekwe kwintlaka encamathelayo eyomeleleyo kwaye inokudityaniswa ngokulula kwiindonga ezininzi ezikhazimlisiweyo zomngxunya, ngaloo ndlela isusa inyathelo le-etch back.

2. I-reel yokudibanisa uhlobo olukhethiweyo lweplating

Izikhonkwane kunye nezikhonkwane zezixhobo ze-elektroniki, ezifana neziqhagamshelo, iisekethe ezidibeneyo, ii-transistors, kunye neebhodi ze-FPCB eziguquguqukayo, zonke zifakwe ukuze zifumane ukuchasana kakuhle kunye nokuxhathisa ukubola. Le ndlela yokulinganisa i-electroplating ingenziwa ngesandla okanye izenzekela, kwaye kubiza kakhulu ukukhetha iphini nganye nganye ukuze ibekwe, ngoko ke kufuneka kusetyenziswe i-welding mass. Ngokuqhelekileyo, iziphelo ezibini zefoyile yesinyithi eqengqeleke kubunzima obufunekayo zibethelwa, zicocwe ngeendlela zekhemikhali okanye zemishini, emva koko zikhethwe ngokukhethiweyo njengenickel, igolide, isilivere, irhodium, iqhosha okanye i-tin-nickel alloy, i-copper-nickel alloy. -i-alloy yokukhokela, njl. Kwindlela ye-electroplating ye-plating ekhethiweyo, okokuqala, uluhlu lwefilimu oluchasayo lufakwe kwinxalenye yeplate yensimbi yobhedu engadingeki ukuba ifakwe, kwaye kuphela inxalenye ye-foil yobhedu ekhethiweyo.

3. Ukufakwa kwe-Finger-plating

Intsimbi enqabileyo kufuneka ifakwe kwibhodi yokudibanisa edge, ibhodi edge edge ephumayo yoqhagamshelwano okanye umnwe wegolide ukubonelela ukuchasana okuphantsi kunye nokumelana nokunxiba okuphezulu. Obu buchule bubizwa ngokuba kukutyabeka komgca weminwe okanye ukucwenga kwendawo. Igolide idla ngokutyatyekwa kuqhagamshelo oluphumayo lwesidibanisi somphetho kunye ne-nickel plating kumaleko angaphakathi. Umnwe wegolide okanye inxalenye ephumayo yomphetho webhodi isebenzisa iteknoloji ye-manual okanye ye-automatic plating. Okwangoku, iplagi yegolide kwiplagi yoqhagamshelwano okanye umnwe wegolide ifakwe umakhulu kunye nelethe, amaqhosha acwengisiweyo endaweni yoko.

Inkqubo imi ngolu hlobo lulandelayo:

1. Hlubula i-coating ukuze ususe i-tin okanye i-tin-lead i-coating kwi-contacts ephumayo.

2. Hlanza ngamanzi okuhlamba.

3. Hlikihla ngeebrasives.

4. Ukusebenza kufakwe kwi-10% ye-asidi ye-sulfuric.

5. Ubuninzi be-nickel plating kwi-contacts ephumayo yi-4-5μm.

6. Hlamba kwaye ususe amanzi amaminerali.

7. Unyango lwesisombululo sokungena kwegolide.

8. Ukucwenga kwegolide.

9. Ukucoca.

10. Ukomisa.

4. Ibrashi yokucoca

Yindlela ye-electrodeposition, kwaye ayizizo zonke iindawo ezintywiliselwa kwi-electrolyte ngexesha lenkqubo ye-electroplating. Kule ndlela yokulinganisa i-electroplating, kuphela indawo elinganiselweyo i-electroplated, kwaye ayinayo umphumo kwabanye. Ngokuqhelekileyo, iintsimbi ezinqabileyo zifakwe kwiindawo ezikhethiweyo zebhodi yesekethe eprintiweyo, njengeendawo ezifana nezixhumi zomphetho webhodi. I-brush plating isetyenziswa rhoqo ekulungiseni iibhodi zeesekethe zenkunkuma kwiivenkile zeendibano ze-elektroniki. Gquba i-anode ekhethekileyo (i-anode engasebenziyo ngokwekhemikhali, njengegraphite) kwizinto ezifunxayo (cotton swab) kwaye uyisebenzise ukuzisa isisombululo seplating kwindawo apho kufuneka i-plating.

Fastline Circuits Co.,Limited yingcali: PCB ibhodi yesekethe umenzi wokuvelisa, ikubonelela nge: PCB proofing, batch system board, 1-34 layer PCB board, high TG board, impedance board, HDI board, Rogers board, Manufacture and production of PCB circuit boards iinkqubo kunye nemathiriyeli enje ngeebhodi zemicrowave, iibhodi zerediyo zamaza erediyo, iibhodi zeradar, iibhodi zefoyile yobhedu, njl.