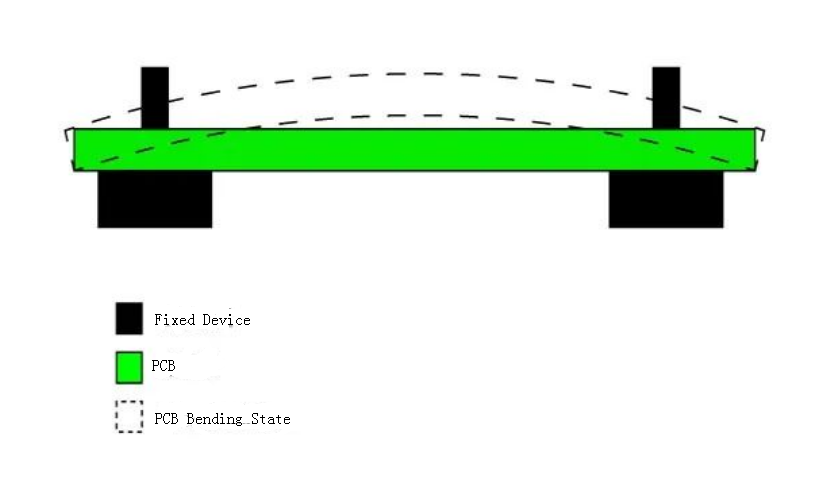

Ebile, PCB e futhumatsa le eona e bua ka ho setse ha boto ea potoloho, e bolelang boto ea pele ea potoloho ea pele. Ha e beoa desktop, lipheletsong tse peli kapa bohareng ba boto e hlaha ho ea holimo hanyane. Ntho ena ena e tsejoa e le PCB e futhumatsang indastering.

Foromo ea ho bala paro ea Boto ea potoloho ke ho beha polasetiki ea potoloho tafoleng le ho lekanya bophahamo ba boto ea potoloho bohareng. Foromo e tjena:

Parpage = bophahamo ba arch / bolelele ba karolo e telele ea PCB * 100%.

Sebaka sa marang-rang sa marang-rang sa boto: Ho ea ka IPC - 6012 (1996 e lumelletsoe ho hlahisa liboto le tse 1,5%. Ka lebaka la bokhoni bo fapaneng ba projeke ea feme e 'ngoe le e' ngoe, ho boetse ho na le liphapang tse itseng tsa litlhokahalo tsa taolo ea PCB. Bakeng sa boto ea boto ea boto ea botoro ba 1,6 ba boto ea potoloho ea boto, e leng lifemerete, ba bangata

Mokhoa oa ho qoba ho futhumatsa board ea potoloho nakong ea tlhahiso?

.

.

.

U ka thibela ho lula u tšoarela joang?

Moralo oa shebileng: Interlayer La sheet ea mohala o ka kopanya o lokela ho ba tse loketseng; Boto ea mantlha ea Corereyer le lakane e halikiloeng e tla etsoa ho morekisi ea tšoanang; Sebaka se hlakileng sa sefofane sa C / s se haufi kamoo ho ka khonehang, le grid e ikemetseng e ka sebelisoa.

2.drying poleiti pele ho tšilafao, ho kenyelletsa mouoane oa metsi poleiti, o felise khatello ea poleiti; Leqephe la ho baka pele u bula, karolo ea kahare le mabaka a mabeli!

3. Tšisetsa ka mahlakore a mangata, tlhokomelo e lokela ho lefuoa ho ea ho hira le ho hlapaola ha pente e hlophisitsoeng e felletseng Poleiti ea mantlha e lokela ho ela hloko tsela ea ho hlora le ho boloka; Tataiso e akaretsang ea leqephe le hlorisang la meriri ke tataiso ea Moride; Tataele e telele ea poleiti ea koporo e meholo ea koporo ke meriodanal; Likarolo tse 10 tsa 4Oz Power Tanpper Tetper

4. Botene ba ho ahlola ha motho a ahlola ka mor'a ho khathala ho bata, ho theola bohale ba tala;

5.Baking poleiti pele ho cheka: likhato tse 150 ka lihora tse 4;

6.Ke ho molemo hore u se ke ua feta brinding brashining grash, ho hloekisoa ha lik'hemik'hale ho khothalletsoa; Khetho e khethehileng e sebelisoa ho thibela poleiti hore e be le ho phutha

7. Kamora ho fafatsa tin ka har'a sephara se futhumetseng kapa seretse sa tšepe se futhumatsang mochesong kapa betheng ea moea o phaphamalang ka mor'a ho hloekisa;