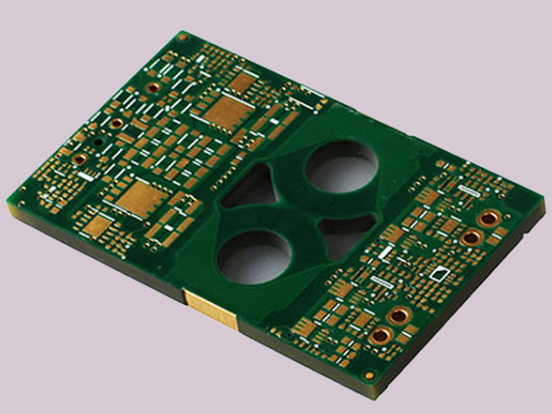

Kenyelletso eaBoto ea Copper PotolohaTheknoloji

(1) Phekolo ea pele ea pele le kalafo ea electroplating

Morero o ka sehloohong oa ho tšoaea kopo ea koporo ea koporo ke ho netefatsa hore ho na le mokato o futhumetseng oa koporo o lekaneng oa koporo ka sekoting ho netefatsa hore boleng ba ho hanyetsa bo fumaneha ka sebopeho se hlokahalang ke ts'ebetso e hlokahalang ke ts'ebetso. Joalo ka plug-in, ke ho lokisa boemo le ho netefatsa matla a khokahano; E le sesebelisoa se nang le sebopeho se nang le sebopeho, masoba a mang a sebelisoa feela ke masoba a bapalang motlakase ka mahlakoreng ka bobeli.

(2) Lintho tsa tlhahlobo

1. Hangata, hlahloba boleng ba metallization ka sekoti, 'me u netefatsa hore ha ho na lesoba le lesoeu, lesoba, jj. Ka sekoting;

2. Lekola hore na ho na le litšila le tse ling tse feteletseng holim 'a substrate;

3. Cheke nomoro, linomoro tsa ho taka, projeke ea ts'ebetso le litlhaloso tsa ts'ebetso ea substrate;

4. Fumana boemo ba ho thaba, litlhokahalo tse holisa le sebaka se apereng seo tanka ea ho tšoaea li ka holang;

5. Sebaka sa likepe le liparathara tsa ts'ebetso li lokela ho hlaka ho netefatsa ho tsitsa le ho se khone ho tiisa hore li-paramente sa ts'ebetso ea electroplating.

6. Ho hloekisa le ho hlophisa likarolo tse mabapi le kalafo, kalafo ea tlhaiso ea ho etsa tharollo e sebetsang;

7. Fumana hore na sebopeho sa metsi a bateng o tšoaneleha le sebaka sa bokantle ba poleiti ea elektrode; Haeba anode e behiloeng se kentsoe ntlheng ena, tšebeliso e boetse e lokela ho hlahlojoa;

8. Hlahloba ho tiea ha likarolo tsa mabitso le ho feto-fetoha ha maemo a phahameng a Voltage le ea hajoale.

(3) taolo ea boleng ba koporo ea koporo ea koporo

1. Bala sebaka se ka nepo 'me u hlahlobe tšusumetso ea ts'ebetso ea ho hlahisa hona joale, ka nepo phetoho ea boleng ba hajoale, le ho netefatsa botsitso ba likarolo tsa projeke ea electroplating;

2. Pele ho electroplating, qala ho sebelisa boto ea ho baloa bakeng sa ho beha liteko, e le hore bate e boemong bo sebetsang;

3. Fumana qeto ea phallo ea hona joale ea hajoale, ebe u tseba tatellano ea lipolanete tse lekanyelitsoeng. Molao-motheo, e lokela ho sebelisoa ho feta haufi le haufi; ho netefatsa ntho e sa tsoakoang ea ho ajoa hona joale ho

4. Ho netefatsa ho tšoana le ho koaloa ka sekoting le ho tsitsipana ha botenya ba koae, ntle le ho sefa ka theknoloji ea ho hlohlelletsa hona joale;

5. Kamehla hlokomela liphetoho tsa hona joale nakong ea ts'ebetso ea elektroplating ho netefatsa ho tšepahala le botsitso ba boleng ba hajoale;

6. Lekola hore na botenya ba lefika la koporo ea koporo le kopana le litlhoko tsa tekheniki.

(4) ts'ebetso ea koporo ea koporo

Ts'ebetsong ea ho bokella compeper ea copper ea koporo, lipampiri tsa ts'ebetso li tlameha ho hlahlojoa hangata, 'me ho lahleheloa ha ho sa hlokahale ebile ho etsoa hangata ka lebaka la mabaka a khothatsang le sepheo. Ho etsa mosebetsi o motle oa ho holisa ts'ebetso ea koporo, linnete tse latelang li lokela ho etsoa:

1. Ho latela boleng ba sebaka seo bo sebelisitsoeng ke k'homphieutha, hammoho le boiphihlelo bo sa feleng bo hlahisitsoeng tlhahisong ea nnete, ho eketsa boleng bo itseng;

2. Ho latela boleng ba hajoale

3. Ha motlakase oa motlakase o fihla metsotso e 5, tlosa karoloana ea ho bona hore na karolo ea motheo e holim 'a sekoti se ka holimo,' me ho molemo hore masoba ohle a na le lustel ea tšepe;

4. Sebaka se itseng se lokela ho bolokoa lipakeng tsa substrate le substrate;

5. Ha polasetiki ea koporo e fihlang e fihla ka nako e hlokahalang ea motlakase, palo e itseng ea hajoale e lokela ho tiisa hore bokaholimo ba substrate bo ke ke ba fifatsoa kapa ba fifalitsoe.

Mehato ya tlhokomelo:

1. Lekola litokomane tsa ts'ebetso, bala litlhoko tsa ts'ebetso 'me u tloaelehile le blueprint ea substrate;

2. Hlahloba bokaholimo ba subrate bakeng sa likheo, li-incuente, likarolo tsa koporo tse pepesitsoeng, jj.;

3. Etsa mosebetsi oa liteko ho latela sesebelisoa sa ho sebetsa ho latela "

4. Lokisetsa lisebelisoa tsa ho lekanya le lisebelisoa tse ling tse sebelisoang ho lekola likarolo tsa sebopeho sa summetric.

5. Ho latela thepa ea lintho tse tala ea sub e sebetsang, khetha sesebelisoa sa lesira se loketseng (curter ea milding).

(5) taolo ea boleng

1. Ho sebelisa tatellano ea pele ea sengoloa ho netefatsa hore boholo ba sehlahisoa bo kopana le litlhokahalo tsa moralo;

2. Ho latela thepa e tala ea boto ea potoloho, hobane ka nepo e ile ea khetha liparathara tsa milling;

3. Ha o lokisa boemo ba boto ea potoloho, o tlotla ho qoba tšenyo ea lesela le maske holim 'a boto ea potoloho;

4. Ho etsa bonnete ba hore boholo ba boholo ba kantle, bo tlameha ho laoloa ka thata;

5. Ha ho bokella le ho kopana le ho kopana, ho lokela ho lekoa ka ho khetheha ho pata senyeha setulong sa substrating se lekanang le boto ea potoloho.