Ho tjheseletsa ha boto ea potoloho ea mekhahlelo e 'meli, ho bonolo ho ba le bothata ba ho khomarela kapa ho tjheseletsa ka mokhoa o hlakileng. 'Me ka lebaka la ho eketseha ha likarolo tse peli tsa lera oa potoloho boto, mofuta o mong le o mong oa likarolo bakeng sa litlhoko tsa tjheseletsa mocheso le tse ling ha li tšoane, e leng se lebisang ho ho eketseha ha bothata ba ho tjheseletsa boto ea potoloho ea lihlopha tse peli, ho akarelletsa le taelo ea ho tjheseletsa. lihlahisoa tse ling li na le litlhoko tse thata.

Mokhoa oa ho tjheseletsa boto e nang le mahlakore a mabeli:

Lokisetsa lisebelisoa le lisebelisoa, ho kenyeletsoa liboto tsa potoloho, likarolo, solder, solder paste, le tšepe ea solder.

Hloekisa bokaholimo ba boto le lithakhisa tsa likarolo: Hloekisa bokaholimo ba boto le liphini tsa motsoako ka sesepa kapa joala ho netefatsa boleng ba welding le ts'epahalo.

Likarolo tsa sebaka: Beha likarolo ho boto ea potoloho ho latela litlhoko tsa moralo oa boto ea potoloho, ho ela hloko tataiso le boemo ba likarolo.

Sebelisa peista ea solder: Tšela pente ea solder ho pad holim'a likaroloana tsa likarolo le boto ea potoloho ho lokisetsa ho cheselletsa.

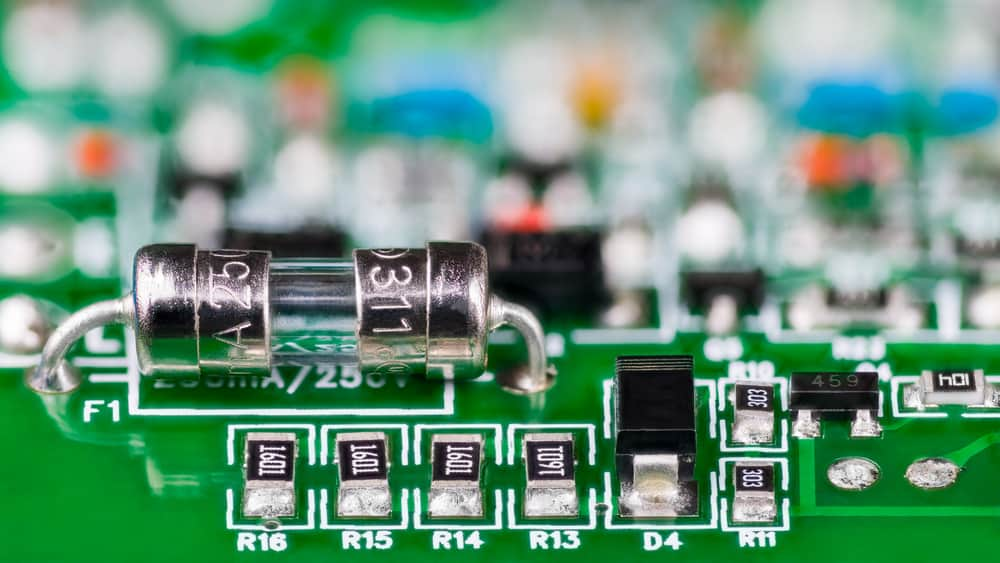

Likarolo tsa welding: Sebelisa tšepe ea solder ea motlakase ho likarolo tsa weld, ela hloko ho boloka mocheso o tsitsitseng le nako, qoba ho futhumatsa ho feteletseng kapa nako ea welding e telele haholo.

Lekola boleng ba tjheseletsa: hlahloba hore na sebaka sa welding se tiile ebile se tletse, 'me ha ho na welding ea sebele, welding leakage le liketsahalo tse ling.

Ho lokisa kapa ho etsa rewelding: Bakeng sa lintlha tsa welding tse nang le mefokolo ea welding, ho lokisoa kapa ho lokisoa hoa hlokahala ho netefatsa boleng ba welding le ts'epahalo.

Keletso ea 1 ea "Circuit Board Welding":

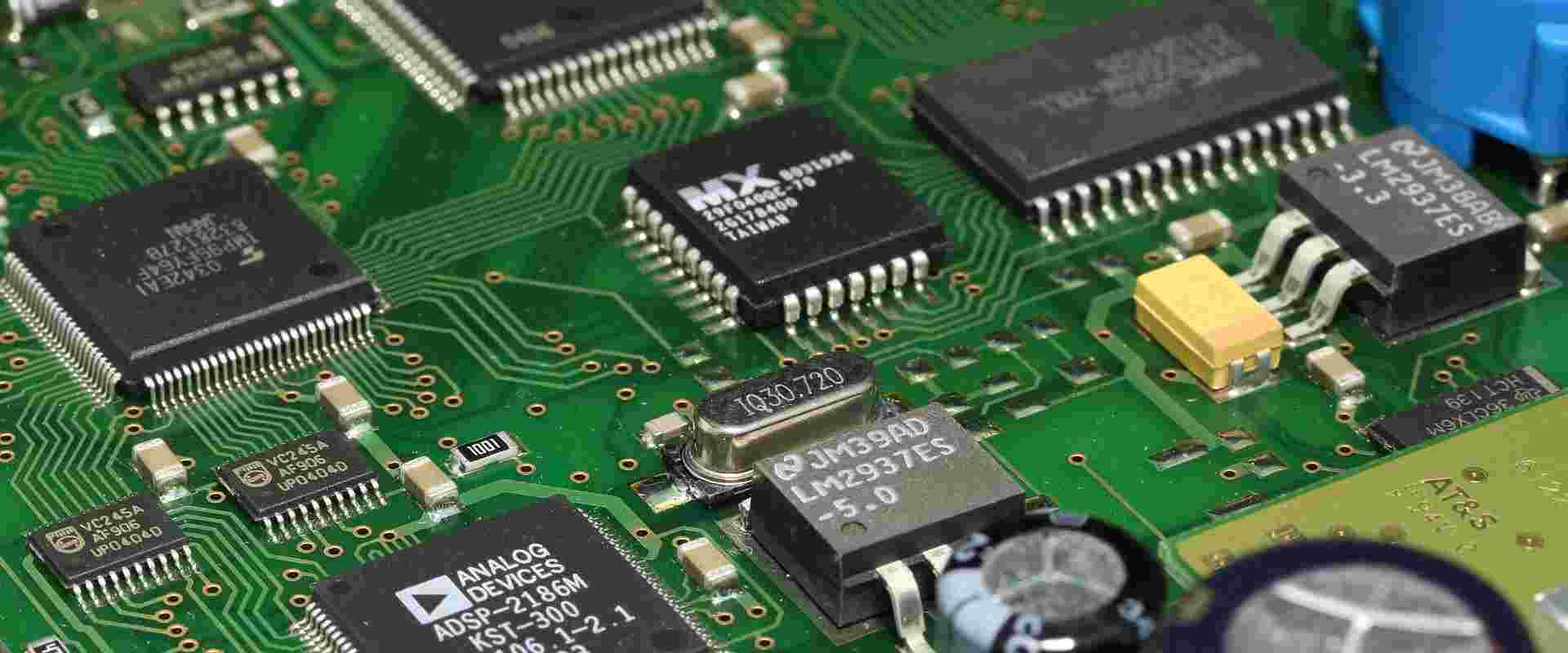

Mokhoa o khethiloeng oa ho tjheseletsa o kenyelletsa: ho fafatsa ka flux, preheating board board, welding e qoela le ho hula welding. Ts'ebetso ea ho roala Flux Ts'ebetso ea ho roala ha flux e phetha karolo ea bohlokoa ho khethoeng ha welding.

Qetellong ea ho futhumatsa le ho tjheseletsa, phallo e lokela ho sebetsa ka ho lekaneng ho thibela ho thehoa ha Bridges le ho thibela oxidation ea boto ea potoloho. Flux spraying Boto e tsamaisoa ke X / Y manipulator holim'a molomo oa phallo, 'me phallo e fafatsoa holim'a boemo ba pcb boto ea tjheseletsa.

Keletso ea 2 ea "Circuit Board Welding":

Bakeng sa microwave tlhoro khetha tjheseletsa ka mor'a hore reflow soldering tshebetso, ke habohlokoa hore flux e ka nepo fafatsa le mofuta oa microporous spray e ke ke ea silafatsa sebaka ka ntle ho solder joint.

Bophara ba sebaka sa micro-spot spraying flux e kholo ho feta 2mm, kahoo boemo bo nepahetseng ba phallo e behiloeng holim'a boto ea potoloho ke ± 0.5mm, e le ho etsa bonnete ba hore phallo e lula e koaheloa karolong ea welding.

Keletso ea 3 ea "Circuit board welding":

tshebetso litšobotsi tsa khetha tjheseletsa ka utloisisa ka ho bapisa le leqhubu soldering, phapang e totobetseng pakeng tsa tse peli ke hore karolo e ka tlaase ea boto oa potoloho ka tjheseletsa maqhubu a qoelisoa ka ho feletseng ka solder mokelikeli, ha a ntse a khetha tjheseletsa, feela libaka tse itseng tse itseng. li kopane le leqhubu la solder.

Kaha boto ea potoloho ka boeona ke mocheso o futsanehileng oa ho fetisa mocheso, o ke ke oa futhumatsa le ho qhibiliha manonyeletso a solder sebakeng se haufi le likarolo le boto ea potoloho ha u cheselletsa.

Flux e boetse e tlameha ho koaheloa pele ho tjheseletsa, 'me ha e bapisoa le solder ea wave, flux e koahetsoe feela karolong e ka tlaase ea boto e lokelang ho kenngoa, ho e-na le boto eohle ea pcb.

Ho phaella moo, ho khetha tjheseletsa ho sebetsa feela ho tjheseletsa ha likarolo tsa plug-in, ho khetha ho tjheseletsa ke mokhoa o mocha, 'me kutloisiso e feletseng ea ts'ebetso ea ho khetha le lisebelisoa tsa thepa e hlokahalang bakeng sa ho kenya letsoho ka katleho.

Ho cheselletsa boto ea mahlakoreng a mabeli ho hloka ho etsoa ho latela mehato e boletsoeng, ho ela hloko polokeho le taolo ea boleng, le ho netefatsa boleng ba welding le ho ts'epahala.

Welding board board e nang le mahlakore a mabeli e hloka ho ela hloko lintlha tse latelang:

Pele ho tjheseletsa, hloekisa bokaholimo ba boto ea potoloho le likhoele tsa likarolo ho netefatsa boleng ba welding le ts'epahalo.

Ho ea ka litlhoko tsa moralo oa boto ea potoloho, khetha lisebelisoa tse loketseng tsa ho tjheseletsa, joalo ka solder, solder paste, jj.

Pele o cheselletsa, nka mehato ea ESD, joalo ka ho roala mehele ea ESD, ho thibela tšenyo ea motlakase ho likarolo.

Boloka mocheso o tsitsitseng le nako nakong ea ts'ebetso ea welding ho qoba ho futhumala ho feteletseng kapa nako e telele haholo, e le hore u se ke ua senya boto ea potoloho kapa likaroloana.

Ts'ebetso ea welding hangata e etsoa ho latela taelo ea lisebelisoa ho tloha tlase ho ea holimo le ho tloha ho tse nyane ho isa ho tse kholo. Ntho ea pele e fanoa ho welding integrated circuit chips.

Ka mor'a hore tjheseletso e phethoe, hlahloba boleng ba tjheseletsa le ho tšepahala. Haeba ho na le mefokolo, lokisa kapa cheld bocha ka nako.

Mosebetsing oa sebele oa tjheseletsa, ho tjheseletsa ha boto ea potoloho e nang le mahlakoreng a mabeli ho hloka ho lumellana ka thata le litekanyetso tsa ts'ebetso le litlhoko tsa ts'ebetso ho netefatsa boleng le ho tšepahala ha tjheseletsa, ha ho ntse ho ela hloko ts'ebetso e sireletsehileng ho qoba kotsi ho eona le ho pota-pota. tikoloho.