HDI: Tekanyo e phahameng ea ho khutsufatsa, ho senyeha ha pelo e se nang mohala, linoko

Ha e ntle hantle, e khuts'oane bakeng sa ho foufala, e hlokomela mokhoa oa ho rekisa pakeng tsa likarolo tse kahare le tse kantle.

E patiloe ka: nako e khuts'oane e ile ea patoa ka, ho lemoha kamano lipakeng tsa karolo e ka hare le karolo e ka hare.

Haholo ka sekoti se senyenyane haholo ka bophara ba 0.05mm ~ 0.15mm).

Lisebelisoa tsa Boto ea HDI

1.HDI PLATE HOPPING RCC, ldpe, FR4

RCC: Bokhutšoanyane bakeng sa Resin Copper

Sebaka sa polokelo ea RCC se na le mokhoa o tšoanang le oa FR-1/4 4 li-maqephe a makhulo a Ntle le ho kopana le litlhoko tsa ts'ebetso tsa khale tsa boto ea multireer ho ea mokhoa oa ho bokella, joalo ka:

(1) Ho tšepahala ho phahameng le ho tšepahala ho matla a ho tšepahala ho matla;

(2) mocheso o phahameng oa khalase (tg);

(3) Deadctric e tlase khafetsa le ho monya metsi a tlase;

(4) Kholiseho e phahameng le matla a phahameng le matla a koporo ea koporo;

(5) Bothusi ba likarolo tsa koena ha ho na ho folisa.

Ka nako e ts'oanang, hobane RCC ke mofuta o mocha oa sehlahisoa ntle le fiber ea khalase, e loketse mohatla o bobebe le plasma, e leng mohala oa multibrazr. Ntle le moo, Osin Copper Foil Copper Foil e na le mobu oa koporo o tšesaane joalo ka 12pm, 18pm, joalo-bonolo, e leng bonolo ho e etsa.

Taba ea boraro, odara ea pele ke efe, PCB ea bobeli ke efe?

Odara ena ea pele, ea bobeli e bua ka palo ea masoba a laser, khatello ea mantlha ea PCB ea ho bapala masoba a laser! Ke litaelo tse 'maloa. Joalokaha ho bontšitsoe ka tlase

1 ,. Ho tobetsa hang ka mor'a masoba a ho cheka == "kantle ho konopo ea CROPPER ==" ebe o tšela masoba

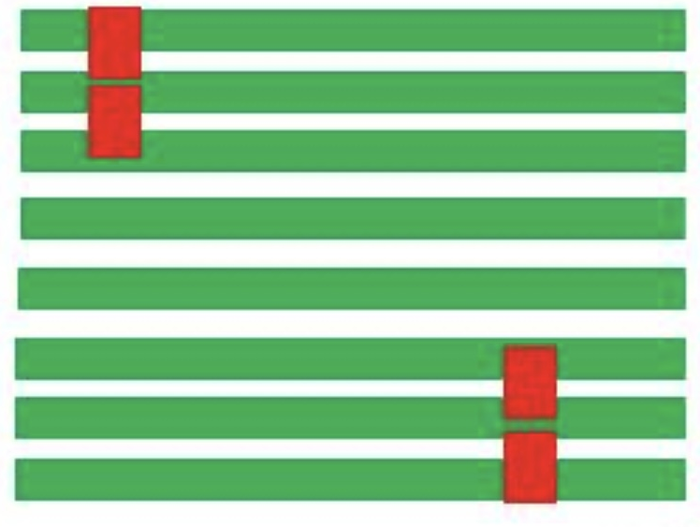

Ena ke mohato oa pele, joalo ka ha ho bontšitsoe setšoantšong se ka tlase

2, kamora ho tobetsa hang le ho chechisa masoba

Ena ke taelo ea bobeli. Ha e le hantle ke taba ea hore na u laetse ka makhetlo a makae ka makhetlo a makae ka makhetlo a makae, ke mehato e mekae.

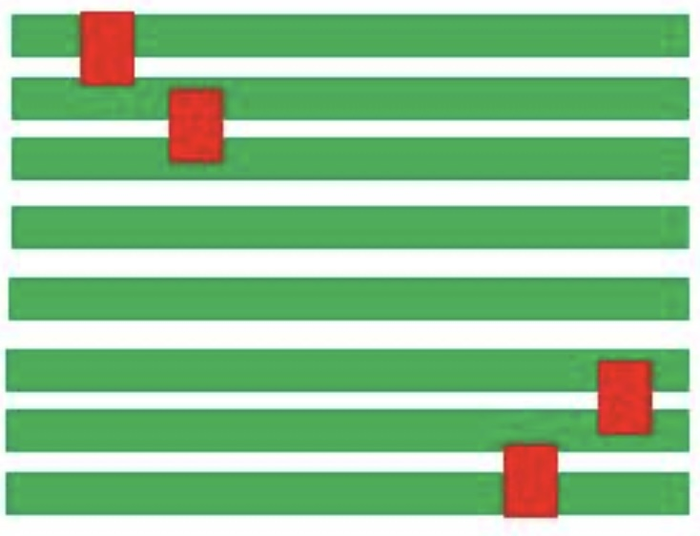

Odara ea bobeli e arotsoe ka masoba a likhohola le ho qhala masoba.

Setšoantšo se latelang ke likarolo tse robeli tsa likoti tsa bobeli tsa masoba, na likarolo tse 3-6 li hatella pele ho ba 2, bokaholimo ba masoba pele. Ebe mekhahlelo ea 1,8 e hatelloa ebe e otla le masoba a laser. Sena ke ho etsa masoba a mabeli a laser. Mofuta oa mofuta ona hobane o hlorisoa, bothata ba ts'ebetso bo tla ba holimo, litšenyehelo li phahame hanyane.

Palo e ka tlase e bonts'a likarolo tse robeli tsa masoba a bobeli, mokhoa ona oa ts'ebetso o tšoana le likarolo tse robeli tse phahameng tsa masoba, hape o hloka ho otla masoba a mabeli habeli. Empa masoba a laser a se ke a ts'oaroa hammoho, bothata ba ho sebetsa ha bo tlase haholo.

Taelo ea boraro, odara ea bone, joalo-joalo.