Maemo a hlokahalang bakeng sapcb ea thekoMabenkeleng a potoloho

1.Tota weld e tlameha ho ba le ho tsitsipana hantle

Chelete e bitsoang ho e-na le ts'ebetso ea ALLYA hore boitsebiso ba tšepe bo tenoa, 'me lesole le ka theha motsoako o motle mocheso o nepahetseng. Ha se libaka tsohle tse nang le ho beleha hantle. Tse ling tsa tšepe, tse kang chromium, molybem Libuka tse ling, tse kang koporo, koporo, joalo-joalo, joalo-joalo, joalo-joalo. Nakong ea likhahla, mocheso o phahameng o etsa filimi e ngata ea ho theha setlamo sa tšepe, e amang sengobe sa boitsebiso. Bakeng sa ho ntlafatsa letso, tin e hlahang, lipente tse ling le mehato e meng li ka sebelisoa ho thibela oxidation ea lintho tse phahameng.

2. Theotoloha e tlametsoe ho bolokoa

Bakeng sa ho ba le motsoako o motle oa lesela le olong, bokaholimo bo tlametsoeng bo tlameha ho bolokoa bo hloekile. Le bakeng sa boima ba li-fompiwa tsa mekhabiso e metle, li-folfi tsa methapo e kotsi ea ho kolobisoa ke ho kolobisoa ka lebaka la ho boloka le ho boloka thepa kapa litšila. Filimi ea litšila e tlameha ho tlosoa pele u songoa, ho seng joalo e ka se tiisoe. Metsoako e bonolo ea oxide ea libaka tsa tšepe e ka tlosoa ke ho feptjoa. Maqhubu a tšepe a nang le oxidation e matla a lokela ho tlosoa ka metsamao e matla kapa ea lik'hemik'hale e kang ho hlafuna kapa ho thothomela.

3.use Flux e loketseng

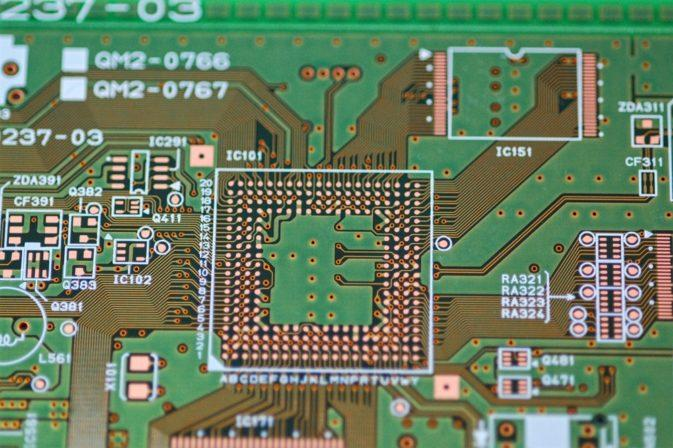

Ts'ebetso ea flux ke ho tlosa filimi ea oxide holim'a lefatše. Mekhoa e fapaneng ea ho bopa e hloka mafura a fapaneng, enterl-Chromium e anyesang, tšepe e nang le mabele, aluminium le lisebelisoa tse ling. Ho thata ho bala ho se be le malaka a khethehileng a khethehileng. Ha ho palama lihlahisoa tsa elektroniki joalo ka liboto tsa potoloho tse hatisitsoeng le ho boloka metsi a tšepahalang le a tsitsitseng hangata li sebelisoa. Ka kakaretso, joala bo sebelisoa ho tlosa Rosin Metsi a Roshan.

4. Buka e lokela ho futhumatsoa mochesong o nepahetseng

Nakong ea walth, mosebetsi oa matla a futhumatsang o qhibilihe le ho futhumatsa ntho e lekaneng ho kena ka har'a tšepe ho fumana matla a tšepe a holim 'a tšepe hore o thehe liallo. Haeba mocheso o mongata o tlase haholo, o tla ba kotsi ho kenella ha liathomo tsa rekise, a etsa hore ho se khone ho theha sello, 'me ho bonolo ho theha lesole la bohata. Haeba mocheso o tenang o phahame haholo, o tla ba boemong bo seng tutense, o potlakisa ho bolaoa le sekhahla sa sephara sa ho senyeha, le maemong a boima, se ka baka lipampiri tsa potoloho ea potoloho ea potoloho ea potoloho. Se hlokang ho totobatsoa ke hore ha se lesole feela a ka futhumatsa ho qhibiliha, empa sesepa sa eona se lokela ho futhumatsa mocheso mochesong o ka qhileng.

5. Nako e loketseng

Nako e bua ka nako e hlokahalang bakeng sa liphetoho tsa 'mele le tsa lik'hemik'hale nakong ea ho bopa hohle. Ho kenyelletsa nako ea hore tšepe e fuoa monyetla oa ho fihla mocheso oa ho hlafuna, nako ea ho qhibiliha ha lesole, nako ea feme ea ho sebetsa le nako ea letlooa ho ea sebetsa. Kamora hore mocheso oa ho hlanya o khethoa, nako e loketseng e loketseng e lokela ho ikemisetsa ho latela sebopeho, tlhaho le litšobotsi tsa likarolo tse lokelang ho beoa. Haeba nako ea ho soasoa e telele haholo, likarolo kapa ho bopa li tla senyeha habonolo; Haeba nako ea ho soasoa e khuts'oane haholo, Litlhoko tsa ho roala li ke ke tsa kopana. Ka kakaretso, nako e ngata ea hore lesole le leng le le leng le kopaneng le le boima le se fetang metsotsoana e 5.