Waxaa jira noocyo badan oo PCB ah oo loo marayo daloolka daloolka, iyo daloollo kaladuwan ayaa loo dooran karaa iyadoo loo eegayo shuruudaha codsiyada kala duwan iyo shuruudaha naqshadeynta. Waxyaabaha soo socdaa waxay faahfaahin ka noqon doonaan furitaanka PCB-ka caadiga ah ee PCB ee loo maro godad iyo farqiga u dhexeeya PCB iyada oo loo marayo godad iyo godad.

一, nooca PCEERURKA PCB ee god

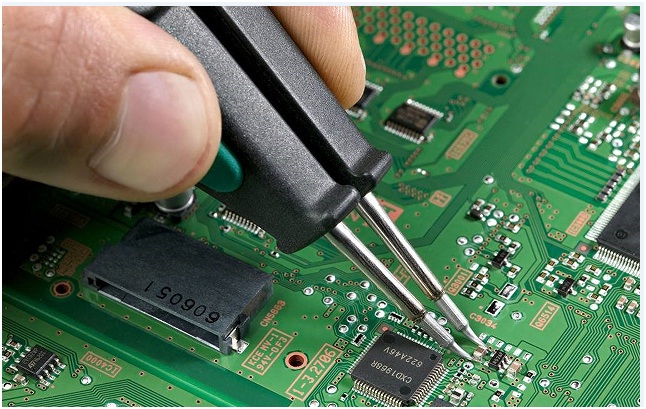

1. Daloolka caadiga ah (PCB Standard Standard): Caadi ahaan naqshadda PCB, god wareeg ah oo leh aperture oo ka weyn ama le'eg 0.4mm waxaa loo yaqaannaa aperture-ka caadiga ah. Aperture-ka Tani waxaa badanaa loo isticmaalaa in lagu hubiyo guddiga PCB iyo qeybta isku xirka PIN.

2. Tagaag Micro-ka Micro Aperture: Apritate-ka Micro wuxuu tixraacayaa god wareeg ah oo leh dhexroor ka yar 0.4mm. Iyada oo la sii kordhayo miniarization-ka kor u qaadista aaladda elektiroonigga ah, waxaa jira baahi sare oo loo qabo qaabeynta PCB, sidaa darteed calaamadaha micropre-ka ayaa si tartiib tartiib ah u noqda. Codsiyada microrapitauture waxaa ku jira aaladaha yaryar ee elektiroonigga ah sida laptops iyo taleefannada gacanta.

3. Dalool lagu xiray (god xargaha ah)

二, farqiga u dhexeeya PCB god iyo god

PCB iyada oo loo marayo god iyo godku way ku kala duwan yihiin isticmaalka guddiga PCB, badiyaa waxaa jira kala duwanaanshaha soo socda:

1. Ujeeddada naqshadeynta PCB: Godad PCB ayaa si ula kac ah loogu keydiyey godad ku yaal qaabeynta, waxaana loo baaraandegi doonaa si loogu xiro ugu yaraan laba lakab oo PCB ah. Iyada oo loo adeegsado godad waxaa loogu talagalay in lagu xiro lakab gaar ah ama qayb, oo meeshooda lagu go'aamiyo shuruudaha qaabeynta.

2, Xiriirinta Calaamadaha (Xiriirka Calaamadaha): PCB-ga godku waa PIN-ka Sint-ka laga bilaabo hal lakab ilaa lakab kale si loo gaaro gudbinta calaamadaha. Iyada oo loo adeegsado godad ayaa inta badan loo isticmaalaa in lagu hagaajiyo alwaaxda PCB iyo qaybaha waxayna bixiyaan taageero farsamo.

3. Habka wax soo saarka: godadka PCB waxaa lagu daaweyn doonaa aalado gaar ah iyo agab inta lagu gudajiro nidaamka wax soo saarka, badiyaa iyadoo la adeegsanayo korantada si loo kordhiyo cudurka korantada. Daloolka iyada oo loo marayo si fudud, badiyaa waxay u baahan tahay oo keliya in lagu farsameeyo god ku habboon booska.

4. Taageerada qaab dhismeedka: Jiritaanka godadka PCB wuxuu kordhin karaa xasilloonida dhismayaasha iyo adkaynta ee guddiga PCB, oo door ka ciyaara. In kasta oo daloolka ay sidoo kale kordhin karto heer gaar ah oo adag, ujeedadeeda ugu weyn ayaa ah in la bixiyo howlo go'an oo iskuxiran.

Marka la soo koobo, kumbuyuutarka PCB dhex mara god waxaa ku jira aperture-ka caadiga ah, microraperture iyo dalool xarig leh. Farqiga u dhexeeya PCB-ga iyada oo loo marayo godad iyo godad ayaa inta badan lagu muujiyaa ujeedada naqshadeynta, iskuxirka calaamadda, tikniyoolajiyadda wax ka qabashada iyo taageerada qaab dhismeedka. Naqshadeynta PCB iyo shuruudaha Golaha waxaa lagu buuxin karaa iyadoo la dooranayo noocyo Aperture oo kala duwan oo adeegsanaya godad ku habboon ama godad.