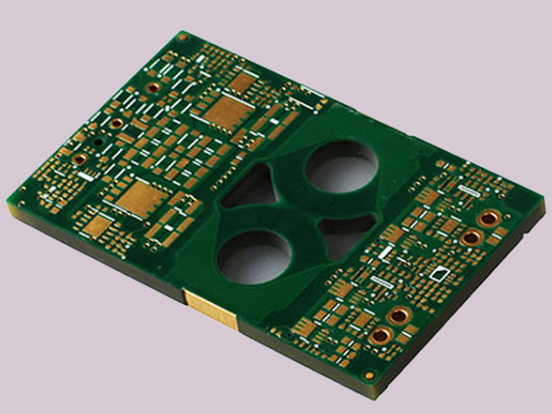

HordhacGuddiga Qabow ee BuluudkaCilmi farsamo

(1) diyaarinta hordhaca ah iyo daaweynta elektaroonigga ah

Ujeedada ugu weyn ee ah qaro weyn ee xarkaha naxaas ah ayaa ah in la hubiyo in lakabka saqafka naxaas ah oo ku filan oo godka ah si loo hubiyo in qiimaha iska caabbinta uu ku jiro tirada ay u baahan tahay. Sida wax lagu dhejiyo, waa in la xaliyo booska oo loo hubiyo xoogga xiriirka; Sida aalad dusha sare ah, godad qaarkood ayaa loo isticmaalaa oo keliya godad, oo ka ciyaara doorka korantada labada dhinac.

(2) waxyaabaha kormeerka

1. Inta badan hubi tayada metlinlis-ka ee godka, oo hubi in aan xad lahayn, burr, dalool madow, dalool, iwm. Godka;

2. Hubi haddii ay jiraan wasakh iyo xad-dhaafyo kale oo dusha sare ah ee substrate;

3. Hubi lambarka, lambarka sawir, dukumiintiga nidaamka iyo sharraxaadda habraaca ee substrate;

4. Soo ogow booska fuulitaanka, shuruudaha kor u kaca iyo aagga dahaarka ah ee ah in haanta taakulku dhalayso;

5. Aagga xanta iyo cabirka nidaamka waa inuu caddeeyaa si loo hubiyo xasilloonida iyo suuragalnimada xuduudaha tilmaan-bixiyaha korantada;

6. Nadiifinta iyo diyaarinta qaybo ka mid ah anshaxeed, daaweynta kowaad ee korantada ee xallinta xallinta firfircoonida;

7. Go'aaminta bal in halabuurka dareeraha qubeyska uu yahay mid uqalma iyo aagga dusha sare ee saxanka electrode; Haddii anticaska laf-dhabarka lagu rakibay sadarka, isticmaalka sidoo kale waa in la hubiyaa;

8. Hubi adkeynta adag ee la xiriirka iyo isdameeyaha isbeddelka korantada iyo hadda.

(3) xakamaynta tayada ee xayiraadda naxaas qaro weyn

1. Si sax ah u xisaabiyo aagga shaacinta oo tixraac saameynta geedi socodka wax soo saarka dhabta ah ee hadda jira, si sax ah u go'aamiso qiimaha loo baahan yahay ee nidaamka korantada, oo la hubiyo xasilloonida xuduudaha habka elektaroonigga ah;

2. Ka hor inta aan korantada lahayn, marka hore u adeegso guddiga dib-u-dejinta ee xanta tijaabada, si qubayshu ay ku jirto xaalad firfircoon;

3. Go'aanso jihada qulqulka guud ee guud, ka dibna go'aamiya amarka taarikada la laalaadayo. Mabda 'ahaan, waa in loo istcimaalo meel fog; Si loo hubiyo isku-darka ah ee qaybinta hadda jirta ee dusha sare;

4. Si loo hubiyo isku-darka dahabka godka iyo joogteynta dhumucda ee ka daadanaya dahaarka, marka lagu daro tallaabooyinka teknolojiyada ee kareyda iyo shaandhaynta, sidoo kale waa lagama maarmaan in la isticmaalo xiisaha jira ee hadda;

5. Si joogto ah ula soco isbeddelada hadda socda inta lagu gudajiro geedi socodka korantada si loo hubiyo isku halaynta iyo xasilloonida qiimaha hadda jira;

6. Hubi in dhumucda caqabadda naxaasta naxaasta ah ee godka godka uu buuxiyo shuruudaha farsamada.

(4) Habka Taajeejinta naxaasta

Inta lagu gudajiro geedi socodka qaddarka naxaas ah, cabiraada geedi socodka waa in si joogto ah loola socdaa, iyo khasaaraha aan loo baahnayn waxaa sababa sababo la xiriira sabab iyo ujeedo darteed. Si loo sameeyo shaqo wanaagsan oo ka mid ah dhumucda geedi socodka tufaax naxaas ah, dhinacyada soo socda waa in la sameeyaa:

1. Marka loo eego qiimaha aagga ee lagu xisaabiyo kombiyuutarka, oo ay weheliso khibradda joogtada ah ee ku urursan soosaarka dhabta ah, kordhinta qiime cayiman;

2. Sida laga soo xigtay qiimaha hadda la xisaabiyey, si loo hubiyo in lakabka lakabka ee godka, waxaa lagama maarmaan ah in la kordhiyo qiime cayiman, oo ah, ka dibna ku soo noqo qiimaha asalka ah waqti gaaban gudaheeda;

3. Marka elektaroonigga ah ee guddiga wareega ee guddiga wareega ay gaarayaan 5 daqiiqo, soo qaado substrate si aad u fiiriso bal in lakabka naxaasta dusha sare iyo derbiga gudaha ee godka oo dhami ay leeyihiin in dhammaan godadku ay leeyihiin luster bir ah;

4. Masaafada qaarkood waa in lagu hayaa inta udhaxeysa substrate iyo substrate;

5. Marka bookshinka cagaaran ee qaro weyn uu gaaro waqtiga korantada ee loo baahan yahay, xaddidan oo hadda jira waa in la ilaaliyaa inta lagu jiro ka saarista substrate si loo hubiyo in dusha sare iyo godadka substrate-ka aan la madoobin doonin ama madow.

Ka taxadaritaan:

1. Hubi dukumiintiyada nidaamka, aqri shuruudaha hanaanka oo yaqaanaan qaabeynta mashiinnada mashiinka;

2. Ka hubi dusha sare ee substrate-ka xoqidda, tigidhada, oo ay soo bandhigeen qaybaha naxaasta ah, iwm .;

3. Qaado socodsiinta tijaabada ah ee ku saabsan diskiga farsamada gacanta ee ku saabsan diskiga farsamada gacanta, samee kormeerka hore, ka dibna ka shaqee dhammaan shaqooyinka shaqada ka dib markii la kulmo shuruudaha teknolojiyadda;

4. U diyaari aaladaha cabbiraadda iyo aaladaha kale ee loo isticmaalo in lagu kormeero cabirrada joomatari ee substrate;

5. Marka loo eego guryaha ceyriinka ah ee sunta ka shaqeynta substrate-ka, xulo aaladda ku habboon dhalaalka (goynta goynta).

(5) xakamaynta tayada

1. Si adag u dhaqan geli Nidaamka Baadhitaanka Article ee ugu horreeya si loo hubiyo in cabirka sheyga uu buuxiyo shuruudaha naqshadeynta;

2. Marka loo eego qalabka ceyriinka ah ee guddiga wareega, si macquul ah u xulo cabbirrada geedi socodka dhalaalka ah;

3. Marka la hagaajinayo booska guddiga wareega, si taxaddar leh u xaji si aad uga fogaato waxyeelada lakabka iibinta iyo maaskarada gacanta ee dusha sare ee guddiga wareega;

4. Si loo hubiyo in la xakameeyo cabirrada dibedda ee substrate, saxsanaanta mawqifka waa in si adag loo xakameeyaa;

5. Markii la kala diro iyo isu imaatinka, fiiro gaar ah waa in la bixiyaa si loo xajiyo lakabka saldhiga ee substrate-ka si looga fogaado waxyeelada lakabka daboolka dusha sare ee guddiga wareega.