Howsha SMTwaa tikniyoolajiyad dhawr ah oo tikniyoolajiyad ah oo loogu talagalay ka shaqeynta ku saleysan PCB. Waxay leedahay faa'iidooyinka saxda ah ee saxda ah ee saxda ah iyo xawaaraha degdega ah, sidaa darteed waxaa qaatay soo-saareyaal badan oo elektiroonig ah. Nidaamka ka-hortagga SMT ee SMT wuxuu ka kooban yahay shaashadda xariir ama xabagta xabagta, kor u qaadida ama daadinta, nadiifinta iibinta, nadiifinta, geedi socodka, iwm.

1.Screen daabacan

Qalabka hore ee ku yaal khadka soo-saarka ee SMT waa mashiin daabacan oo SMT ah, oo howlahooda ugu weyn ay tahay in lagu daaweeyo suufka koollada ama dhejiska xargaha PCB-ga si loogu diyaariyo qaybaha qalabka.

2. Bixinta

Qalabka ku yaal dhamaadka hore ee safka wax soo saarka SMT ama gadaashiisa mashiinka kormeerka waa ku-dir xaliyaal. Hawsha ugu weyn ayaa ah in lagu tuuro xabagta meesha go'an ee PCB, ujeedkuna waa in lagu hagaajiyo qaybaha PCB.

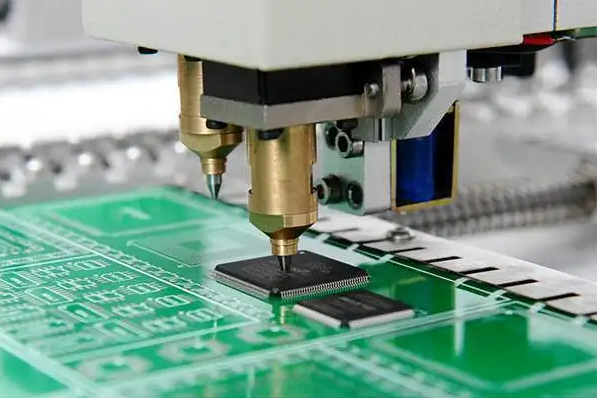

3. Meelaynta

Qalabka ka dambaysa mashiinka daabacaadda shaashadda shaashadda ee SMT ee khadka soo-saarka SMT waa mashiin meeleyn, kaas oo loo isticmaalo in si sax ah uruurinta dusha sare ee dusha sare loo qaado meel go'an oo ku taal PCB.

4. Daaweynta

Qalabka mashiinka meelaynta ee khadka soo-saarka SMT waa foornada la daaweynayo, oo shaqadooda ugu weyn ay tahay in la dhalaalo xabagta meelaynta, si ay dusha sare u kaxeeyaan dusha sare iyo gudiga PCB-da ayaa si adag isugu xidhan.

5. Kufajinta iibinta

Qalabka mashiinka meelaynta ee khadka soo-saarka SMT waa foornada wax laga beddelo, kaas oo shaqadooda ugu weyn ay tahay in la dhaleeceeyo koollada gacanta si ay dusha sare u kaxeeyaan iyo gudiga PCB-da ayaa si adag isugu xidhan.

6. Ogaanshaha

Si loo hubiyo in tayada iibinta iyo tayada golaha ee guddiga PCB ee la soo ururiyey ee loo yaqaan 'PCB Pices Pices', Machoscopes-ka, kormeerayaasha baarista ee duulaya, kormeerka baarista otomatiga (AOI), nidaamyada kormeerka raajada iyo qalabka kale ayaa loo baahan yahay. Hawsha ugu weyn waa in la ogaado in guddiga PCB ay leeyihiin cilado ay ka mid yihiin iibinta Virtual, iibinta, iyo dillaacyada.

7. Nadiifinta

Waxaa jiri kara haraaga haraaga ee waxyeelada u leh jirka bini-aadamka sida flux guddiga PCB ee la soo ururiyey, kaas oo u baahan in lagu nadiifiyo mashiinka nadiifinta.