War

-

Xusuusnow tabaha dayactirka ah, waad hagaajin kartaa 99% ee ku dhaca PCB guuldaradii

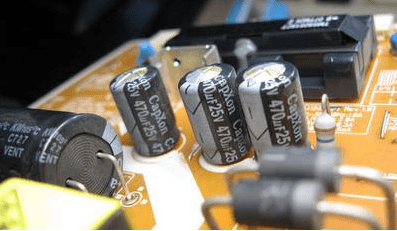

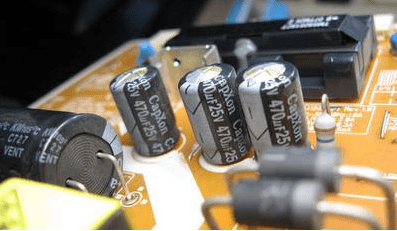

Guul darrooyinka ay ka dhashaan waxyeellada ku soo gaadhay dameerka ayaa ah kuwa ugu sareeya qalabka elektiroonigga ah, iyo waxyeelada dafaradaha elektaroonigga ah ayaa ugu badan. Waxqabadka uumiga ee dameeyuhu waa sida soo socota: 1. Awoodda ayaa sii yaraanaysa; 2. Guul dhameystiran oo karti leh; 3. Biyo daadis; 4. Wareegga gaagaaban. Capacitors ciyaara ...Akhri wax dheeraad ah -

Xalka nadiifinta ee warshadaha korantada ay tahay inay ogaato

Maxaa daahirinaya? 1. Inta lagu gudajiro isticmaalka xalka korantada, alaabada dabiiciga ah waxay sii wadaan inay urursadaan 2. TOC (Isugeynta qiimaha sunta dabiiciga ah), kaasoo horseedi doona in laga helo 3. Cilladaha korantada ...Akhri wax dheeraad ah -

Qiimaha fash-ka-naxaas ah ayaa kor u kacaya, iyo ballaarinta waxay noqotay is afgarad ka jirta warshadaha PCB

Soo noqnoqoshada sare ee maxalliga ah iyo xawaaraha waxsoosaarka sare ee xarkaha sare ee shaashadda ah kuma filna. Wershadaha Foloper-naxaas waa caasimada, tikniyoolajiyadda, iyo warshadaha kartida leh ee leh carqaladaha sare ee gelitaanka. Sida ku xusan codsiyada hoos udhaca ee kala duwan, alaabada naxaasta ah ayaa loo qaybin karaa ...Akhri wax dheeraad ah -

Waa maxay xirfadaha naqshadeynta ee OP Amp Amp Ampit PCB?

Guddiga oo daabacan (PCB) Wires wuxuu door muhiim ah ka ciyaaraa wareegyada xawaaraha sare, laakiin badanaa waa mid ka mid ah tillaabooyinka ugu dambeeya ee nidaamka naqshadeynta wareega. Dhibaatooyin badan ayaa ka jira fiilooyinka xawaaraha sare ee xawaaraha sare, iyo suugaan badan ayaa laga qoray mowduucan. Qodobkaani wuxuu inta badan ka hadlayaa fiilooyinka ...Akhri wax dheeraad ah -

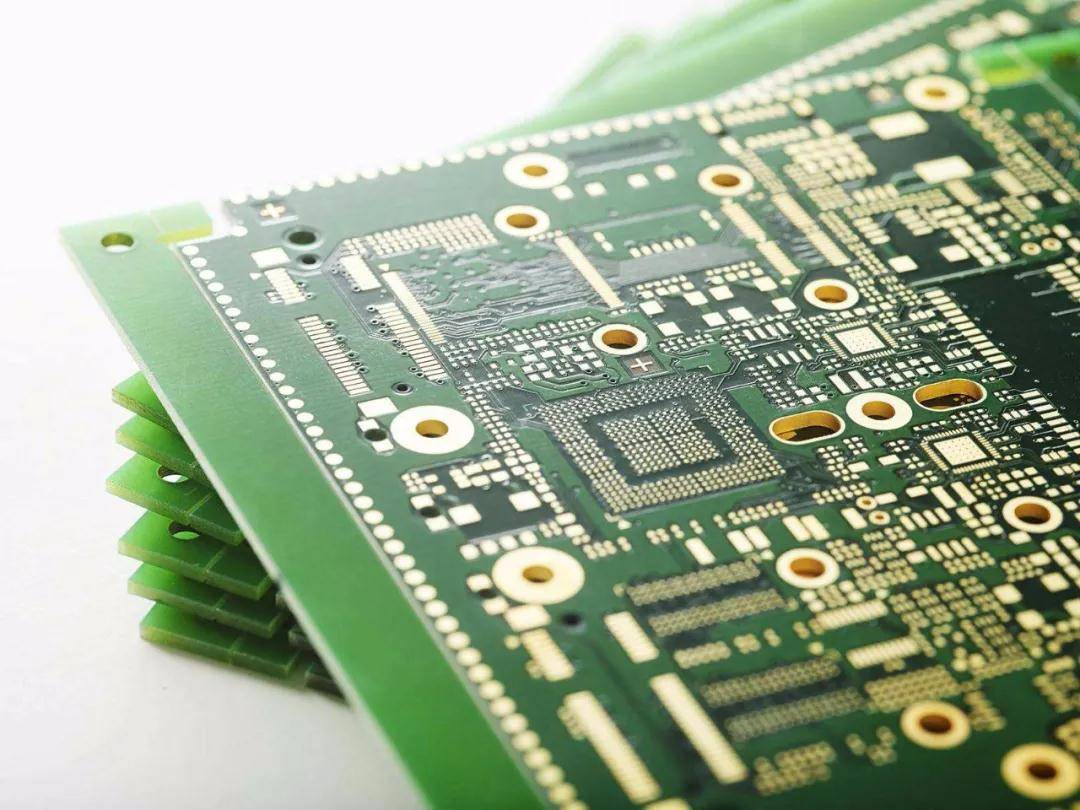

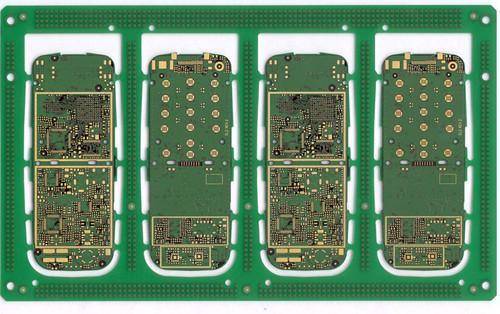

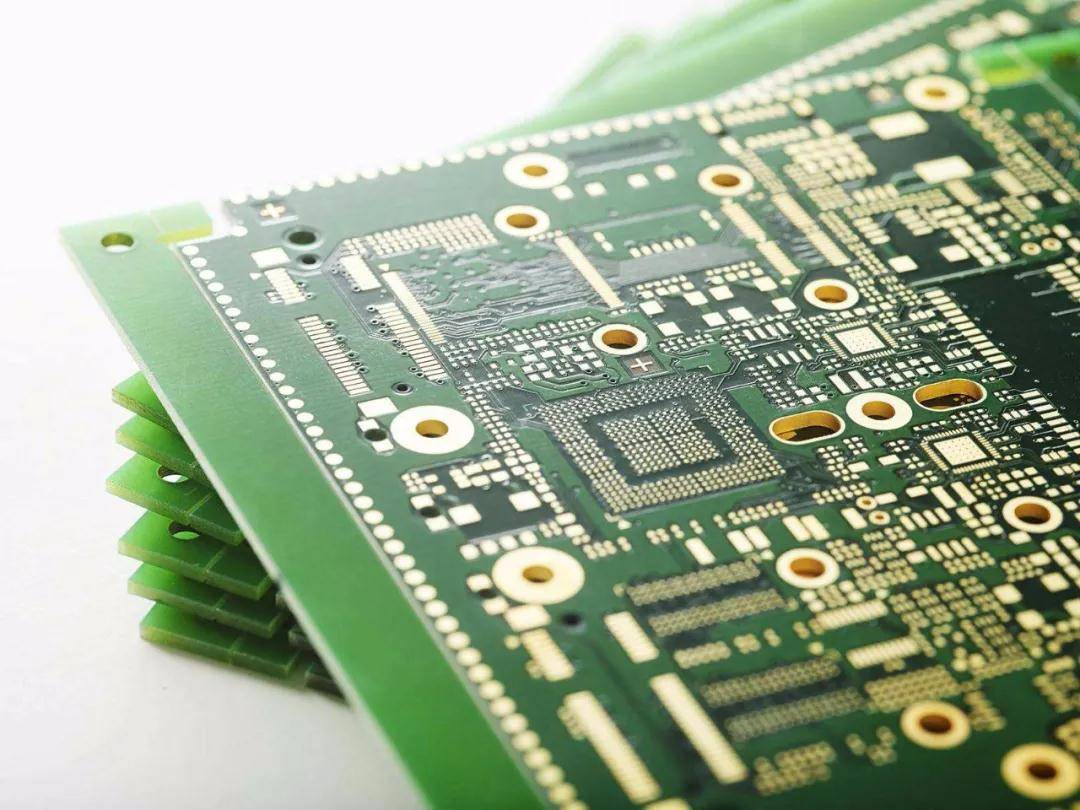

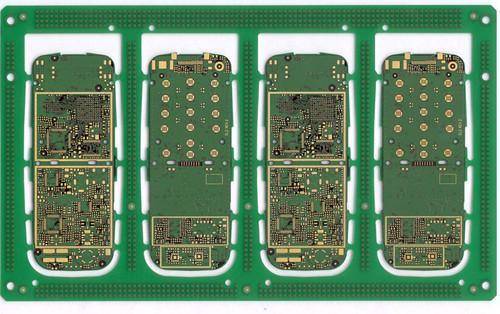

Waad ku xukumi kartaa habka dusha sare ee PCB adigoo eegaya midabka

Halkan waxaa ka mid ah dahab iyo naxaas ah oo ku yaal guddiyada wareega ee taleefannada gacanta iyo kumbuyuutarrada. Sidaa darteed, qiimaha dib-u-warshadaynta ee looxyada wareega ee la adeegsaday waxay gaari karaan in ka badan 30 yuan kiilogaraam. Aad ayey uga qaalisan tahay iibinta waraaqaha qashinka, dhalooyinka quraaradda, iyo bir bir ah. Ka baxsan, lakabka sare ee ...Akhri wax dheeraad ah -

Xiriirka aasaasiga ah ee ka dhexeeya qaabeynta iyo PCB 2

Sababta oo ah astaamaha wareejinta awoodda korantada, way fududahay in la keeno korantada wareejinta awoodda si loo soo saaro faragalinta is-ururinta weyn ee elektromagnetic. Iyada oo ah injineerka korantada, injineerka korantada elektaroonigga ah, ama injineerka PCB, waa inaad fahamtaa Cau ...Akhri wax dheeraad ah -

Waxaa jira inta ugu badan ee 29 cilaaqaad aasaasi ah oo ka dhexeeya qaabeynta iyo PCB!

Sababta oo ah astaamaha wareejinta awoodda korantada, way fududahay in la keeno korantada wareejinta awoodda si loo soo saaro faragalinta is-ururinta weyn ee elektromagnetic. Iyada oo ah injineerka korantada, injineerka korantada elektaroonigga ah, ama injineerka PCB, waa inaad fahamtaa Cau ...Akhri wax dheeraad ah -

Immisa nooc oo ah pcb guddiga wareega ee PCB ayaa loo qeybin karaa iyada oo loo eegayo sheyga? Xagee loo isticmaalay?

Kala-saaridda Qalabka PCB ee guud ahaan waxaa ku jira kuwa soo socda: Bai waxay u isticmaashaa FR-4 (CEM-LOLES LOCEST), Fiber-Cabbosite-ka oo ku saleysan xarkaha ''Akhri wax dheeraad ah -

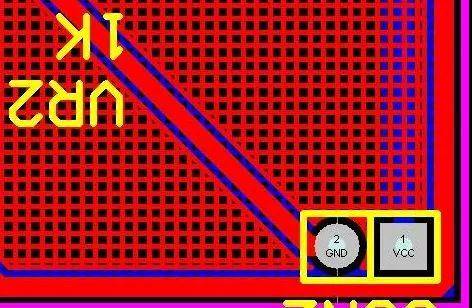

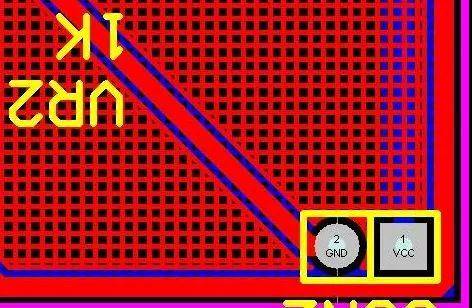

Grid naxaas ama naxaas adag? Tani waa dhibaatada PCB ee mudan inay ka fikirto!

Waa maxay naxaas? Waxa loogu yeero shabeelka naxaasta ah waa in loo isticmaalo booska aan la isticmaalin ee guddiga wareega ee dusha sare ee tixraaca ah ka dibna ku buuxi naxaas adag. Meelahaas naxaasta ah waxaa sidoo kale loogu yeeraa buuxinta naxaasta. Muhiimadda ay leedahay daahan daboolka naxaasta ayaa ah in la yareeyo carqaladeynta safka dhulka iyo in ...Akhri wax dheeraad ah -

Mararka qaarkood waxaa jira faa iidooyin badan oo loo tago PCB Paper Ript ee hoose

Nidaamka naqshadeynta PCB, injineerada qaar ma doonayaan inay naxaas dhigaan dhammaan dusha sare ee lakabka hoose si loo badbaadiyo waqtiga. Tani sax ma tahay? PCB ma tahay inuu noqdo naxaas ah? Marka ugu horeysa, waxaan u baahanahay inaan caddeeno: Xaraashka hoose ee naxaasta ah ayaa faa'iido leh oo lagama maarmaan u ah PCB, laakiin ...Akhri wax dheeraad ah -

Afar astaamood oo aasaasi ah oo ku saabsan PCB Rf Vf

Halkan, afarta astaamood ee aasaasiga ah ee tikidhada soo noqnoqda ee idaacadaha waxaa loo tarjumi doonaa afar dhinac: Idaacadaha Idaacadaha ah, calaamad yar oo ra'yi gelin ah, iyo qodobada muhiimka ah ee u baahan feejignaan gaar ah habka naqshadeynta PCB-ga ar ...Akhri wax dheeraad ah -

Guddiga Xakameynta Gudiga

Guddiga kantaroolka sidoo kale waa nooc ka mid ah guddiga wareega. In kasta oo tirada codsigu uusan u ballaadhin sida guddiyada wareegga, ay tahay mid ka caqli badan oo ka badan otomaatig ka badan guddiyada wareegga caadiga ah. Si fudud loo dhigo, guddiga wareega ee u ciyaari kara door xakameeya waxaa loo yaqaannaa guddiga kontoroolka. Gudiga xakameynta I ...Akhri wax dheeraad ah