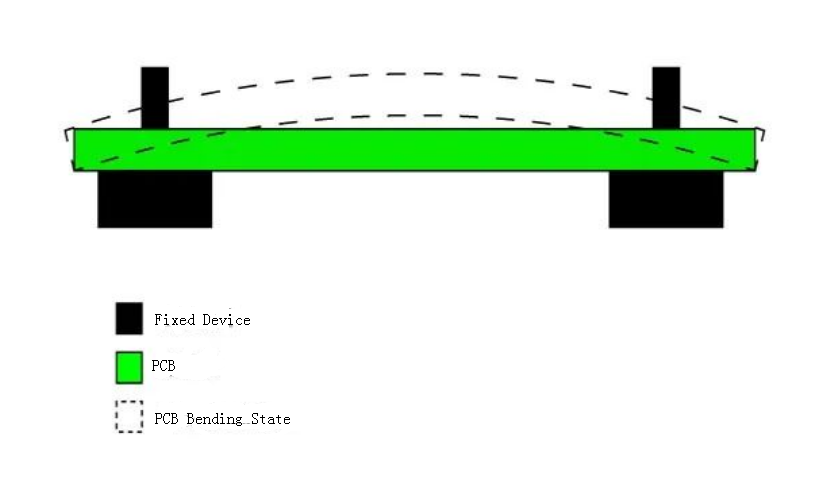

Muchokwadi, PCB warping zvakare inoreva zvakare kukotama kwedunhu redunhu, iyo inoreva iyo yekutanga flat wedunhu redunhu. Kana yakaiswa pane desktop, iwo maviri magumo kana pakati pebhodhi anoonekwa zvishoma kumusoro. Ichi chiitiko chinozivikanwa sePCB warping muindasitiri.

Fomula yekuverenga iyo yehondo yedunhu ndeyekuisa dunhu redunhu flat pane tafura ine makona mana eboka redunhu pasi uye kuyera kukwirira kweArch pakati. Fomula iri seinotevera:

Warpage = kureba kweiyo arch / kureba kwePCB refu divi * 100%.

Circuit Board Warpage Industry Standard: Maererano neIPC - 6012 (1996 Edition) "Kufunga kwekucherechedzwa kwekurwadzisa Nekuda kwekugona kwakasiyana kwekugona kwefekitori yega yega, kune zvakare mamwe mutsauko muPCB warpage control zvinodiwa. For 1.6 bhodhi yakasarudzika yakajairika-sident cort cirdit madunhu, vazhinji vemitambo yeCocroction

Maitiro Ekudzivirira Kurova kweDhiri Board panguva yekugadzira?

(1.

.

(3.

Maitiro Ekudzivirira Dunhu Board Waring?

1.Kuneering Dhizaini: Interlayer Semi-Kudza Srour Grongwa inofanira kunge yakakodzera; Multilayer Core bhodhi uye sheyo-yakaraswa pepa rinogadzirwa kubva kune mumwe mutengesi; Iyo nzvimbo yemifananidzo yeiyo yekunze C / s ndege iri padyo sezvinobvira, uye iyo yakazvimirira grid inogona kushandiswa.

2.Drying Plate isati yasviba: Kazhinji madhigirii gumi nemashanu maawa 6-10, kunze kwemvura yemvura mundiro yemvura mundangoro, kuenderera mberi nekuporesa muridzi rizere, bvisa kushushikana mundiro; Baking sheet usati wavhura, zvese zvemukati layer uye kaviri kudivi rinodiwa!

3.BEFISINA LAMATIONS, KUTENDA KWAZVO ZVINOGONESWA KUTI KUTI KUTI KUTI KUTI KUTI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUTI URI KUPEDZESA ISHURE YEMAHARA; Iyo core ndiro inofanirwawo kuteerera kune iyo nzira yeWarp uye Weft; Kutungamira kwakawanda kweplate kupora pepa ndiko kutungamirirwa naMeidian; Kutungamira kwenguva refu kweiyo mhangura yakakora ndiro ndeye maredional; 10 maratari e 4oz simba rakakomberedza bhokisi renjodzi

4.Kutsiga kwekumwedza kubvisa kushushikana mushure mekutonhora, kucheka mutsara wedzinza;

5S.S.S.KAKUSHURE PASI PASI PASI PASI PASI: 150 madhigirii maawa mana;

6.Zvakaipa zviri nani kuti urege kusvika pakucheka kwebrashi, kuchenesa chemakemikari kunokurudzirwa; Special Fixture inoshandiswa kudzivirira iyo ndiro kubva kukotama uye kupeta

7.After Spelly Tin paFlat Marble kana Steel Plate Conline kutonhora kumhepo tembiricha kana mhepo inoyerera pamubhedha inotonhorera mushure mekuchenesa;