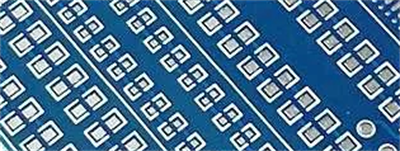

1. Square Pad

Zvinowanzoshandiswa kana zvikamu zviri pabhodhi rakadhindwa zvakakura uye zvishoma, uye mutsara wakadhindwa wakareruka. Kana uchigadzira PCB neruoko, uchishandisa iyi Pad iri nyore kuzadzisa

2.Round Pad

Mabhodhi akadhindwa nemativi uye akaiswa kaviri, zvikamu zvakarongedzwa nguva zhinji. Kana iyo density yebhodhi inobvumira, mapuru anogona kunge akakura uye haazoperi panguva yekutengesa.

3. Island Shaudera Pad

Iyo Pad-to-pad-pad-padhuzana yakabatanidzwa. Inowanzoshandiswa mune vertical isroregular gadziriro yekuisa.

4. Polygon Pad

Izvo zvinoshandiswa kusiyanisa ma gatsiti neyakafanana kwekunze madhiri uye akasiyana gomba diamita, ayo ari nyore kugadzirisa uye kugungano

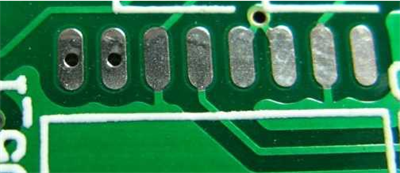

5. OVEL PADTHE Pad ine nzvimbo yakakwana yekuwedzera iyo anti-gropping kugona, kazhinji inoshandiswa mune dial in-line midziyo

6.open-akaumbwa pad

Kuti uve nechokwadi chekuti mushure mekunge mushure mekunge mawuri kutengesa, matanda emadondo ekurinda anotengeserana haazivharwe nemutengesi.

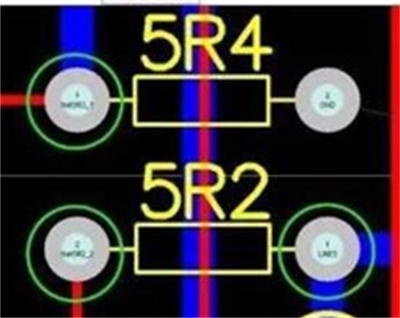

7. Yambuka Pad

MaPRD-akaumbwa akaumbwa anonziwo mapads, etcc.

● Kana mapuru ako ari pasi. Ruva remuchinjiko-remuchinjiko rinogona kuderedza nzvimbo yekubatanidza yemahota aya, kuderedza kupisa kwekushambadzira kwekunyepedzera, uye kufambisa nzizi.

● Kana PCB yako ichida kuiswa kwemushini uye inoda muchina wekuparadza, iyo muchinjiko-yakaumbwa pad iyo inogona kudzivirira iyo PCB kubva kuBeeling kubva (nekuti kupisa kwakawanda kunodiwa kunyungudika

8. Teardrop pad

Izvo zvinowanzo shandiswa apo iyo trace yakasungirirwa kune liner yakatetepa, kudzivirira kutarisa kweiyo liner uye kudzikisira kwechirevo kubva muchinjenya. Iyi liner inowanzoshandiswa mune yakakwirira masaga