Mune welding ye-two-layer circuit board, zviri nyore kuva nedambudziko rekunamatira kana virtual welding. Uye nekuda kwekuwedzera kwemaviri-layer redunhu redhisheni zvikamu, imwe neimwe yemhando yezvikamu zvewelding zvinodiwa welding tembiricha uye zvichingodaro hazvina kufanana, izvo zvinotungamirirawo kukuwedzera kwekuoma kwekushongedza huviri-layer circuit board, kusanganisira welding order. mune zvimwe zvigadzirwa zvine zvinodiwa zvakasimba.

Maitiro ekuita maviri-sided circuit board welding:

Gadzirira maturusi uye zvinhu, kusanganisira mabhodhi edunhu, zvikamu, solder, solder paste, uye simbi yekusimbisa.

Chenesa bhodhi repamusoro uye mapini echikamu: Chenesa nzvimbo yebhodhi uye mapini echikamu nedetergent kana doro kuti uve nechokwadi chewelding kunaka uye kuvimbika.

Zvikamu zvenzvimbo: Isa zvikamu pabhodhi redunhu maererano nezvinodiwa zvekugadzira bhodhi redunhu, uchiteerera kukutungamira uye chinzvimbo chezvikamu.

Isa solder paste: Isa solder paste kune padhi pane chikamu mapini uye redunhu board mukugadzirira welding.

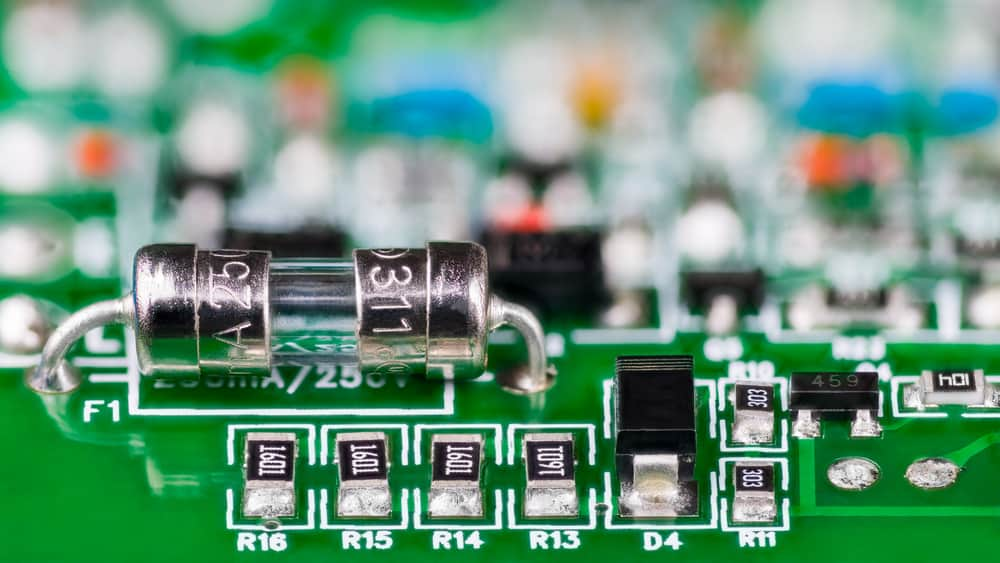

Welding components: Shandisa yemagetsi solder iron to weld components, teerera kuchengetedza tembiricha yakagadzikana uye nguva, dzivirira kupisa kwakanyanya kana welding nguva yakarebesa.

Tarisa mhando yewelding: tarisa kana iyo welding point yakasimba uye yakazara, uye hapana virtual welding, leakage welding uye zvimwe zviitiko.

Kugadzirisa kana kuwedzeredza: Kune welding mapoinzi ane hurema hwewelding, gadziriso kana rewelding inodiwa kuti ive nechokwadi chewelding mhando uye kuvimbika.

Circuit board welding tip 1:

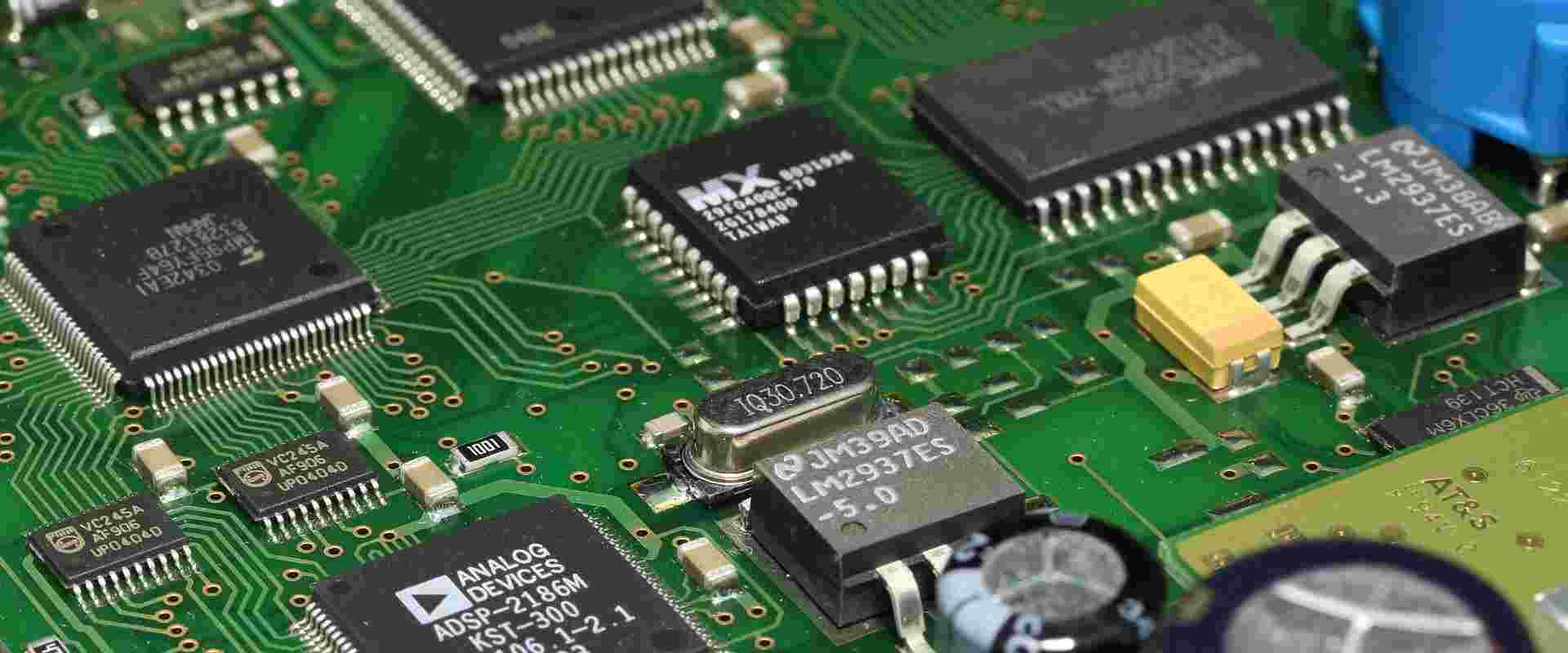

Iyo yekusarudza welding process inosanganisira: flux spraying, redunhu bhodhi preheating, dip welding uye dhonza welding. Flux coating process Iyo flux coating process inoita basa rakakosha mukusarudza welding.

Pakupera kwekupisa kupisa uye welding, iyo flux inofanirwa kuita zvakakwana kudzivirira chizvarwa cheBridges uye kudzivirira oxidation yedunhu bhodhi. Flux kumwaya Bhodhi inotakurwa neiyo X / Y manipulator pamusoro pemvura inoyerera, uye iyo inoyerera inopfapfaidzwa pane pcb board welding chinzvimbo.

Circuit board welding tip 2:

Kune microwave peak inosarudzika welding mushure mekuita reflow soldering process, zvakakosha kuti iyo flux yakapfapfaidzwa nemazvo uye iyo microporous spray type haizosvibisa nzvimbo iri kunze kwejoint ye solder.

Iyo dhayamita yenzvimbo yeiyo micro-spot yekupfapfaidza flux yakakura kupfuura 2mm, saka chinzvimbo chechokwadi cheiyo flux yakaiswa pane redunhu board ndeye ± 0.5mm, kuitira kuti ive nechokwadi chekuti flux inogara yakavharwa pane welding chikamu.

Circuit board welding tip 3:

Iyo maitiro maitiro ekusarudza welding anogona kunzwisiswa nekuenzanisa neave soldering, musiyano uri pachena pakati pezviviri ndewekuti chikamu chezasi chebhodhi redunhu mune wave welding inonyudzwa zvachose mumvura solder, nepo mukusarudza welding, chete dzimwe nzvimbo dzakananga. vari kusangana ne solder wave.

Sezvo redunhu bhodhi pachayo ari urombo kupisa kutamisa svikiro, hazvizopi kupisa uye kunyungudutsa solder majoini munzvimbo yakatarisana zvinoumba uye redunhu bhodhi kana welding.

Iyo flux inofanirawo kuve yakavharwa isati yaiswa welding, uye kana ichienzaniswa neave soldering, iyo flux inongoputirwa pazasi pebhodhi kuti isungirwe, pane iyo pcb board yese.

Pamusoro pezvo, kunyungudika kwakasarudzika kunongoshanda chete kune welding yeplug-in components, kusarudza welding inzira itsva, uye kunyatsonzwisisa kwekusarudza welding process uye midziyo inodiwa kuti ubudirire welding.

Kaviri-sided circuit board welding inoda kuitwa zvinoenderana neyakatsanangurwa nhanho dzekushanda, teerera kuchengetedzeka uye kutonga kwemhando, uye kuve nechokwadi chewelding mhando uye kuvimbika.

Double-sided circuit board welding inoda kutarisisa zvinhu zvinotevera:

Usati welding, chenesa redunhu bhodhi pamusoro uye chikamu mapini kuti ive nechokwadi welding kunaka uye kuvimbika.

Zvinoenderana nezvinodiwa zvekugadzira bhodhi redunhu, sarudza akakodzera maturusi emagetsi uye zvinhu, senge solder, solder paste, nezvimwe.

Usati welding, tora ESD matanho, sekupfeka ESD mhete, kudzivirira electrostatic kukuvara kune izvo zvikamu.

Chengetedza tembiricha yakatsiga uye nguva panguva yekugadzira welding kuti udzivise kupisa kwakanyanya kana nguva yakareba yewelding, kuti usakuvadza bhodhi redunhu kana zvikamu.

Iyo welding process inowanzoitwa maererano nekurongeka kwemidziyo kubva pasi kusvika kumusoro uye kubva kudiki kusvika kuhombe. Kunyanya kupihwa kune welding integrated circuit machipisi.

Mushure mekunge welding yapera, tarisa welding quality uye kuvimbika. Kana paine chero chakakanganisika, gadzirisa kana wedzera weld nenguva.

Mune chaiyo welding oparesheni, kukwenenzverwa kwekaviri-sided redunhu bhodhi kunofanirwa kunyatso kuenderana neakakodzera maitiro ekuita uye mashandiro ekuita kuti ive nechokwadi chemhando uye kuvimbika kwewelding, uchiteerera kune yakachengeteka kushanda kudzivirira kuzvikuvadza pachayo uye kwakatenderedza. zvakatipoteredza.