HDI: Yakakwira Density Interconnection yePfupi, High-dentity Interconnection, LITELOT HOLT MUNYAYA YEMADZIMAI YEMAHARA

Bofu via: Pfupi kwemapofu kuburikidza, anoziva kubatana kwemukati pakati pemukati uye ekunze zvikamu.

Kuvigwa Via: Pfupi yekuvigwa kuburikidza, ichiziva kubatana pakati peiyo yemukati dura uye iyo yemukati.

Bofu vave bofu chete gomba rine dhayeti re 0.05mm ~ 0.15mm, inovigwa kuburikidza ne laser, uye inowanzoumbwa neLaser, iyo yakakamurwa kuita CO2 uye yag ultraviolet laser (uv).

HDI Board zvinhu

1.hdi Plate Manyorero Rcc, Ldc, Fr4

RCC: Pfupi yeResin yakachekwa mhangura, resin yakaumbwa mhangura foil, rcc yakaumbwa nemhangura foil uye kupisa, kupokana, etc.

Iyo resin layer yeRCC ine maitiro akafanana seFr-1/4 mabhegi akasungwa (prefreg). Pamusoro pekusangana nezvinobvumirwa zvinofanirwa kuita zvechirongwa zveiyo multilayer bhodhi yeiyo nzira yekuunganidza, yakadai se:

(1) Kuvimbika kwakakwirira uye kuitisa micro-kufambisa.

(2) Girazi rakakwirira rinoshandura tembiricha (tg);

(3) yakaderera dielelectric inogara ichinyima uye yakaderera mvura kutumira;

(4) Kududzirwa kwakanyanya uye simba kune mhangura foil;

.

Panguva imwecheteyo, nekuti Rcc rudzi rutsva rwechigadzirwa pasina girazi fiber, zvakanakira hope dzekutakura ne laser uye rakanakisa kurema uye kuonda kwehuremu hwebhuruu. Uye zvakare, iyo resin yakacheuka mhirizhonga yemhangura yakavhiringidzika misoro yemhangura yakadai se12pm, 18pm, nezvimwe, izvo zviri nyore kuita.

Yetatu, ndeipi yekutanga-kurongeka, yechipiri-yekuraira PCB?

Iyi yekutanga-kurongeka, yechipiri-kurongeka inoreva nhamba yeLaser Holes, PCB Core Board Dzvinyiriro Dzinoverengeka, Kutamba akati wandei laver holes! Mirairo shoma. Sezvinoratidzwa pazasi

1 ,. Kudzvanya kamwe chete mushure mekudhirowa maburi == "kunze kweyekupedzisira kamwe chete ndarira fopper

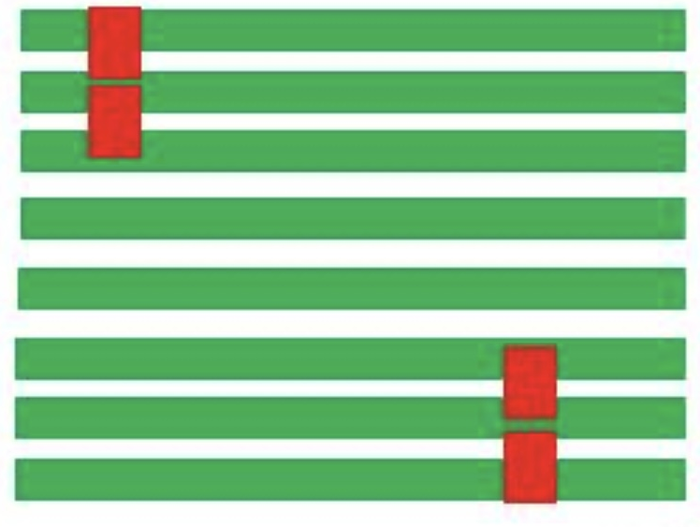

Iyi ndiyo nhanho yekutanga, sezvakaratidzwa mumufananidzo pazasi

2, mushure mekutsikirira kamwechete uye kufambisa maburi == "kunze kweimwe mhangura foil ==" uye yakadonha makomba eimwe ndimwe marara == "uye ipapo laser ichirova maburi

Uku ndiko kurongeka kwechipiri. Inonyanya kungori nyaya yeiyo kangani iwe yaunosiya, ndiyo matanho mazhinji.

Chechipiri kurongeka kunobva kwakakamurwa mumakomba akaiswa uye akapatsanura maburi.

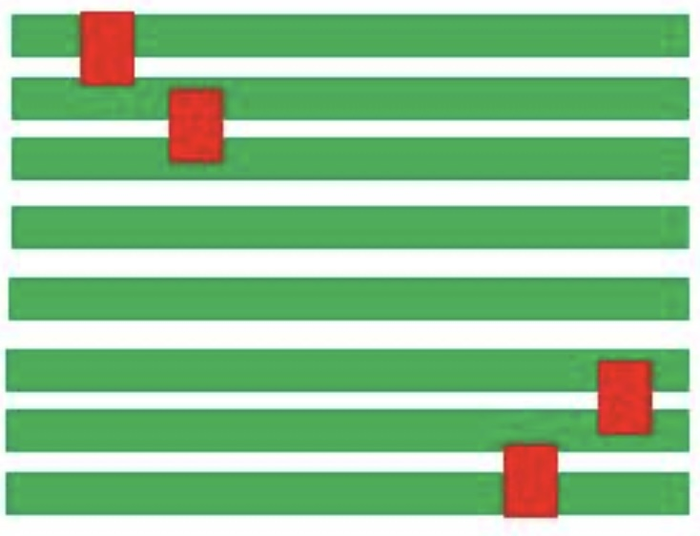

Mufananidzo unotevera ndewe masere ematunhu ezvisere Ipapo mamwe matenga ere 8,8 anomanikidzwa uye akarohwa ne laser maburi zvakare. Uku ndiko kugadzira maviri laser maburi. Rudzi urwu rwegomba nekuti rwakasimudzwa, iyo nzira yakaoma ichave iri padiki, mutengo wakakwira zvishoma.

Nhamba iri pazasi inoratidza maratidziro masere ezvematunhu ezvipfupi ezvisere Asi makomba laser haasimudzwi pamwe chete, kuoma kwekugadzirisa kwakanyanya.

Yechitatu kuraira, yechina kurongeka uye zvichingodaro.