Pamusoro pePCB chimiro uye dambudziko rove, nhasi hatizotaure nezve chiratidzo chekuvimbika kuongorora ( Kungotaura nezve kuongorora kweMugadziri (DFM), kusava nehanya kwekugadzira kugadzirwa kuchatungamirawo kukundikana kwekutadza kwechigadzirwa.

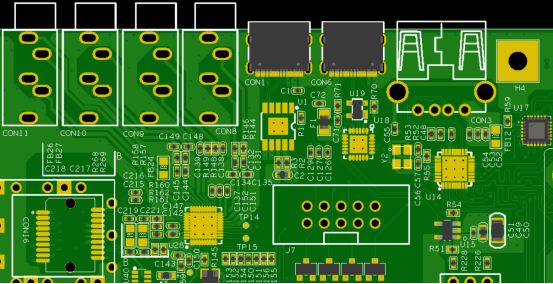

Akabudirira DFM muPCB Rudzi runotanga nekuisa dhizaini mitemo kuaccount yeakakosha dfm matambudziko. Mitemo yeDFM inoratidzwa pazasi inoratidza zvimwe zveContemporary Design Ekugona uko Vagadziri vazhinji vanogona kuwana. Ita shuwa kuti miganhu yakaiswa muPCB Dhizaini Mitemo Usavhiringidza kuitira kuti zvizhinji zvigadziriso zvekugadzira zvinogona kuvezwa.

Dambudziko reDFM rePCB rough rinobva pane yakanaka PCB rondedzero, uye mitemo yekukotama yemitsetse, etceratory majaho, etcalaratory, et. Global Routing Pathitization inoitwa pane waya yairisa kuti igare yekutanga, uye kuremerwa kunoedzwa kuti uvandudze mhedzisiro uye DFM kuumbwa.

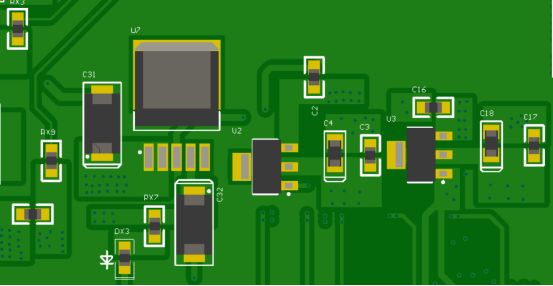

1.smt zvishandiso

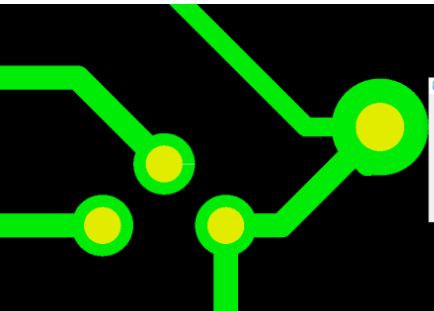

Chishandiso chishandiso chinoparadzanisa zvinosangana nezvinodiwa nemagungano, uye kazhinji zvakakura zvinopfuura 20mil yemamiriro ezvinhu akakwira, 80mili yemidziyo yeIchi, uye 200mi yeBGA zvigadzirwa. Kuti uvandudze kunaka uye goho rekugadzira maitiro, kushanduka kwemhepo kunogona kuzadzisa zvinodiwa negungano.

Kazhinji, chinhambwe pakati peiyo smd mapuru emapuranga emapani anofanirwa kunge akakura kupfuura 6mil, uye kugona kwesimba remutengesi mutengesi Bridge ndeye 4mil. Kana chinhambwe pakati peSMD Pads iri pasi pe6mil uye chinhambwe pakati pawindo renzvimbo isingasviki 4mics

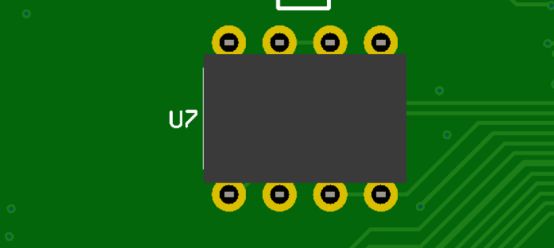

2.Dip mudziyo

Iyo PIN inopararira, kutungamirirwa uye kupatsanurwa kwemidziyo mune pamusoro pekutengesa mawadhi yekuita inofanira kuenderana. Isina kukwana pini yekuparadzaniswa kwechishandiso ichatungamira kuTini tini, iyo ichatungamira kudunhu pfupi.

Vazhinji vagadziri vanodzora kushandiswa kweine-line midziyo (thts) kana vaise kune rumwe rutivi rwebhodhi. Nekudaro, mune-mutsara zvishandiso hazviwanzogoneka. Panyaya yekusanganiswa, kana iyo-mutsara mudziyo uri pamusoro peiyo yepamusoro uye iyo chigamba chishandiso chakaiswa pane yakadzika pasi, mune zvimwe zviitiko, ichakanganisa iyo-side-side the waternering. Mune ino kesi, inodhura-inodhura maitiro, yakadai sekusarudza tulating, inoshandiswa.

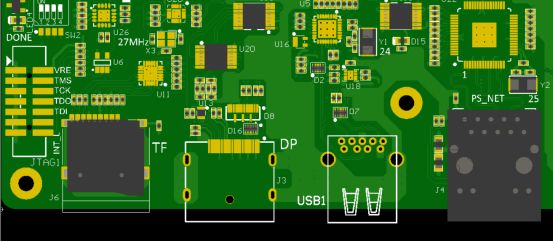

3.Kwe kure pakati pezvikamu uye pamucheto weplate

Kana iri muchina welder, chinhambwe pakati pezvikamu zvemagetsi uye nemucheto webhodhi zvinowanzoita 7

Nekudaro, apo pamucheto weplate hunoputika, unogona kusangana neyechitima chechitima chemuchina uye kukuvadza zvikamu. Iyo kosi yekudzikwa pamucheto weplate ichabviswa mukugadzira maitiro. Kana iyo pad iri diki, iyo nzira yeMulting ichakanganiswa.

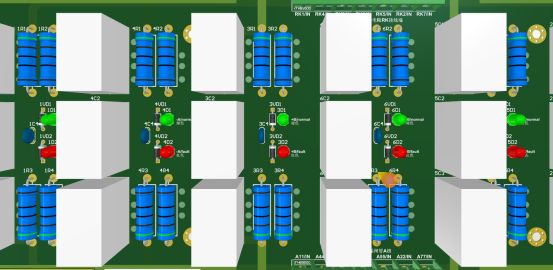

4.Distance yemidziyo yakakwira / yakaderera

Kune marudzi mazhinji ezvikamu zvemagetsi, maumbirwo akasiyana, uye mitsara yakasiyana siyana, saka kune misiyano iri muungano yekodhi yemapuranga akadhindwa. Rwiyo rwakanaka harugone kungoita mushini wakagadzikana kuita, kuvhundutsa chiratidzo, kuderedza kukuvara, asi zvakare kunogona kuwana yakachena uye yakanaka mhedzisiro mukati mechina.

Zvishandiso zvidiki zvinofanirwa kuchengetwa pane imwe chinhambwe chakatenderedza midziyo yakakwirira. Chishandiso chinhambwe kune mudziyo urefu ratio chidiki chidiki, pane isina kujairika yekupisa mafungu, iyo inogona kukonzera njodzi yekuremerwa kana kugadzirisa mushure mekugadziriswa mushure mekutora.

5.Wicsion kune mudziyo kupatsanurwa

Muzvizhinji Smt kugadziriswa, zvinodikanwa kuti utarise zvimwe zvikanganiso mukukwira kwemuchina, uye kufunga nezve nyore nyore kwekugadzirisa uye kuongororwa kwekuona. Izvo zviviri zvikamu zvepedyo hazvifanirwe kunge zviri padyo uye chimwe chinhambwe chinofanira kusiiwa.

Iko kuparadzaniswa pakati pezvikamu zveFlake, Sot, Soichi uye Flake zvikamu ndezve 1.25mm. Iko kuparadzaniswa pakati pezvikamu zveFlake, Sot, Soichi uye Flake zvikamu ndezve 1.25mm. 2.5mm pakati pePlcc uye flake zvikamu, zvine chokwadi uye qfp. 4mm pakati pePlccs. Paunenge uchigadzira zvigadziko zvePlc, chengetedza chinofanira kutorwa kuti ubvumire saizi yeiyo plcc socket (iyo plcc pini iri mukati mezasi kweiyo socket).

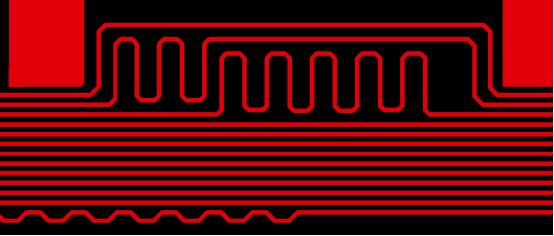

6.line upamhi / mutsara kure

Kune vagadziri, mukugadzira dhizaini, hatigone kungofunga nezvechokwadi uye kukwana kwezvinhu zvinodikanwa zvegadziriro, pane kurambidzwa kukuru ndiko kurambidzwa uku. Izvo hazvigoneke kuti fekitori yebhodhi kugadzira mutsara mutsva wekugadzira wekuzvarwa kwechigadzirwa chakanaka.

Mumamiriro ezvinhu akajairwa, mutsara wezana wehupamhi wemutsara unodzorwa kune 4 / 4mil, uye gomba rakasarudzwa kuve 8mil (0.2mm). Chaizvoizvo, anopfuura 80% yePCB Vagadziri vanogona kubereka, uye mutengo wekugadzira ndiyo yakaderera. Iyo shoma mutsara upamhi uye mutsara wekureba unogona kudzorwa kusvika ku3 / 3mil, uye 6mil (0.15mm) inogona kusarudzwa kuburikidza negomba. Chaizvoizvo, zvinopfuura 70% PCB Vagadziri vanogona kuigadzira, asi mutengo wakakwira zvishoma pane yekutanga nyaya, kwete yakanyanya kukwirira.

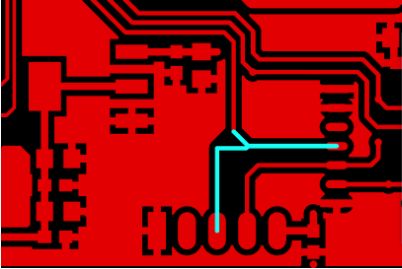

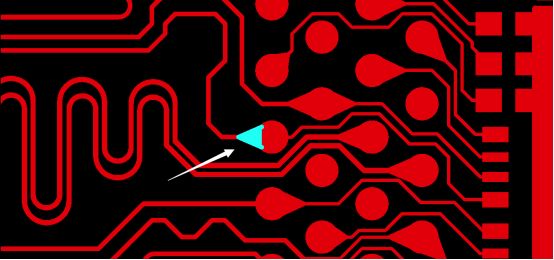

7.an acute angle / kurudyi kona

Sharp angle routing inowanzo kurambidzwa mune wiring yeaya Nekuti kutendeka kwechiratidzo chiratidzo chinokanganiswa, iyo yekurudyi-wiring ichapa inogadzira imwe parasitic kugona uye kureverera.

Mukuita kwePCB Plate-Kugadzira, PCB waires inopinda pakona yakaoma, iyo ichaita kuti dambudziko rinonzi acid angle. MuPCB Dunhu rinenge redunhu, rakawandisa reCRD redunhu richakonzerwa ne "acid angle", zvichikonzera PCB Dunhu Gumi Dunhu Rekutambudzika. Naizvozvo, PCB mainjiniya anofanirwa kudzivisa kupinza kana kushamisa makona mune wiring yewiring, uye chengetedza devie 45 pakona pakona yeashandisa.

8.Chop Strip / Island

Kana iri nzvimbo yakakura yakakwana yechitsuwa, ichava antenna, iyo inogona kukonzera ruzha uye kumwe kupindira mukati mebhodhi (nekuti mhangura yaro haina kuverengerwa - ichava chiratidzo chemagashori).

Mitunhu yemhangura uye zviwi zviwanikwa zviyero zvizhinji zvematehwe ezvekuvhara-marara, izvo zvinogona kukonzera mamwe matambudziko akakura muakaruki pachiwi. Diki vadiki ratanga vazivikanwe kuti vazivise kupaza PCB Panel uye vanofamba vachienda kune dzimwe nzvimbo dzekutarisirwa papaneri, vachikonzera dunhu pfupi.

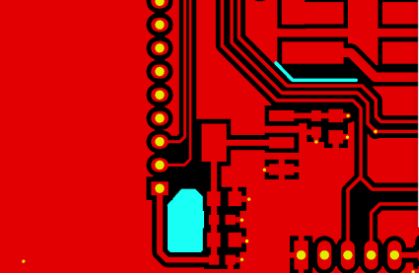

9.Hele rin'i yekukwevera maburi

Iyo gomba rin'i rinoreva mhete yemhangura kutenderedza gomba rekukwezva. Nekuda kwekushivirira muitiro wekugadzira, mushure mekudhirowa, kana kuridza mhere, uye mhangura mhangura kutenderera gomba hakuwanzo kurova nzvimbo yepakati, iyo inogona kukonzera iyo gomba rin'i kuputsa.

Rutivi rumwe rwegomba rwiyo runofanira kuva rukuru kupfuura 3.5mil, uye plug-in gomba rin'i inofanira kunge yakakura kupfuura 6mis. Iyo ridza renyeti idiki. Mukuita kwekugadzira uye kugadzira, gomba rekuchera rine mishonga uye kuwirirana kwemutsara zvakare kune zvibvumirano. Kutsauka kwekushivirira kuchatungamira kugomba rin'i rinoridza redunhu rakavhurika.

10.Reger madonhwe ewiring

Kuwedzera misodzi kuPCB inogona kuita kuti dunhu rive rekutenderera pcb yakagadzikana, kuvimbika kwakanyanya, kuitira kuti system ichave yakagadzikana, saka inofanirwa kuwedzera misodzi yedunhu.

Kuwedzerwa kwemadonhwe madonhwe kunogona kudzivirira kuderedzwa kweiyo nzvimbo yekuonana pakati paWire uye Pad kana iyo waya uye iyo yekutyaira yedunhu kana iyo dunhu board yakakanganiswa neyakafara simba rekunze. Paunenge uchiwedzera misodzi inodonhedza kuti udzivirire, dzivirira kuputika kwemari yakawanda kuti ubvise padura, uye dzivisa kusagadzikana uye marara zvinokonzerwa negomba degle panguva yekugadzira.